2009 Alfa Romeo 147 2.0 twinspark.

I bought another Alfa 147 in January 2020 in fabulous condition, 2009 5-door 2 litre TS 5 speed manual with 78,000km, previously owned by an old chap like me who was fastidious with it.

On the 250 mile trip home I was quite certain that this like new car was seriously down on performance compared to our 2003 model - similar specs except 3 door - acceleration was somewhat lacking in enthusiasm but things improved as the revs gradually built up.

When Sue - yes that's Sue - began using it around town, a number of scary things began to happen. When accelerating briskly to get into traffic, the car would slow suddenly, almost as if you had applied brakes, regardless of the accelerator pedal still being at say half travel, and a number of faults began appearing on the dash - traction control, ABS/VDC failure, ECU failure, audible alerts and a red hazard light. The car would still drive on low throttle settings, although would do the same thing again if revs reached around 3500rpm.

After a couple of stop and start cycles everything would return to normal and all the fault lights would gradually turn themselves off. The problem would return when the car got hot and a fair bit of pedal was in use.

I bought a Fiat/Alfa OBD scanner from Amazon, an iCarsoft i950, and it arrived 2 weeks later. It was very easy to operate and I found 3 fault codes logged up. I do not have the codes now, but the faults were - accelerator pedal position sensor faulty/MAF sensor faulty/accelerator pedal position sensor wiring fault circuit B. I figured 'circuit B' meant in the engine bay as I had read of people with a 'circuit A' fault being a connector behind the glovebox on some models.

I cleaned the multi-pin connector at the throttle body, as it was the only connector I could find in that circuit without removing the accelerator pedal assembly, and I fitted the MAF sensor from the other Alfa. Neither of these things cured the fault.

From my experience of working on things mechanical - but not computers - I had found that many times if you just study things carefully you very often discover something amiss.

So I did.

And I did.

This rather innocuous piece of sound proofing should have been fastened by the rather obvious screw you can see to the left, and on inspection the material was perfectly intact where the screw would be. Why would someone deliberately fully fit the screw while leaving the sound proofing only partially attached.?

It was a 30 second job to fit the offending cover as it should be.

I will add something here that had been an impression I was forming from the history I had for this car, which included a number of detailed receipts from the previous owner's usual service agency, compared to what I had found on the car. 'Gary' had told me that he used to supply parts to said agency to have them fitted, as the agents charged a lot more money than he could buy the same parts for himself. Not an uncommon issue these days. He had supplied two new rubber mounts for the muffler most recently, and yet within the first couple of weeks of my ownership I had noticed as Sue drove away that the muffler was waggling about quite noticeably. When I looked at it, the original mounts were still in place and someone had merely put a couple of cable ties around the fractured rubbers. Presumably the agents kept Gary's rubber mounts.

So now we know the game, here is what I discovered behind the piece of sound deadening..

Yes folks - that is the air intake.

And then I thought, hmmm, the ECU knows that there is not enough airflow for the amount of accelerator pedal in use, therefore it suggested the three fault conditions as probable cause - which is about as close as diagnostics ever get anyway, but it gets you to the ballpark.

Now - I can not provide any explanation as to why a mechanic would totally ignore the partially retained sound proofing, nor that it would not have been obvious that it was restricting the air intake. I can only view this as deliberate sabotage. That is why I am not naming the agency, but I know who they are, and I did warn Gary that they were not worthy of his trust with his current vehicle.

The very next thing I did was to release the top portion of the cambelt cover just to make sure that there was a relatively new cambelt in place, as it had been fitted only a few 100km ago, and was greatly relieved to see that it had in fact been done.

The car was now all of what it should have been, and continues to be. We have enjoyed it immensely and it has only needed tyres, upper front suspension arms and a new battery in the intervening 5 years, which may give you all a clue as to the next item I wish to report on.

The cambelt.

The factory owners handbook recommends changing the belt at 60,000km, and as of August 2024 we had put an extra 53,100km on it since the last change, so I was aware that it was coming up.

I was also aware that many well-intentioned self-proclaimed 'experts' - the ones who make comments on online car ads but never make a bid - would always question anyone selling a Twinspark as to when they had last changed the belt, and state that it should now be done every 30,000km or 3 years - whichever came first - according to the factory.

I suspect that someone - perhaps the same agency who used to service this car - is attempting to drum up work. For the factory to halve their own cambelt life seems absurd to me, but, I have opened the cover a few times in the past years just to take a good look at the belt to make sure it was not aging prematurely. It looked worn but healthy to me, but two weeks ago I decided to replace it as several of my cars are about to need work and this was the easiest one to undertake.

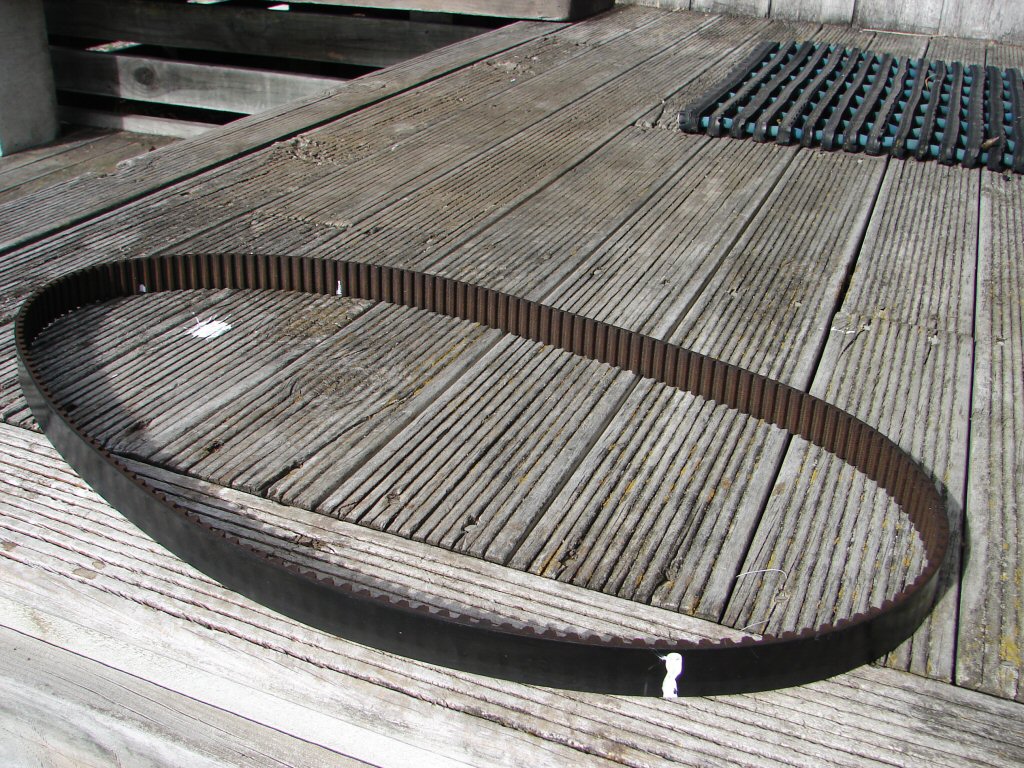

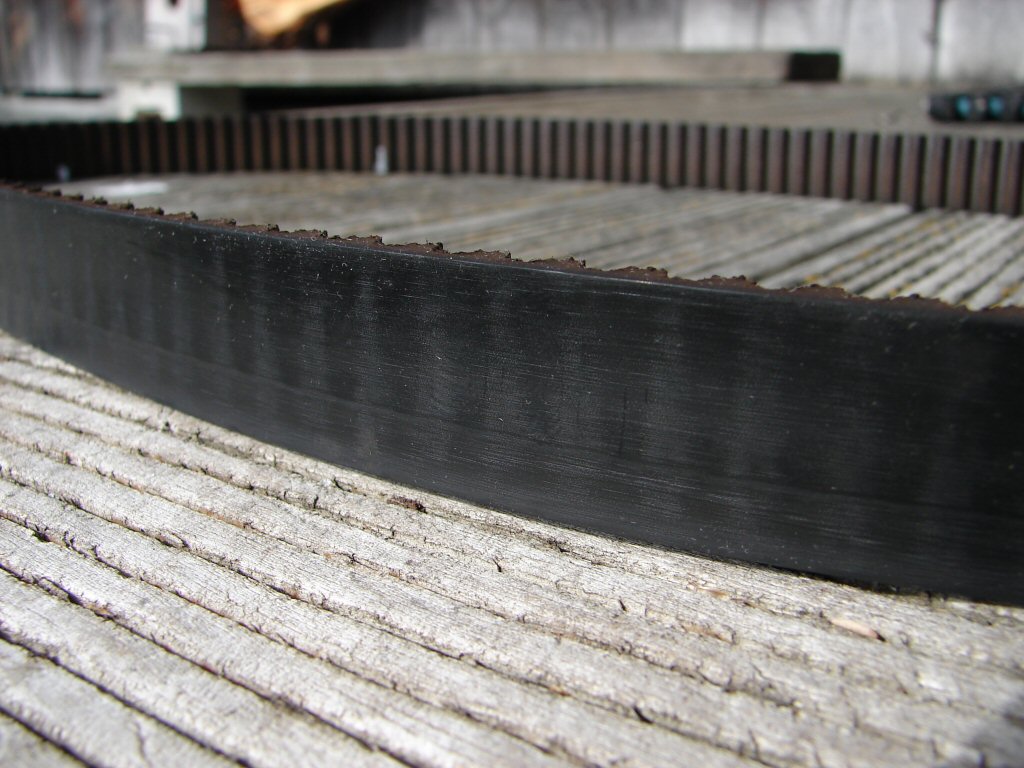

Here is the old belt that came out last week.

Having inspected it carefully I can say that the wear is very uniform over the entire belt as far as the teeth are concerned, and the reverse side well polished by pulleys but again, no signs of any trauma or beginnings of anything terminal.

Ignore the roughly applied white marks which are my standard method of recording everything as it stands before disassembly..

I see a well worn belt which I figure would have made the 60,000km with ease, but as this is the first Alfa belt I have gone nearly full term with I needed to prove it for myself.

We have a temperate climate in NZ, so the belt has not been exposed to extreme hot nor cold, although it was mainly used for commuting for the last 5 years so has seen its share of city traffic use.

I can say that I am not averse to using high revs when when the feeling takes me, but being a rider of old motorcycles I am in the habit of matching engine/gearbox revs when changing down - I like being smooth - so I avoid the inherent stress of dumping clutches up or down, and I get great mileages from my vehicles. My Volvos enjoy 160,000km cambelt life so I consider the Alfa TS to be a tad on the "brittle" side and I treat it accordingly.

Despite those considerations, I am of the opinion that the rumoured '30,000km/3 year' belt life expectancy warnings are unfounded, and will be leaving the new belt for the full 60,000 this time around. I will keep an eye on it however as I do not consider all belts to be equal, and this one was manufactured in Romania so is an unknown quantity thus far.

Love the way my Alfa drives.!

Cheers all.