Living with "Trevor"

As this machine is now in service there will be adjustments and details to attend to. This is the record.

April 2018.

Mark returned from Germany and met Trevor for the first time. Pleasingly they get along spiffingly well, and Mark made some very pleasing observations about the finished product and more importantly - the riding experience. He seemed to feel that Trevor was as remarkable as I do. The total assembly that Trevor now is provides a rather surprising package. Performance is crisp and responsive, handling is impeccable and gives the impression of having lost much more weight than we can find reason for. Starting has been somewhat perplexing when cold, and we feel it may be an unhappy Boyer ignition that is responsible - especially as Mark did a lot of carb tuning in his brief time here and we feel that the fuel situation is above suspicion. Despite fitting 4 volt coils to the Boyer no improvement was gained, and when strobe timing the ignition feels to be somewhat too advanced even when using the correct marks and revs. A Trispark has been purchased and will be fitted very soon as a final check of the ignition system in general.

Despite the rather wintry climatics, Mark took advantage of every opportunity to give Trevor some stick.

Beam me up..

Thanks to Mark's obvious enthusiasm the total mileage is now over 700 and Trevor has been treated to another new oil filter and a healthy serving of Mobil 1 Vee Twin 20/50 full synthetic. I am pleased to report that the cold start oil pressure is 125psi on the synthetic - which I feel is somewhat healthier than the pressures I had recorded on cold mineral oil and which I thought were a tad too high. I feel that this is also conclusive evidence that synthetic oil - even of the same rated viscosity - flows more freely than similar mineral oil when cold.

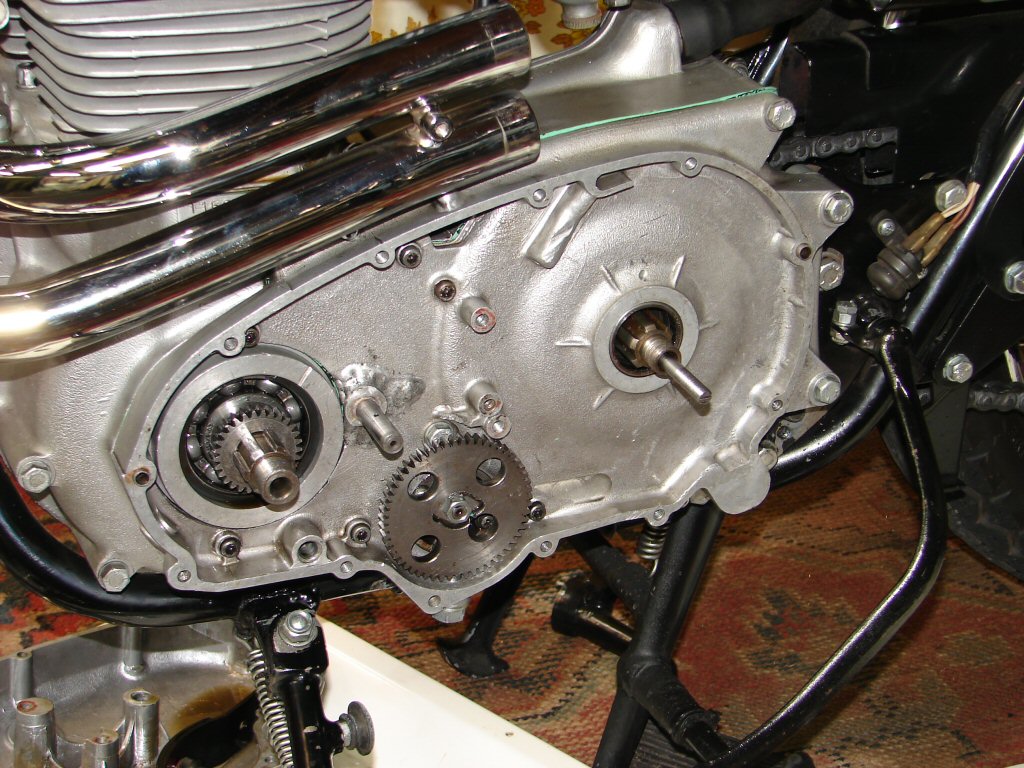

One other event. A small but annoying oil leak had started from the primary drive area. I was suspicious that the non-standard inner primary chaincase may have cracked around it's rather unprofessional welding, but on removal there was no evidence of such. What was apparent was that a number of the fastening threaded holes between outer and inner cases had been broken through, apparently by previous use of screws that were too long. The solution would hopefully be no more demanding than the use of sealant on a number of the fasteners to prevent any oil seeping down the threads. This was done.

Quality control applied to inner chaincase..

Unfortunately the new ignition unit did not arrive in time for it to be fitted before Mark returned to Germany. My fault - I forgot that the Trispark+freight would exceed the NZ$400 limit after which NZ Customs would snaffle it and demand ransom. They did, but only after weeks of silence during which time I had traced the parcel to their place. My efforts to elicit some action apparently fell on deaf ears.

I finally received a letter from Customs with details of taxes owing, so I paid it immediately online and the parcel arrived 4 days later. I had already removed the mufflers and tailpipes in anticipation, and because I did not wish to use the bike again with the Boyer fitted. Something not quite right with it I feel.

The fun begins..

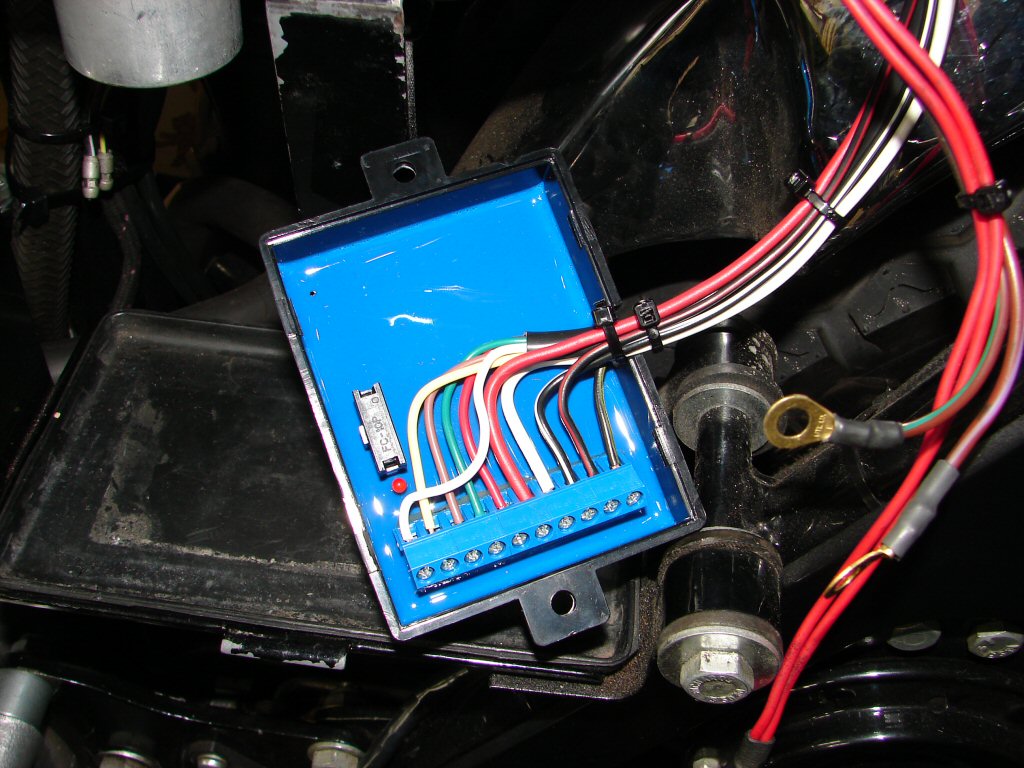

First job was to locate a position for the new Trispark box to be mounted. The Boyer unit had been velcroed to the back of the upright behind the battery tray, and with some judicious manipulation I found that the Trispark could inhabit the same space, albeit on a diagonal. However, this would also allow using cable ties through the two mounting holes of the box to wrap around the upright and prevent any movement. The velcro was left in place to act as a vibration isolator.

While making a wiring loom for the Trispark I also moved the original fuseholder to a new position under the seat, as well as housing a new fuse for the Trispark alongside. The only other change was to fit 12 volt coils instead of the 4 volt jobs we had tried to rev the Boyer up a bit. These coils are original Lucas units as would have been fitted to this bike when it was originally assembled at the factory - so that feels kinda right.

Fuses amidships, new loom awaits Trispark box..

I allowed enough length to the wiring to make it a user-friendly exercise to connect all the wires to the Trispark box whilst in the battery space.

All present and correct..

I temporarily fitted a battery and made sure I had the timing in pretty much the right place by using the LED on the box before closing the box up and attaching it to the battery tray upright. There were no problems fitting it although nor was there any extra space.

I then fitted the battery and secured all connections, remembering to also attach a remote lead for use with a Motobatt charger system. The lead will reside under the seat but can extend from under the seat for easy connection.

With all of that sorted I was able to restore the sidecover which is normally held prisoner behind the exhaust system on this bike, but which will hopefully now remain in place for a long and trouble-free time.

Hiding the ugly bits..

The exhaust manifold had come loose because of several manoeuvres involving the tailpipes and mufflers, so I removed it as far as is possible, cleaned off the old sealant, applied new stuff, then tightened everything in sequence from front to rear. There is a tendency to spring the manifold as the mufflers sit somewhat further outboard than would be optimum and so apply some pressure as they are pulled inboard by their mountings.

They sure look pretty amazing once in place though.

Chrome for Africa..

I shall now not touch it until all the sealant has cured, which in current ambient temps may take 3 months. I did refit the heat shield so that everything is done on this side.

Finit..

The final bit will be to run the bike up and use a strobe light to fine tune the ignition. For this reason I have left the timing aperture open meantime. I have also applied some white Humbrol enamel (model paint) to the "B" mark on the alternator rotor in the No.1 cylinder position which will make observing the mark under strobe light a lot easier.

I do have 3 sparks available however, as I removed the plugs and laid them on the head while kicking the bike over. Nothing left to chance.

The finishing touch..

In a nice piece of serendipitous good planning, Mark had replaced the spark plugs with Iridium type while trying to elicit some better behaviour from the old Boyer. The Trispark unit requires some form of RF suppression and this bike had none as the spark caps are simply dust caps and the leads are copper. While I had the plugs out I noticed that they have an "R" in their part number, meaning they are resistor plugs which will perform that particular function.

So that's nice..

A number of final improvements were undertaken.

Under normal riding conditions a problem had arisen with the front brake. It shuddered badly. Mark thought it might be a symptom of wear in the fork sliders, but I was more of the opinion that it was to do with the disk. I changed the front wheel for one from another rebuild project and immediately the problem was gone. What was more - I got an immediate comparison between an ancient profile Dunlop TT100 front tyre to a modern Dunlop Arrowmax - albeit 25 years old. The transition was remarkable, and despite my misgivings that this 25 year old unused tyre might have degraded, it proved to be an example of the most reassuring cornering that I now remember having discovered when I first dispensed with a TT100 on the front of my own daily ride T160 about 27 years ago. Revelation. Makes you want to attack corners with a gusto you had previously not been up to.

A hard cold starting problem which had been diagnosed by me as lean slides was addressed by removing about 20 thou from the bottom of the slides. The slides had been brass sleeved during the original restoration in the 1990's, which meant that no original parts would now fit. The new exhaust and the use of velocity stacks had both contributed to leaner mixture so this was the only route to salvation. Happily the results were definitely better and cold starting was improved immensely.

Today I finally delivered this machine to it's home. As it will be idle for many months I let it cool and coated most of it to a good spray of WD40 before lashing it down in it's shed. I am very happy with it's current state of everything and look forward to some spirited riding in the company of it's owner at the next opportunity.

Complete.

The bike is now tied down in a small shed with 4 other tasty bikes - all are restrained in case another earthquake tries to upset them.

At this point in time they are all up to scratch and should deliver a fantastic riding experience for their appreciative owner.

I will be there to keep him honest.!

Finished with engines, 15 August 2018.

Cheers, Kilroy.