September 2022

1971 BSA Rocket 3 750

Allan's first Rocket 3 MkII turned out to be one I had seen at Pukekohe raceway during a classic meet. This was in the mid 80's, and it appeared to have been recently restored. Allan bought the bike unregistered in 1998.

By the time I met Allan he had rectified a few of the non-standard items that previous rebuilders had used. The fuel tank was a flip-top A65 tank, which had required moving the tank mounting bracket on the top frame tube, so he had that ground off and returned to its correct location. In between my seeing the bike and Allan buying it, a set of 30mm Amals had been fitted, which made things around the fuel tap area rather congested, as the 30's are taller than the original. They had been mated up to the adaptor and airfilter neatly though, so they stayed. Another fuel tank and side covers had been acquired, so the bike now looked quite different to its first incarnation, and a lot more original thanks to the chrome tank.

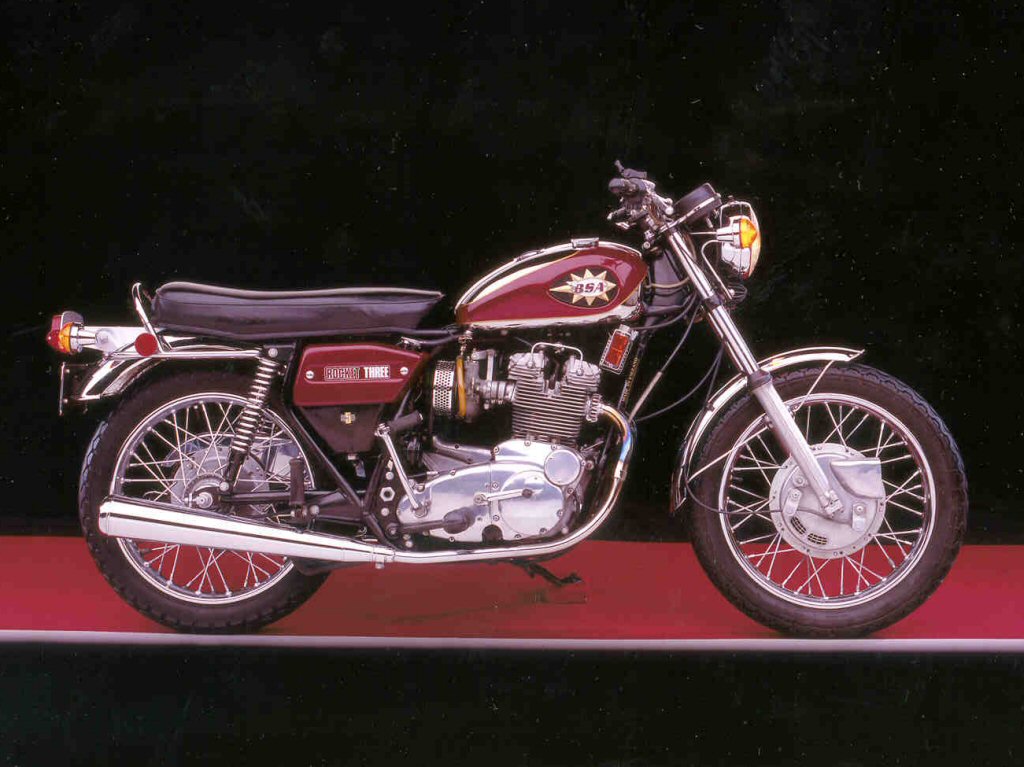

Commendably, it now looked very much like this California BSA club members bikes concours pic.

The bike was used infrequently, as it still had no official plate, and masqueraded as any one of a number of Rocket 3's depending on which numberplate was currently legal.

While it started and ran nicely, it had a slipping clutch when hurried, various oil leaks from the engine and front forks, a non-functioning speedo and other issues including a rather borderline front brake.

It was time to attend to all of the above, and whatever else might be necessary in order to comply it and obtain a New Zealand plate.

Bits started coming off it within hours of arriving in my shed.

I decided to work from front to rear, so the cracked front tyre, leaking fork seals and new fork oil would be first up.

A new set of brake shoes.

The original Dunlop TT100 had been made in Great Britain. I'm thinking that would have been at least 30 years ago, which might explain the cracks in the sidewalls. Presumably the inner tube would be the same age.

A Bridgestone with a modern profile was wrapped around a new inner tube, and mated up to the new brakes.

Next the fork sliders came off, and with some difficulty the old steel-backed seals were convinced to leave. The new ones were fitted with the help of a nifty tool a friend had made up. A nylon drift is slid up the fork stanchion, then the seal and slider, so the slider can be used as a slide hammer against the drift. Worked a treat, as the seal has to remain parallel to the stanchion.

With new 20w fork oil inside, the whole front end was restored and brakes adjusted. It soon became obvious that the front brake light switch had been disconnected because it stayed on permanently, so I pulled the cable out, stripped the inline brake switch, and added a couple of thin rubber pads in addition to the original which had become rather spongey.

Normal transmission was resumed. As the bike will need to be complied, absolutely everything has to work in the manner it was intended. A brake declaration must also be furnished, so the new brake shoe lining thickness and the diameter of the drum were recorded - with photographic evidence - to assist with completing that stage later.

Rocker boxes came off next, to reveal broken up gaskets which would have been the major source of the top end leaks.

Interesting to find that lash caps have been fitted on the valve stems. I had not come across them in practice, but suddenly two bikes in a row have had them fitted.

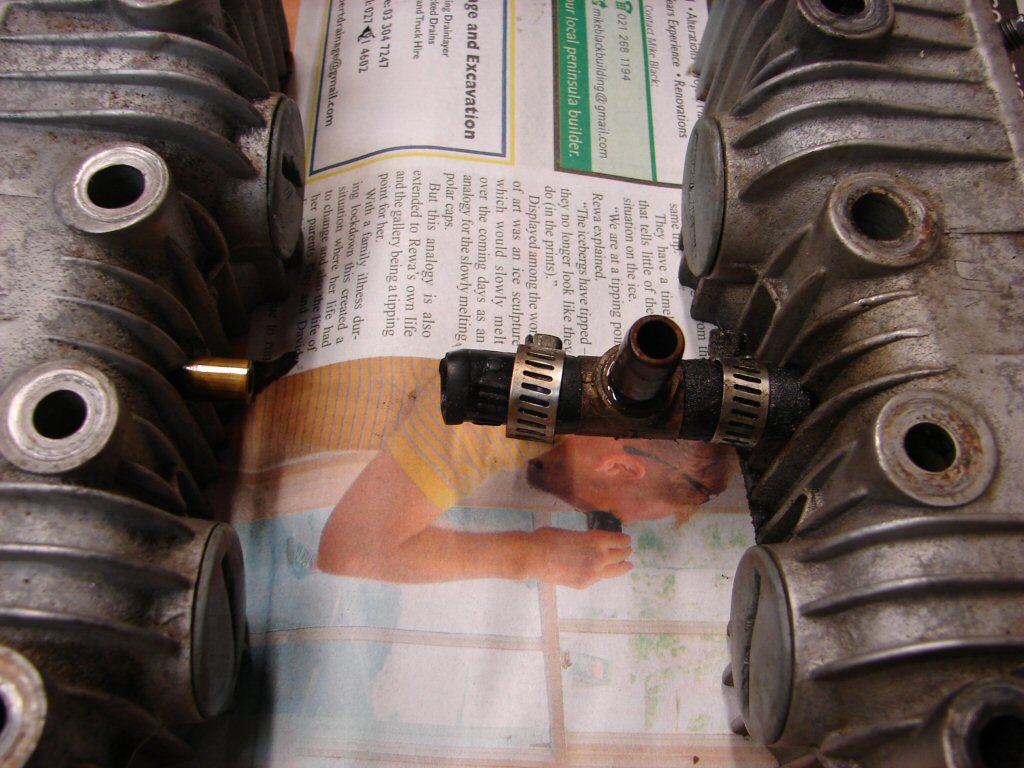

For no apparent reason, the rocker boxes have been modified to share an extra breather, and the usual crankcase to airfilter breather has been routed along the rear mudguard to exit by the numberplate, a la twins.

I began to find breather hoses everywhere, so I removed the entire system. This is a most amazing solution to ever be found looking for a problem. This bike would normally have featured a total of two hoses.

If they had thought for a bit, the length of the new exit arrangement is about 1 metre long, as opposed to the factory setup which is about 8 inches, so any fumes will have a much more difficult job making an exit.

I left the rear exit pipe along the mudguard and its connection to the crankcase. The rest got ditched other than the original arrangement of one hose from the primary to the top of the oil tank.

That certainly created a lot more space beneath the fuel tank for things like wiring and spark plug leads.

While working with the breather system I had to remove the right sidecover. I was most pleased to find that some astute person has vinned this bike in NZ. Presumably the plate had since lapsed, as none came with the bike.

This will make the compliance process a lot easier than it otherwise would have been.

Having fitted new alloy rocker box base gaskets, and adjusted the pushrod tube packers to give the correct seal crush, the cylinder head got tightened down, and the oil cooler refitted. It is so close to the exhaust rocker box that it must be removed to work on same.

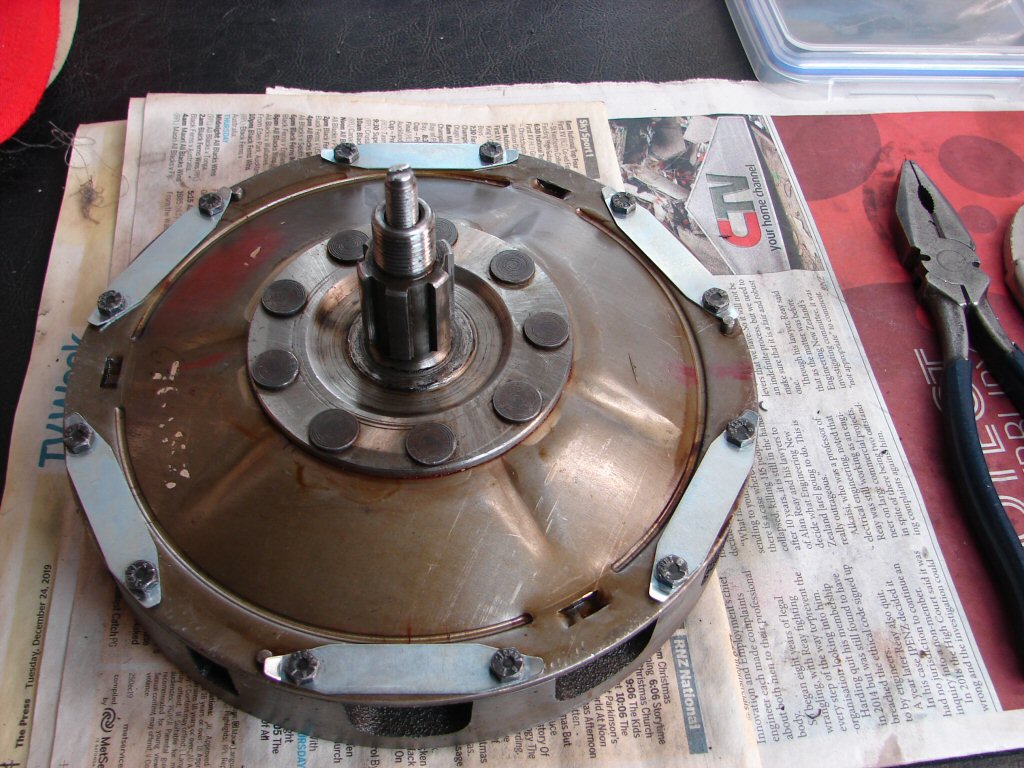

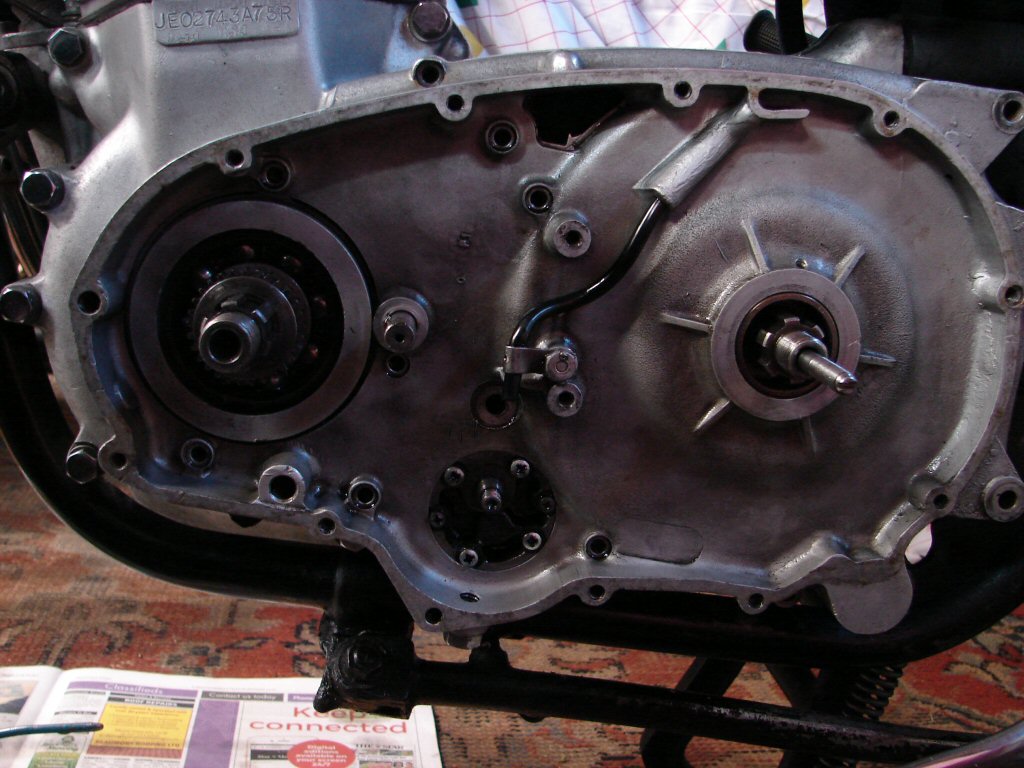

That completes the top end work other than the necessary retighten after first runs, so now the primary would come apart to replace the clutch plate.

Oh boy.

One of the first discoveries inside the primary chain case was this destroyed thrust washer, which has absolutely no excuse for even being here. It would once have resided on the opposite side of the cush drive spider, but as the entire assembly is drawn to the outside of the case by the clutch release mechanism, this bronze thrust is usually thrown away. Instead they fitted it between a radial roller thrust bearing and its mating running surface. The radial bearing was toast, and it can be seen how much it had worn its way into the bronze washer in the process.

How anyone could ever have thought to put these things together is beyond me.

They had then compounded their mistake by fitting the oil seal into the cush drive retaining nut the wrong way round, so I figure we are going to find a clutch full of oil.

And indeed we have. Plenty of oil both inside and out, so that explains the slipping clutch at least.

New clutch plate awaits in the background.

Clutch stripped, cleaned, new plate fitted, reassembled and bolted up.

Just waiting to have the locking tabs folded over so nothing comes apart in action.

Clutch now installed in its housing and the inner primary case fitted, having had a new oil seal where the drive goes through to the clutch shaft. I also fit an O ring behind the spline on the clutch shaft, so no oil can track through between the splines.

I did not take photos of the primary chain going back in, but I did fit the oil seal in the nut the correct way around, and replaced the outer cover gasket for good measure.

The radial bearing got replaced, but its thrust face survived without damage which was a blessing.

The additional thickness of the extra thrust washer would have forced the primary chain to run badly out of alignment, but checking it all I could not detect and signs of impending doom. A good thing the bike had done so few miles. Not sure how many in fact, as the speedo still reads the same mileage as it did on purchase in 1998.!

So the primary all got buttoned up and refilled with oil.

Because it is an unpleasant job, I decided to pull the rear wheel out and do the brake measurements, just to have it out of the way. All looked fine, and I adjusted the rear chain and did the wheel aignment at the same time.

The rear brake lever also had an odd extra part fitted in front of the adjuster, so that went and the foot pedal got positioned properly, after which the brake was adjusted to where it felt best from a riding position, and the brake light switch adjusted accordingly.

We are making progress.

While at the rear of the bike I decided to sort out the odd mounting of the mufflers. When I uplifted the bike I had noticed that the right muffler was mounted much closer to the wheel, and higher than the left. I soon discovered that while the left muffler bracket was mounted outside the frame lug, the right was mounted on the inside.

Musing at this inconsistency, I spent quite some time straightening the sturdy brackets and remounting both on the outside of the frame, while also attending to their relative heights.

I persevered until I felt that nobody's eye would now be offended.

In rather short time I made a new discovery. The kickstart lever now made contact with the right muffler.

Aha.!

Now we know why it was mounted on the wrong side then.

About now I vaguely recalled Allan telling me that the muffler brackets were the wrong ones. I did not have a parts manual for this bike, so I searched online and soon found a free one to download.

Sure enough, the correct brackets for this model featured two bends, so the bracket initially curved inwards, then vertical again. The overall effect was that the muffler would end up about halfway between where it was before, and where it was now.

So I took it off and bent it. As you would...

When I refitted it, it seemed that the two mufflers were now exactly the same distance from the wheel, and the kickstart now cleared the muffler.

I shall quit while I'm ahead.

The speedo had not changed its mileage reading since the bike was purchased in 1998, so presumably it had a problem. I took the clock out of its mounting and checked that I could turn the drive easily. I could, and I could get a needle deflection if I gave it a quick twist. Promising.

I had tightened the cable at the drive end when the rear wheel was refitted, but it now seemed that the inner cable was slipping inside the clock drive. On the off chance I checked if I had any speedo cables on hand. I did. And it was exactly the same length as this one. Spooky.

I made sure that the cable was a firm fit in the clock by using a small strip of insulation tape to assist.

By rolling the rear wheel a dozen times on the main stand I managed to move the odometer enough to know it was working, so the next test ride should indicate some forward motion.

Taking photos outdoors gave me enough distance to gain an overall impression of the bike, and I noticed that the kickstart seemed a bit rearwards of normal.

The usual suspect is a cotter pin fitted from the front instead of the rear. Sure enough. Easy fix.

The seat was an enigma. While the majority of the vinyl was a very healthy original style, there were two nasty rips in the top. I would be loathe to lose the original look.

I conferred with an upholsterer of some repute, and he suggested a local operator who could 'weld' the vinyl well enough to make it waterproof. I headed directly to 'Fibrenew' to see what could be done.

The man was confident that he could make it 100% better, so I decided to adopt this approach. Unfortunately it would be a week or so before he could do the job, so we agreed that I would get the compliance done first and the repair later.

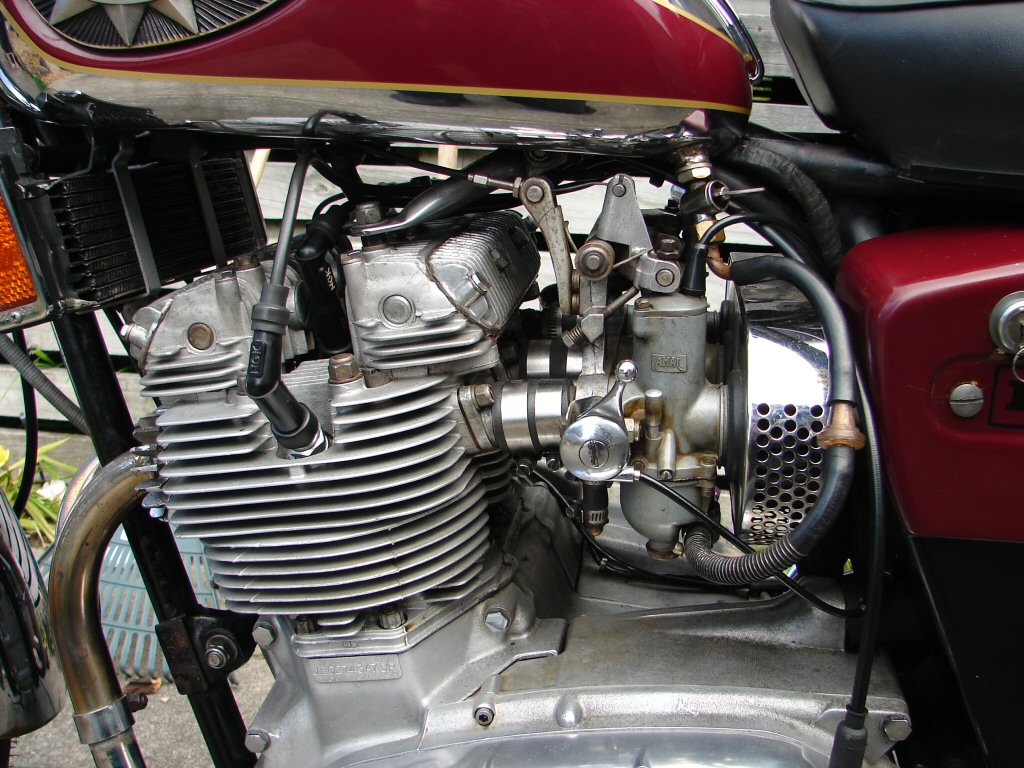

As a consequence of the first test ride I decided to pull the carbs off and check them out. The bike had tended to run rather rich in the past, but I also noticed that it flooded so quickly when using the ticklers that I suspected the floats might be set a bit high.

It was only when I was getting them out that I noticed that a balance system had been added by drilling into the adaptor plate and making pipework to fit. Can't do any harm I guess.

The centre needle had been set a notch higher than the outers, so I rectified that. I am not of the school of thought that the centre cylinder needs any special treatment, and that correct tuning is the best approach. Two of the needle jets had blocked side drillings so I am glad I looked.

The floats were way too high and well proud of the top of the float bowl. I am surprised they had not been in the habit of flooding. I set all 3 to my usual 1-2mm below the top of the float bowl.

Until now, my T160 was the only bike I work on which still has the original nylon float needles, but this still has them too. That would also have a bearing on how quickly it floods.

In my opinion the nylon needles are so light that they give the best fuel flow of any arrangement. Mine have never failed to shut off, and nor does this bike.

The innards were otherwise all rather normal, 3½ slides, T150 needles, 106 needle jets and 150 mains. No surprises there then.

The carbs were in great overall condition and may have been a new set when fitted to this bike. Being 930's they have the idle adjust screw which bears directly on the underside of the slide, so I made sure they were all set well away from making contact. The centre carb has its pilot air screw on the left side, and it is virtually impossible to adjust because of its obscured location, so I took extra care to attempt an accurate static tune on reassembly.

We shall see.

Nothing for it but to see if it is still happy to run.

There is a video of what took place here.

A second test ride was now in order, to make sure everything was working before attempting the compliance test. On the first ride, with a somewhat furry new clutch plate, disengagement was not quite complete during gearchanges, and I was managing to change up and down by 1½ gears at a time, which made things a tad interesting. Having given the linings a bit of a hurry up bedding in by parking the front wheel against my shed and slipping the clutch in second gear, I had improved things a bit, and was now able to make smooth changes, which immediately revealed that we have 5 gears.!

That is something of a bonus.

On my return I removed the airfilter and used my vacuum gauge to balance the carbs more accurately, then a final tweak of the pilot screws before reinstating it all.

There had been another discovery during this ride. The intermittent speedo had stopped before reaching the end of the street, but this time the failure was permanent enough to find the culprit. The drive unit had given up the ghost, so I ordered a new unit immediately.

With the engine still warm I dumped the gearbox oil. I had decided to remove the plunger which bears on the camplate just to ensure there was no undue wear which might have also been influencing the gearchanges, but in fact it came out looking like a fairly new one. All good there then.

I refilled the gearbox with 850ml of my oil of choice, which is a Penrite 75W90 full synthetic, and often affords a slight improvement in gearchanging on these bikes. Now all fluids had been changed and only the arrival of the speedo drive to await to complete the job.

I took the opportunity to take the paperwork to my compliance testing man Tim, to make sure we had everything we would need. He gave it the nod, so I arranged to bring the bike in as soon as it was completed.

Things are moving along.

The speedo drive turned up in two days, so that immediately got fitted.

With the rear wheel restored and the brake and chain adjusted it was time to bite the bullet and attempt a compliance check.

This number plate bears no association with this bike - I just feel naked without one...

While the mechanical inspection of the bike was a roaring success, the paperwork is never straightforward.

Despite the purchase document issued in 1998 by a vehicle dealer clearly stating that the bike was being sold with no registration or wof, it also stated that a number plate had been documented, but had presumably expired.

Of course, that 1998 expired number plate was not in my name, therefore I would be required to produce a statutory declaration to the effect that I had not nicked it.

Surprisingly, my J-P was on holiday in Australia.

My second choice was the local constabulary, but they were closed until 1pm.

I was there when they opened, but they did not like the look of my declaration form, and insisted that I needed to fill out their version instead. It stated that this form was in no way proof of ownership, but merely me saying that I did.

Strangely enough, I had already furnished a receipt signed by the previous owner to exactly that effect. The law is an ass.

I returned with my new piece of paper, and while they completed the paperwork which would allow me to pay yet more fees to actually put a new plate on the bike, the heater hose on my Volvo burst while parked in their parking lot, and poured green antifreeze all over the yard.

With a large bottle of water I scrounged, I limped quietly home, pausing only to drop the Rocket 3 seat off at the place of repair who had told me it would be two weeks before they could do it, two weeks earlier. They promised it would be back 'early next week'.

I made it home, grabbed another car - the trusty Marina - and headed back into the city to buy the number plate. Third time lucky. We had a plate and 12 months rego.

This bike was not going to be sold without a huge fight.!

Allan had never relinquished any of his bikes in the past, and he was not about to start now.

I had a brief conversation with him.. :)

Lo and behold, the seat man phoned the following day to tell me I could pick it up the next morning.

I did so, inbetween Volvo repairs, and was extremely pleased with the finished job, and the less-than-estimated price. A true gentleman indeed.

I raced back home and had the seat refitted before you could say antidisestablishmentarianism...

It is complete.

A lot of time and money went into making it so.

But I was doing it for Allan, and I am as happy with the result as I hope he would have been.

Cheers mate.