1952 Austin A40 Devon - An Act of Sheer Perversity.

Occupancy of this slumlord apartment by more than 59 persons is not unusual.

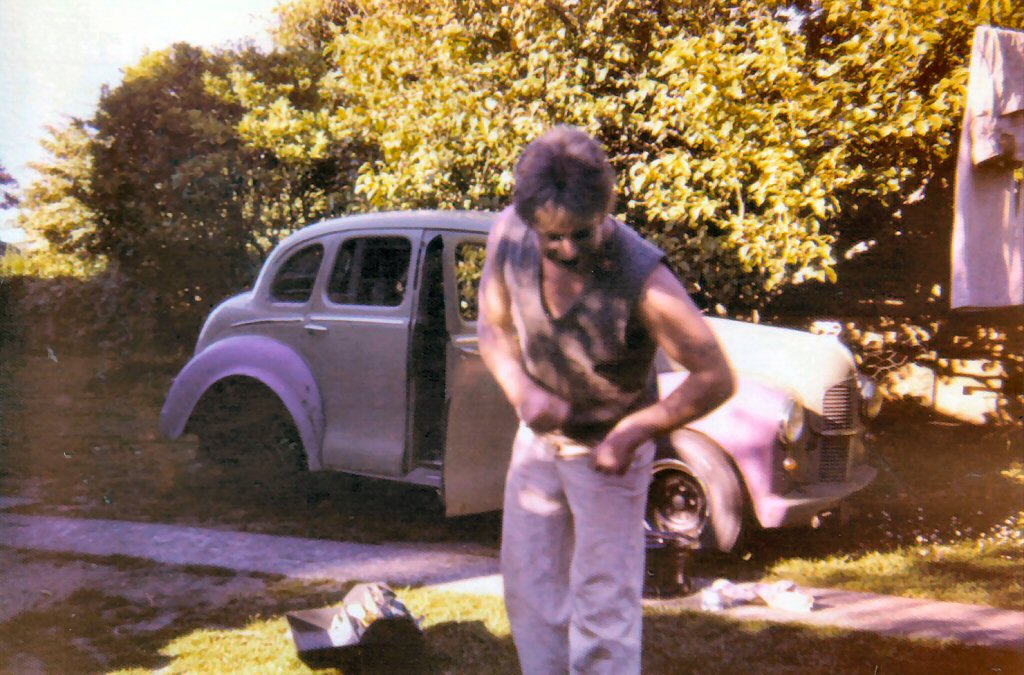

1971

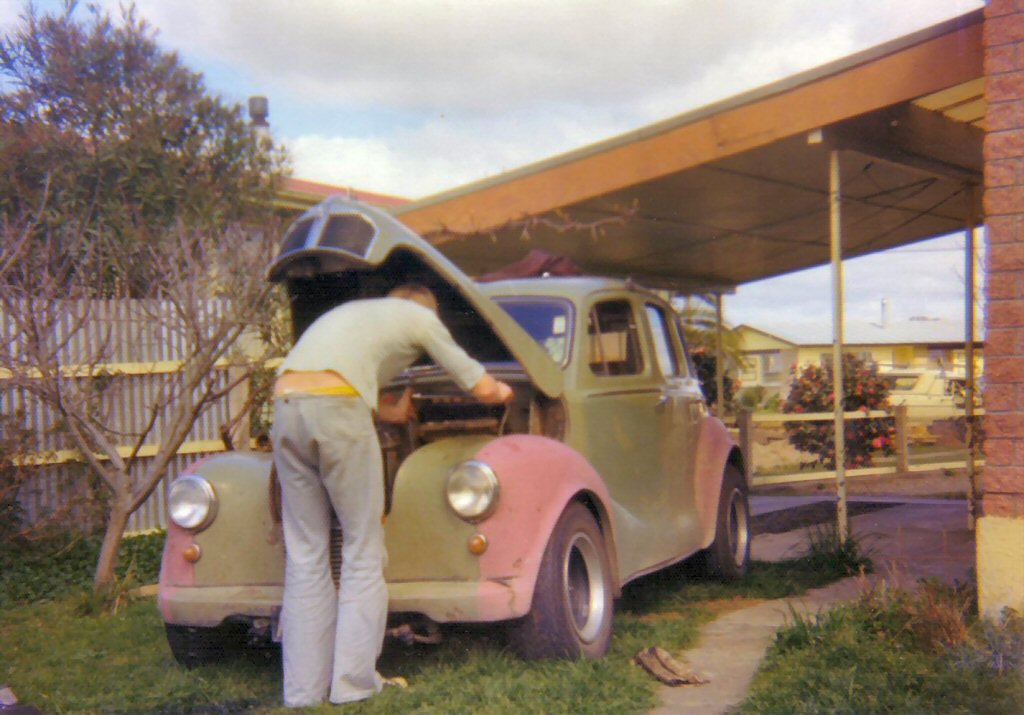

I lived in a slumlord apartment whose occupancy varied from 4 to 59 depending on the night, but which featured a large gravel carpark. It had featured a lawn and rose garden, but we discovered that gravel needed less mowing. This provided a large and useful - if somewhat alfresco - working space for the vehicles which resided. Rather fortunate considering how frequently they broke down, but budding mechanics don't always get it right. The carpark assumed the visual aura of a wreckers yard, as we all wired, hammered and spannered our way into meaningful skills - or gave up in the process.

The carpark assumed the visual aura of a wreckers yard.

Yes - those feet are in use..

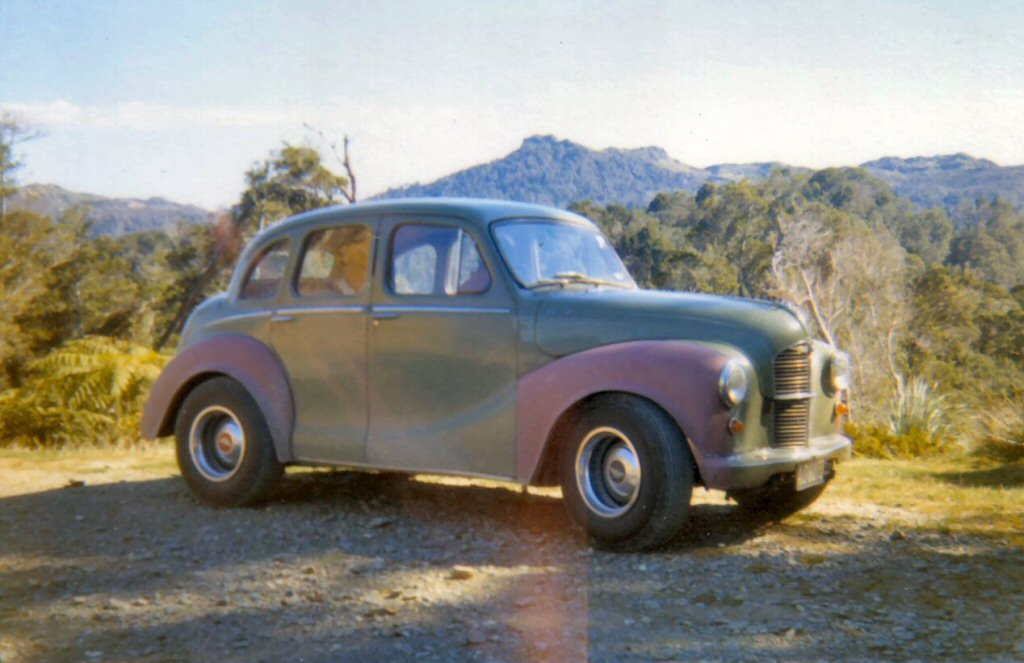

My vehicle of the period, was an Austin A40 Devon, made in England by stout but retarded individuals, and exported to New Zealand in the heady days of 1952. My first car had been a 1955 MkI Zephyr, which basically finished its life with me in a rather deep gutter in Christchurch one forgettable night in 1970. The Austin was all I could afford as a replacement, and although it was pretty straight, I felt somewhat reduced in stature as I gallantly fought the column change whilst prodding the pedals vigorously in order to elicit some signs of life from the fearsome 1200cc's of English majesty. What price the Empire eh?

Get 'em while they're hot..

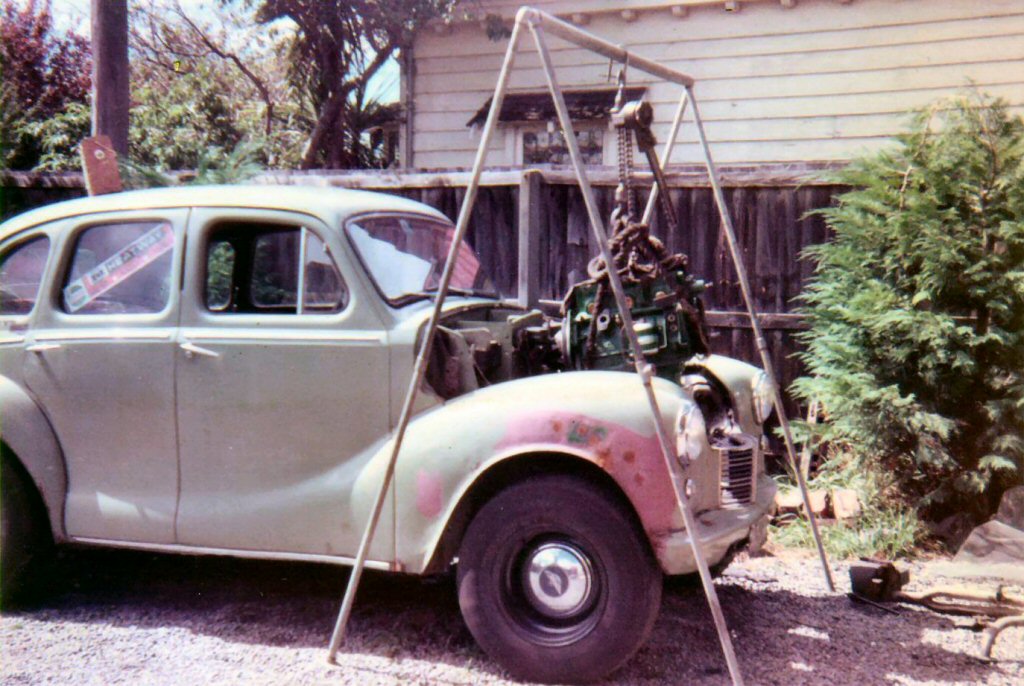

Having thrashed the old 'Ashcan' into submission one early morning on the way back from Kaikoura, we towed it back to the flat and there it languished while I mustered enough bravado to start pulling many of its bits off. The engine was stripped revealing a holed piston, but there were other misdemeanours which meant serious expense was to be necessary. I actually purchased a brand new cylinder head for it, and via some tenuous friendships, managed to get the head 'ported' and 'polished', quite an elaborate process in those days - especially considering the choice of vehicle.

Pulling many of it's bits off..

Other friends knew people who knew people, and when the finances could finally support it, the motor was rebored and new pistons fitted. It used to take an entire day to organise the borrowing of such a tool as a 'ring compressor' in order to get the pistons into those shiny bores - but it was all a learning process.

Ported and polished..

The final touches were a 'long centre branch' exhaust manifold, and a 28/36 downdraft carb, which entailed having the inlet manifold modified quite severely. I can't remember which modified camshaft was used, I am still rather amazed at how ambitious the project was considering my relatively infant skills in the art.

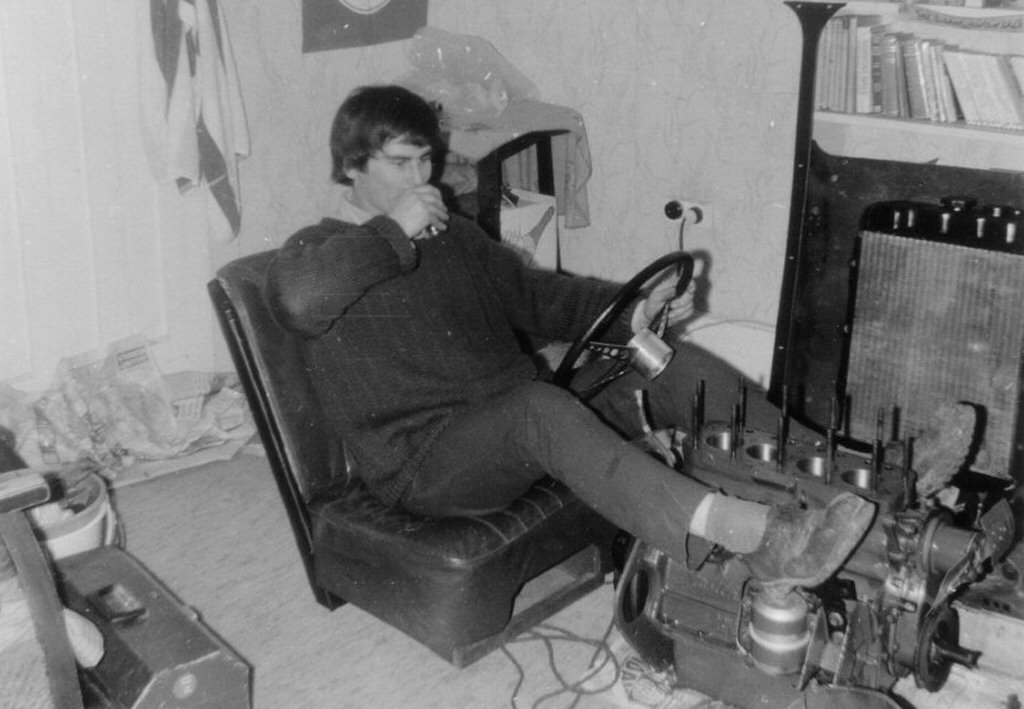

A large part of the fun generated by this procedure, was to do with the fact that no sane person would ever bother undergoing such an exercise. It was the adversity itself which fuelled my interest. Much of the work was undertaken in the bedroom, being the only part of the flat to which one had exclusive rights. During late night drinking sessions flatmates would try each others projects out for size.

"M H Turkey" tries it for size..

The machine finally ran without much trouble, and in retrospect, performed satisfactorily. We were seldom off the road providing we had money for fuel, and 800 mile weekends were quite normal. I fitted a rev counter, and imposed a limit of 6000rpm for safeties sake, having read that dreadful things might happen to the crankshaft if I exceeded this figure. Often we made trips involving 2 or 3 cars, but invariably the idea was to put as many miles between yourself and home/work as was possible in the time allowed.

About this time I met Chris. He was a motor reconditioner of some repute, and as such was held in great esteem. Added to this was his choice of wheels - a modified 6/80 Wolseley! This was about as insane as an A40, so we became friends.

I set about finding some 'Fat Feet' for it. Scored some 7" wide 14" rims at a truck spares place, and had them welded to my original centres, which despite being from 16" wheels, were a perfect fit. The only tyres I could find, let alone afford, were Dunlop SP radials, of a profile so great that they had the appearance of having fallen off a DC3. A friend who possessed some panelbeating skills was enlisted to reshape the mudguards and add a slight flare to cover the tyres.

Tyres had the appearance of having fallen off a DC3..

This was done by tacking a piece of steel around the arch, and filling the outer side with lead. The result was enormously strong, despite its thin edge - as my Father discovered once when he backed into it, pushing it sideways across the drive with the loss of some primer from the Austin, and serious damage to his Singer Vogue.

Watch them lead flares..

One night as Chris and I were screaming down Memorial Ave, I shouted "you watch how the power drops off at 6000" as we howled along in third gear, eyes glued to the rev counter. The magic figure arrived, and with it a tremendous bang, followed by a dreadful clattering as I killed the engine and coasted to a stop. Screeching with laughter we raised the bonnet to see what horrendous sight might be revealed. In the dark, we could see nothing at all, so Chris legged it to get the Wolseley and tow me home.

Couldn't wait to see what had happened..

I absolutely couldn't wait to see what had happened inside the motor, and was frantically hauling bits off at first light. The crankshaft had broken between the rear main bearing and no4 big end, causing the no4 piston to suddenly develop a stroke of a length the block couldn't accomodate, whacking bits left right and centre. We threw a lot of stuff away, and Chris machined some used bits from local wreckers and we were in business again. Haha.

Whacking bits left right and centre..

Astute fellow that he was, Chris actually owned a house up in Cambridge, with the added benefit of a huge workshop, in which he had amassed a variety of machines for reconditioning engines. When he returned there from Christchurch, we kept in touch, and he devised a plan for fitting a larger engine in the Austin. The idea was to get hold of an Austin 1800 'east/west' engine (cheap), plonk a sump on it and run it 'north/south'. To add to the general confusion, Chris had some pistons from a sidevalve V8 which he might be able to jam in to make the plot a tad more excitable. Word filtered down that Xmas (1972) would be the changeover date.

A house in Cambridge with a huge workshop..

Left Christchurch one early am for the trip to Picton and the Ferry, for the great engine changeover. Only made it 30 miles when there was a loud rattle from the engine dept, and a dramatic loss of oil pressure. Sent word home, and my Brother came to tow me back. The crankshaft had broken again, but this time near the centre main, so not quite as disastrous. With the sump off, we put the car on the hoist and ran a weld along both sides of the crankshaft web. The car ran ok, but I didn't like my chances for the 500 odd miles up to Cambridge. Phoned Chris, who agreed to meet me in Wellington just in case, and that evening I drove the car onto the 'Rangatira' at lyttelton for the overnight sailing to Wellington. As I departed up the ramp from the ship to the wharf at 7am in Wellington, there was a loud rattle from the motor.... Bugger!

Happily enough, Chris was on the wharf, and we threw a tow-rope on the Wolseley for the long haul. The steering felt strangely heavy as we charged along at 70mph, and it was quite a job keeping the plot together. Near Featherston we came belting around a corner, and here was a Traffic Officer waving us down, and ahead of him was a house crossing a bridge, using the entire road. I very nearly became a back seat passenger in the Wolseley.

Pushed the button anyway..

North of Taihape, I suddenly remembered the box brownie, and decided to record the event. I got a huge fright as I stuck it out the window, and all but through the front windscreen of an Alfa Romeo that appeared from nowhere. Recovering from the scare, I pushed the button anyway.

Somewhere along the Desert Road the rope broke. As I went to re-attach it around the front bumper brackets of my car, I discovered that Chris had accidentally wrapped it around the steering linkage that joined the steering box to the idler box - steering was much improved after this!

Brakes smoking, we finally pulled into Williams Street Cambridge, and the motor was out within hours. The new 1800 had a backing plate from a 1622 Morris Oxford, and a sump from a JU250 van. It all bolted up perfectly using the A40 starter, and the only mod required was to raise the front engine mounts half an inch so that the crankshaft pulley cleared the front crossmember. There was a 'Wade 121' camshaft, and the original 1800 SU carb and exhaust manifold, suitably bent to function

What a revelation! The motor was very strong, and propelled the relatively light A40 with a gusto hitherto unimagined. Only teething problem was the clutch release, which had a little further to travel as the 1800 clutch was a slimmer unit. We clocked up 500 miles before we could bear to pull it down and invent a solution. Apart from the limitations of brakes and handling, the car was tremendous fun. The exhilaration of ample horsepower was only paled by the glee of blowing off Chrysler Valiants as their owners jaws dropped at the sight of two idiots grinning like apes at 100mph plus in a pensioners shopping basket. Cowabungah!

The repowered Austang about to leave Cambridge heading for Christchurch..

On the trip back to Christchurch, I was powering up a long incline, when the car suddenly began to slow. I eased up, nudged it again and all appeared normal, but I began to detect a slight ticking noise. A phone call to Chris later, it was decided that a piston had probably 'nipped up', meaning a slight seizure. I did the only thing possible and ignored it.

After a period of saving money, I was able to buy a 45mm Dellorto carb, and a 'Berry & Chung' inlet manifold. I also bought a brand new MGB exhaust manifold and front pipe, which once again amazed me by bolting up without a single glitch - the twin headers negotiating the tiny space around motor and suspension as if designed for it. A terrific power increase was gained, and now with a superb exhaust note. I was chuffed! The biggest difference was the way in which the motor responded. With the old SU, the car would just keep winding up the revs, but now it reacted almost violently when you stamped on the gas. I never quite mastered the jetting of the accelerator pump, so I developed a technique of slower use of the pedal.

Fun.. fun.. fun..

Much hilarity and traffic-light mayhem later, I was dragging a 3 litre Vauxhall one night when a loud bang with smoke heralded another mechanical meltdown. I had enough momentum to both stay ahead of the Vauxhall, and coast to my flat, so honour was maintained. A piston had broken, fortunately the crown remained at the top of the bore, while the skirt stayed attached to the conrod. Chris sent down another piston, and I found an A70 diff head to raise the gearing and keep the revs down. In true Austin fashion, the A70 diff bolted straight in to the A40 housing, accepting axles and all. I later fitted an A90 diff in the same fashion.

Chris had been pondering the piston failure, and decided that there was a problem with the actual shape of the V8 pistons. They were not oval enough to withstand the expansion caused by localised heat in the BMC 1800 block because it had 'siamesed' bores. The front and rear pairs of bores were very close together, causing this situation. The answer was to find pistons which came from a similar style engine. Fortunately the solution was also cheap. Standard MkIII Zephyr pistons were now mostly surplus as motors were using oversizes, so plan B was hatched.

Late 1973 I moved to Cambridge, and shortly thereafter the new pistons were fitted - crown height machined down so they didn't smack the head, and the skirts shortened slightly. The compression ratio we estimated to be in the 11/1 vicinity, capacity just over 1900cc. The motor was very petrol conscious, and had to be stalled to prevent violent running on, or 'dieselling' as Chris termed it. The Wade cam was discarded in favour of a milder BMC 731, so as to avoid the occasional bent valve when I was getting too excitable.

One morning on my way to work along the Cambridge-Hamilton road, I rounded a bend to find a large truck lumbering along at much less than my 85mph. I began slowing, and took a look past to see if I could overtake while I still had plenty speed. A car was approaching, so I braked harder, but it became apparent that the truck was slower than I had thought, and I would probably have to rush past and risk offending the oncoming driver. I took a second look, but the car was too close, and there was nowhere to go. I was now actually standing on the brake, with my bum off the seat, and aiming for the non-existant gap between the truck and the car. Just as the car whizzed past, I pulled in under the back of the truck, folding his mudflap to the side, and within an inch of his tyre. We were now doing the same speed, and as he gradually began to pull away, I blessed the driver for not reacting by putting his brakes on! I arrived at work slightly gray, and determined to finally fit the Wolseley 6/110 front suspension and disc brakes that I had brought with me from Christchurch.

On standard A40 suspension..

Believe it or not Veronica, they bolted straight on! 1952 A40 to 1968 6/110, and the upper and lower pivots were identical. Thank the stars for good old British over-engineering. I also fitted the shock absorbers from the Wolseley, which resulted in a large amount of negative camber, resembling some sort of speedway device. I had found some A90 front springs which I took a total punt on, and had them shortened by half an inch. They fitted perfectly, and with a small amount of hacking the inner mudguard panel, I was able to find clearance for the larger shock absorbers. The back end was then lowered by use of blocks and longer U-bolts, and a Hamilton chassis plant cleverly took the set out of the top suspension arms by placing chains around them, then jacking the lower ones. We settled for 1 degree negative camber, and to my delight I found that the car now steered like a mini, very quick in the cornering, and no body-roll at all.

Wolseley 6/110 come A90 lowered suspension..

Probably due to the rather high compression, and the extra engine braking effect, I began to rip the teeth off third gears when slowing down. The huge chassis in the A40 only allowed the use of a very short gearbox, and I was out of enthusiasm for major changes, so I just kept finding spare units. I fitted 5 of them, and only paid $5 for one (in a weak moment), the others were all free.

The engine was now proving to be very reliable, and the only disasters were the loss of a piston due to a small bolt falling out of the air filter and being consumed and hammered into a piston, and a gudgeon pin which broke into three pieces. I actually drove 250 miles with it broken before searching for the source of the rattle. Ignorance is bliss!

Head going back on after another piston replacement..

The final manoeuvre was the fitting of a complete Wolseley 6/110 rear axle assembly. I was tired of having different stud patterns front and rear, and the original A40 wheel centres were beginning to crack up. Unfortunately, the rear end was much wider, and I had to offset the rear wheel centres to compensate, so I still had a spare wheel that only fitted one end of the car. I forget which end that was! The final gearing was now 3.6/1, and the handbrake was truly magnificent.

The final manoeuvre..

A flatmate in Hamilton painted a portrait of Marilyn Monroe on the upright boot of the car. It may have been a bad omen, as the car began to go downhill after that. I estimate that I covered several hundred thousand miles in it, mostly at highly illegal speeds, and the traffic fines were becoming a difficult financial hurdle. While 100mph came up fairly quick, having the aerodynamics of a brick outhouse was a power sapping affair. Best speed ever was 120mph while overtaking a modified Hillman on the Desert Road - things were getting fairly agitated at that rate of knots.

Apart from the rear of the car smacking a dirt bank while sliding down a gravel road, which only resulted in grass under the chrome trim, I never had an accident or collision in the entire time I owned the car.

'Burgly' aka 'The Austang' was finally sold by my Brother after I had departed for Australia. I once read an ad in the paper in the 80's that sounded familiar, and it turned out to be the old A40. It was in Springfield, had a different body, motor and gearbox. I guess it still had the soul.

After years of owning modern vehicles, I thought I had probably lost the enthusiasm for modifying the type of cars that nobody else would bother with. Then I got hold of a Morris Marina....