2015 - I bought an unfinished race car project - the builder was known to me, but he had died before completing his project. The car had changed hands several times and ended up with a man who was keen to see it finished, but lacked the enthusiasm to do it. He thought I might as I had several of the same type of car.

1975 Morris Marina Coupe - by Leyland, Australia.

Initially I split the deal with a friend who was to fit a Rover V8 into a Marina Coupe, and this body was much better than what he had. I kept the engine and gearbox for another project I had.

Several years later, neither of us had made any progress, and it was made known that he was going to quit the body. I felt that perhaps I should grab it back and reunite it with its original powerplant, seeing as I had not used it as I had planned. So that is what happened.

End of September 2017 we got together, drank some beer, dropped the car onto its wheels and surveyed proceedings. It was so good, and yet it was so basic that mountains of work would be needed to put it on the road. But that was what I planned to do.

Money changed hands again, and two days later I called around to transport the car to my place. He was at work, so I manhandled it myself after correcting a major steering alignment issue. Fortunately my hired trailer had a winch..

The transition journey went very well. The bodyshell is very light and did not place much stress on either trailer or tow car. In quick time I was offloading in my driveway.

I climbed inside it at this point, and releasing the handbrake, allowed gravity to do its thing. The trailer deck was supported otherwise it would have flipped up as the rear wheels left the ramps and gouged the underside of the body. Not having that.!

A modest amount of pushing and pulling saw the car placed in front of my shed amongst a number of other Marinas. It must feel right at home...

It was a bit of a no-brainer to decide that the best course of action would be to fit the original engine and driveline which had already been removed from this car. In the time that the engine had been in my care I had discovered several local engine specialists who had been involved in the rebuild process, and they had been able to give me the information I needed to complete it's assembly. While everything had been attended to I am still unsure how radical the camshaft profile may prove to be, and whether the non favoured 3 into 1 exhaust manifold will perform as well as an LCB type, but it certainly will not sound like your average MGB, which is what the engine is from.

Engine is complete other than its external plumbing.

Due to necessary work on several other cars, this one has sat undisturbed for some time. I had to decide which direction to take in building it as a Leyland or a Morris. This is my only experience with a Leyland Australian version, although I believe the body shell to be much the same as the UK versions. Fact of the matter is, I have numerous spares for UK models, and none for this, and the engine and gearbox that came with it are UK type as well.

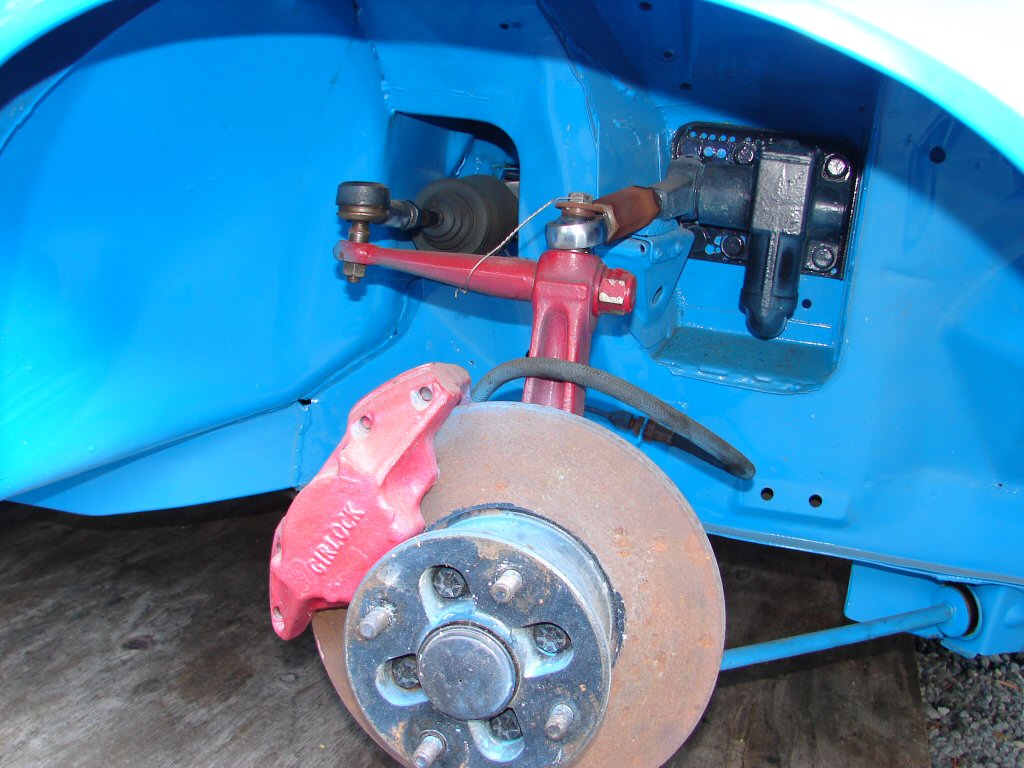

Investigating some mods which have been made to the suspension revealed that the car would not qualify for a warrant of fitness unless some engineering and compliance certificates could be obtained, but also, the suspension was all from a 6 cylinder model, and was hideously heavy duty and just plain heavy. My approach has always been to use softer suspension but to beef up the shock absorbing, thus increasing the compliance over rough surfaces, of which we have many. The sheer weight of the fitted suspension would be a huge penalty in unsprung weight, so it would have to go.

Stripping begins.

Besides making the shock absorber arms adjustable for camber tuning, the swivel joints on the top of the uprights have been cut off and a rose joint attached. It all looked a tad Heath Robinson to me, even if this car had only been intended for the race track. The upright is of greater cross section and turned 90 degrees compared to a UK version. Torsion bars are a massive 27mm, compared to the 19mm standard and 21mm heavy duty options for Morris models.

All braking parts were removed as a split system setup from a Mk3 Marina will be used with different master cylinder and lines, plus a device on the firewall which warns of fluid pressure loss at either end.

Having spent considerable years since its inception in storage, the body shell has gathered a few areas of surface rust, so that will all be dealt to before any of the new suspension gets fitted.

The Coupe was built as a LHD, with corresponding steering rack and dashboard. The Mk1 dash is gone and a Mk3 type will go back in, with its more modern layout and gauges. The rack has not been removed yet for no real reason other than I have not gotten to it. I now need to paint a panel to blank the LHD pedal box, and have had some paint made up to match this blue in both rattle-can and spray forms, so I can attack small areas as I get to them.

The rear axle fitted to the '6' featured twin trailing arms which formed a parallel mounting to resist the axle twisting under acceleration. Rather than weld brackets to the new Mk3 axle, I am hoping to utilise the anti swaybar as fitted to Mk3's because it seems the mounting point the trailing arms used is in the same position as those used for the ASB. I will need to modify the chassis as it has a blind hole from the outside with a captive thread inside the chassis, whereas I need a hole from the inner side heading out. I hope to drill through the inner wall of the chassis so the original ASB bolt can still use the internal captive thread. Here's hoping.

This is progress to 21st December 2020.