October 2022

1974 Triumph T150 Trident 750

Out of the blue a chap phoned. He was looking at buying a T150 from a friend, and wondered if I would help him wake it after an 18 year snooze. Seemed he had bumped into a friend of mine and discovered that triples were my favourite flavour. We spoke for a bit, and I told him to send me some pics of the bike so I could give him an idea of its value.

I also told him I was preparing a Rocket 3 for sale, so he thought he would like to see that too.

Some pics came my way, and it looked like a tidy complete bike. Turned out that it had undergone a complete restoration while in the ownership of his friend, but that it got laid up due to lack of use. I thought it was a suitable case for treatment.

He called in the next day while I was running the Rocket, and that got his juices flowing. There were some more photos of the bike, but when he told me what his friend wanted for it I told him that he really needed to buy the T150. It was just too good an opportunity to miss out on, and obviously mates rates.

After a days cleaning he brought it round for sorting.

Lawdy.!

Bikes seldom come into my shed looking this good.

But I won't let that stop me making a mess of it.

Hydraulics were totally seized, and apparently there were a number of top end oil leaks that may have prompted the layup.

In no time there were two triples in bits in my shed.

Rob wanted some different handlebars put on it, so I took the opportunity of removing the existing ones, along with the clagged brake master cylinder, and this would make changing the fork oil somewhat easier. The brake fluid reservoir contained the usual tomato soup that fluid turns into after the occasional decade. Does not bode well for the caliper either.

I had removed an empty battery and put my full one into the bike to see what electrics may need sorting. The left indicators did not work, and there was no front brake light switch fitted. As the numberplate on the bike had lapsed, there would be a compliance test required to get a new one. A front brake light switch would be a necessity, but the original Lucas item was neither available nor much use when it was. I decided I would fabricate one in a similar fashion to a T160 I had once worked on that had been in the same boat.

The headlight came apart in order to faultfind the indicator issues, which turned out to be a fault in the left side switch unit. I had to reform one of the moving contacts within it to effect a decent contact pressure, which gave the needed result. The idiot light for the flashers was rather dim which was a puzzle, until I took the tiny lamp out to find that it was 24 volt. The amount of time one can spend riding with an indicator flashing vainly while waiting for a suitable junction means you really need a bright idiot light. Otherwise one is not a bright idiot.

I decided to start at the sharp end first, so the wheel came out and the forks got drained. The oil was clean, but the last of it was a tad sludgy. I gave the sliders a good flush before adding new oil and buttoning it up.

The best thing about ripping everything off is that you can now put everything exactly where you can see it needs to go. Those cables do not like sharp bends.

Forks reassembled, the wheel went back in. Only applying some fluid pressure to the caliper would prove whether it was in a healthy state or otherwise.

The front brake master cylinder was too far gone to repair - a command decision - and I had no wish to spend a few hours confirming that.

Just getting the bits apart so some can be reused is trouble enough, though the hot water treatment has never failed.

That led to some cleaning and painting of the alloy housing, prior to beginning the process of inventing a brake light switch.

The master cylinder came together with its new stainless cylinder and fresh paint, plus the trickery to operate the relay for the brake light all in place.

I had to run a new single wire from the housing back to the headlight, so I painted it grey to look like it belonged there.

This brought things to a standstill due to awaiting parts, so I stripped some carbs and set about ensuring that all 3 carbs contained the same parts, configured in the same way.

They didn't, but now they do. One main jet was a different size, possibly in response to the centre piston having melted in past history I had been told.

A courier dropped off an odd parcel.

No prizes for guessing..

Excellent timing. This allowed me to resurrect the braking system, which would in turn allow the wiring of the brake light switch and it's relay in the headlight shell.

So that happened next.

Of course, I was eager to test the braking system to see if the caliper would pass muster. The first good squeeze of brake left me with a seized front wheel, so that was a fail. It is also why the caliper is missing in the above photo.

I was going to farm it out, but when I found that my usual parts supplier had a seal kit, and I remembered how much I had been gouged for the last calipers I had rebuilt, I stripped it down myself.

The rust that was responsible for the seizure was self-evident, so I cleaned it all up while awaiting the seal kit.

Those parts duly arrived, and the whole plot went together happily and got refitted to the bike, looking somewhat cleaner than it had.

After the pipework was reinstated it bled up without trouble and we had a functioning front brake.

Moving rearward, the next item needing attention was the right side oil cooler reflector, which was in danger of leaving town as its glue had given up.

This received the standard lockwire approach, where the wire passes through the inside of the cooler endplate and gets set into a groove cut in the rubber mount, so the unit can never go missing in action.

Next came the leaking rocker boxes. Some well-glued copper gaskets had failed to achieve a result, so I would hope for a better outcome with my preferred aluminium type.

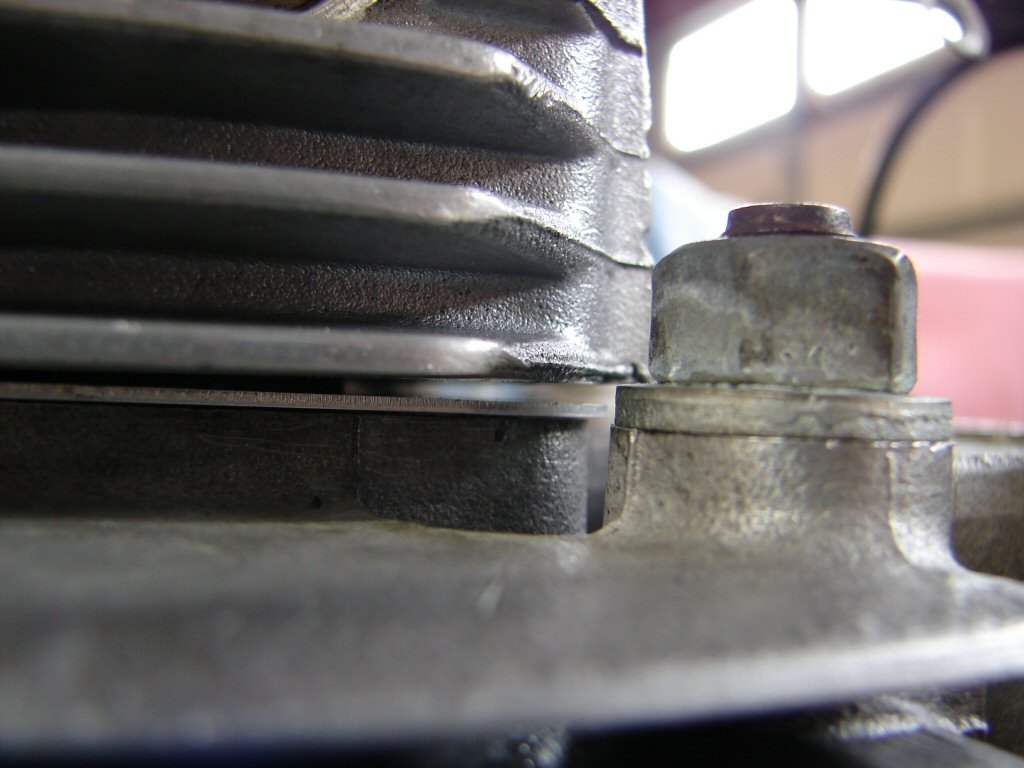

Some care is taken to make sure there is enough crush applied to the pushrod tube seals once everything is tightened down. Something more than .040" is ideal, and we can see that being checked before the pushrods go in.

A thin coating of silicone sealant is applied to the aliminium gasket after this, so that any minor imperfections in the mating surfaces should not let the side down.

The rocker box covers had suffered from overtightening syndrome in the past, and despite having been welded up, were hardly flat. They received a light face up, and a slightly more generous coating of sealant once the valve clearances had been sorted.

The carbs were refitted about now, so the engine dept was hopefully complete apart from draining and replacing all the oil and the filter. The gearbox oil also got treated to a fresh batch of fully synthetic, and the engine got kicked over a few times to see the oil light go out.

During that process it became obvious that the kickstart cotter pin was past its best by date, so it got replaced, along with gearlever and kickstart rubbers. Attention to detail is very necessary if the bike is going to enjoy the full benefit of getting things right.

Continuing rearward, the back wheel needed to come out so that the brake drum and linings could be measured up for the brake declaration.

With the wheel back in and everything adjusted we were starting to look like a rather sorted enterprise. Good time to record progress.

The bike ran perfectly well after a bit of tinkering with the carbs, but was not a happy starter. It preferred to light up with zero throttle, and could then be revved a little more without argument, but the process was a bit counter-intuitive and often made starting a longer procedure than it should have been.

Everything worked well enough to begin the compliance process though, so I rode it in to the peeps who do that and we shuffled bits of paper. As is more often encountered than not, there was an immediate problem. Although the expired plate existed in the system, the frame number did not. The engine number was quoted and correct, but the frame numbers absence rang some alarm bells for the form fillers, especially when attempts to actually read the frame number through its thick coating of paint began to look as though it was entirely wrong for the bike.

They sent me away with instructions to remove the paint from the frame so it could be read, although I had already managed to do so. The plot thickened. The frame was nicely factory numbered, but was post-production and dated February 1976, a bit late for a T150. I figured that the bike had suffered a prang and been rebuilt into a new frame. This produced a frenzy of pondering which eventuated in their decision that a repair certificate would now be needed.

Sheesh.!

How come they always go for the expensive option. I immediately argued the point. This frame has not been in an accident, it is a replacement frame, so why a repair cert.?

Fortunately the testing chap was a friend of mine and T140 owner, and saw the logic. We would however now have to obtain a certificate of authenticity from the VCC and apply for permission to use 'alternative documentation', which is LTA speak for needing to enter a number into the system which they had originally bungled.

It would now also involve long periods of nothing happening and nothing you can do about it. This system is plagued with problems which they always make ours, and demand more money to resolve.

Literally months passed, so the owner took the bike home while we did our time.

Finally all paperwork was in hand to send to the LTA, and permission was subsequently granted for the compliance process to be completed, although many phone calls, emails and cursing were brought into play.

Sure looked purty though...

I guess the process all up took four months or longer, as xmas intervened, but finally everything was in order to complete the compliance test. The owner phoned to see if I would take it in, but as they already had all the paperwork I figured he might as well ride it in himself.

During the interim, my testing officer friend had retired, and they sprang the final insult and demanded a repair cert.!

The owner did not feel qualified to argue the toss, and was so tired of the whole fiasco that he agreed. Two hours and $1300 later he was allowed to put a new plate on it, so I truly wish him the best ever experiences riding this lovely bike.

He has sure earned it.

I view these entire 'compliance' procedures as borderline criminal, as well as the ACC levy for every bike you register rather than the one you are riding, and have decided to flout the idiot 'rules' in future.

I do not comply.!