July 2022

1974 Triumph T150 Trident 750

My friend Brian asked if I would look at another T150 which had some major oil leaks from the top end. The bike had enjoyed some engine work prior to his buying it, although he observed that they had been "car guys", which I assumed to convey that their expertise with machines that had less wheels might have been less successful.

As he was coming to collect the last repaired bike it seemed logical for him to swap them over, but to my surprise he rode it in. While there was evidence of oil around the head area, I have seen a lot worse considering he had ridden more than 50 miles.

I could see that it had a composite head gasket, but had benefitted from aluminium rocker box base gaskets, so I figured it had probably missed a few necessary head retightens, and that the head gasket would now be in distress. I would need to fit a solid head gasket which would of course mean lifting the head.

So I headed straight there.

As I proceeded to remove the rocker boxes a number of things became obvious.

The first was that someone had fitted lash caps to the valve stems. That was an advanced move of the good type.

The second was that, despite having now extended the length of the valves, they did not reduce the length of the adjusters, which shows a distinct lack of understanding.

This is almost guaranteed to cause contact between the adjusters and the inside of the rocker covers.

Which it had.

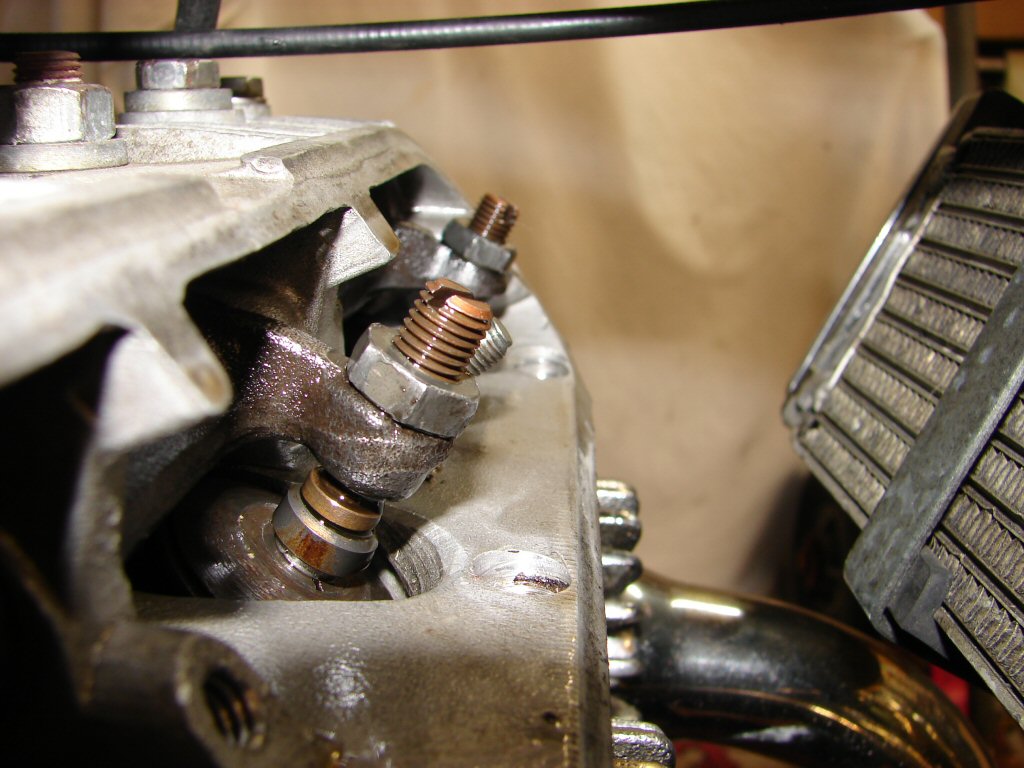

The next thing I found was that the cap screws which anchor the outer edges of the rocker boxes were loose, but they were also a little too short to remain viable without pulling the threads, which some had.

It appeared that these cap screws had been home made - without an adequate plan.

Neither did they feature the alloy washers whose purpose is to prevent oil finding its way down the threads, to drip on the exhaust manifold.

Which it had.

I was beginning to think that this engine had never stood a chance of being oiltight, and I had still not yet gotten to the area from which the major oil leaks would have come.

I figured that the head gasket would have ceased sealing properly due to compression of the composite gasket requiring successive retightenings which had not taken place.

But there were to be more revelations.

Despite the correct pushrod tube seals having been fitted at the bottom, there were only O rings at the top, a la T140, but they would not have worked here.

Unfortunately the aluminium rocker box gaskets wre not well made, and had fouled the head bolts in various places, which would have prevented them from sealing well.

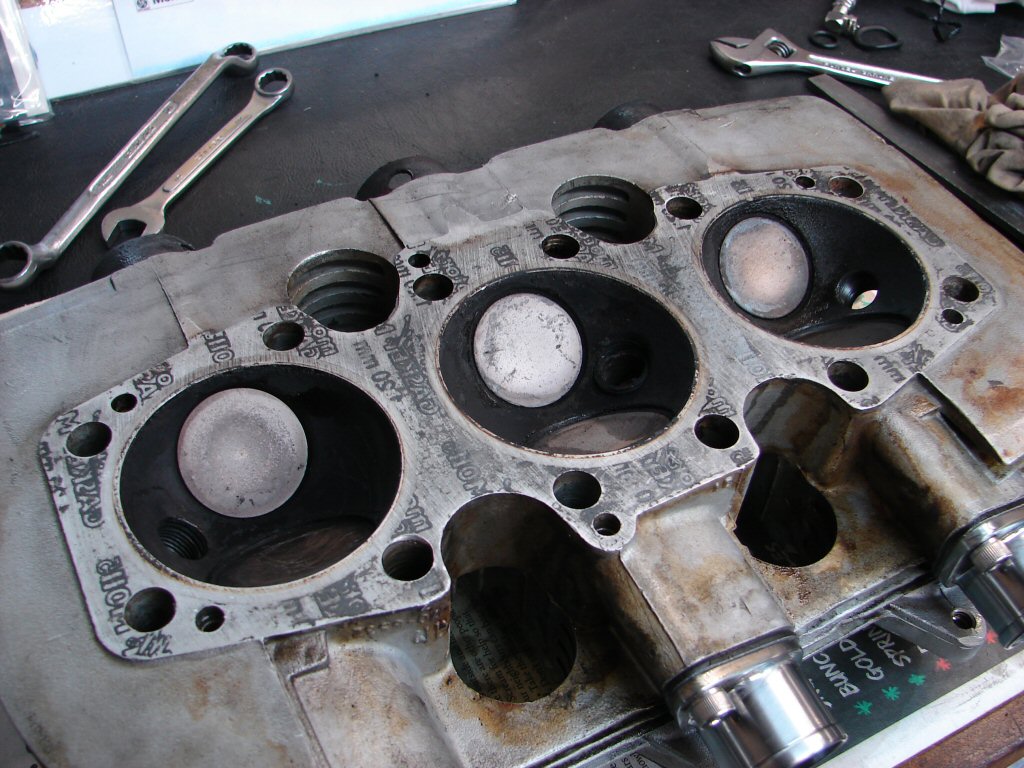

Fortunately the head looked good, and the engine appeared to have been running pretty clean, so I think gaskets only required.

The head gasket was not as bad as I was expecting, but it was destroyed in the process of lifting the head, as it had glued itself to the surface.

But wait - there's more.

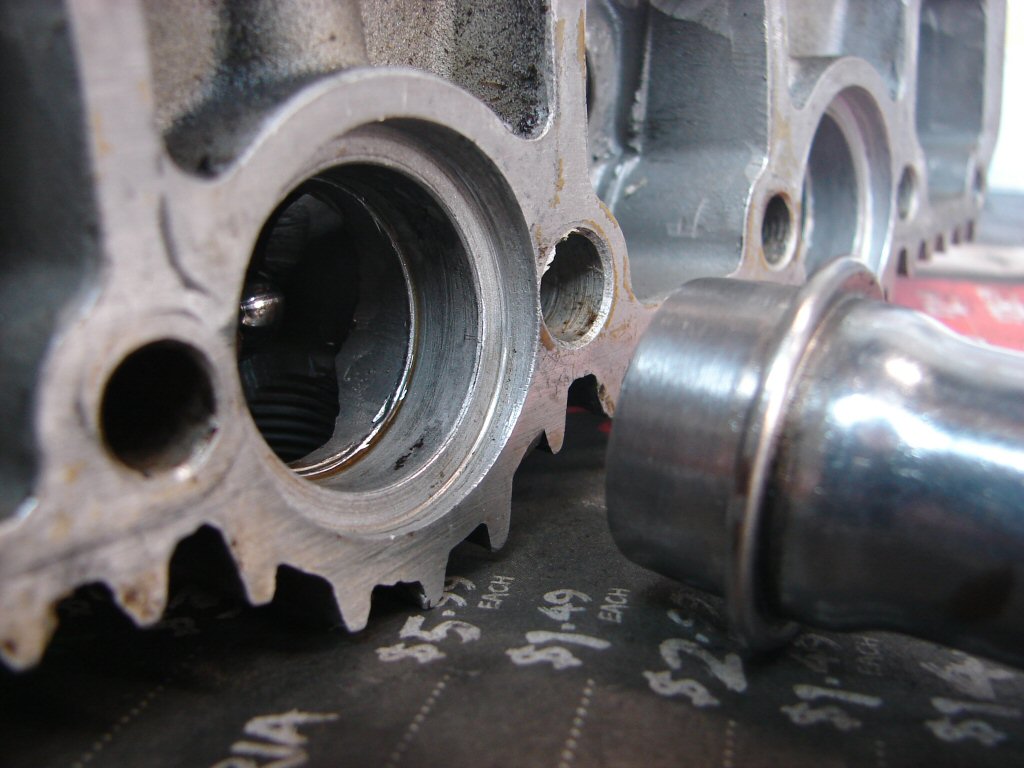

While cleaning the rocker boxes and checking the fit of the pushrod tubes, another problem came to light. And probably another source of oil leaks.

For unknown reasons, the exhaust rocker box had been replaced at some time. Unfortunately, there are two types of rocker boxes, and this was the wrong one. The later engines had pushrod tubes with a longer extension into the rocker boxes, perhaps to discourage oil leaks, but the early ones had a short extension, and they are not interchangeable.

This means that the long pushrod tube will collide with a shoulder inside the rocker box, rather than compress the oil seal.

And so it had.

The easiest solution seemed to be to grind the outside extremities of the two exhaust pushrod tubes until they would fit inside the shoulder.

So I did.

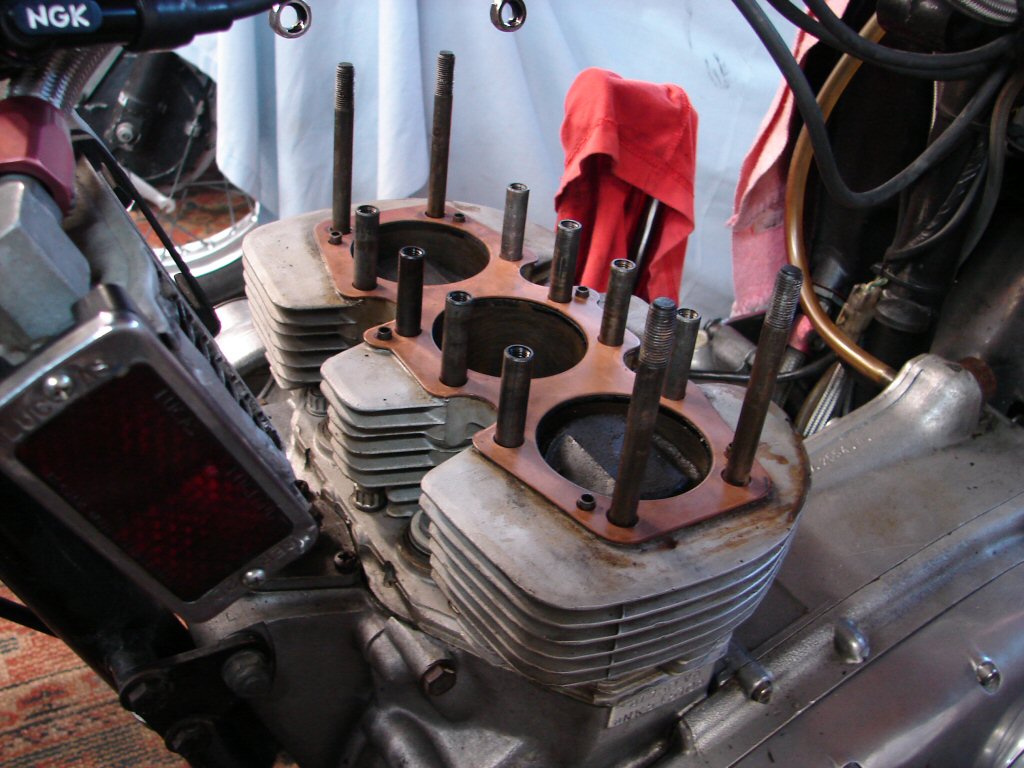

The next thing I discovered was that there were no new copper head gaskets to be had in NZ at this time. Bother. Suppliers have been having trouble sourcing things abroad for reasons of both short supply, and freight holdups. I decided to go with plan 'B'.

I have saved a few old copper gaskets which could be reused at a push, so I annealed one and flattened it as best I could. A good coat of copper spray and it was ready for the acid test.

Prior to this I had checked the clearances beneath the rocker box gaskets to ensure there would be enough crush on the new 'proper' pushrod tube seals, and a new set of short valve adjusters were fitted to the rocker arms, so assembly went full ahead.

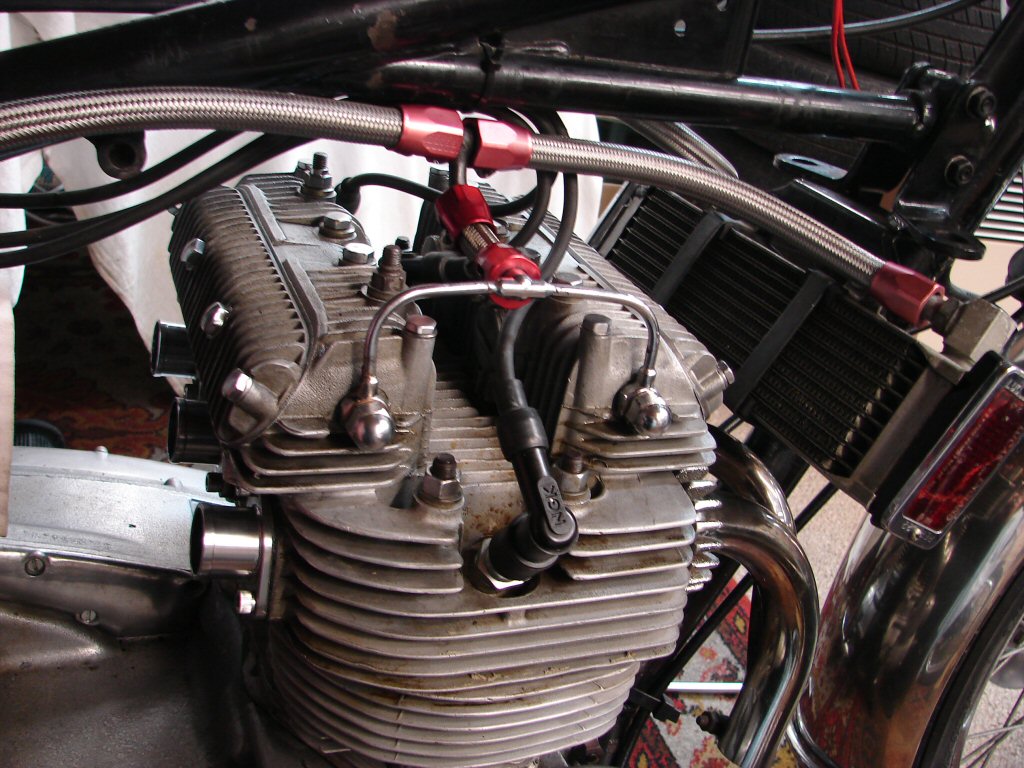

Valve clearances were adjusted and the rocker boxes buttoned up, so now we were here.

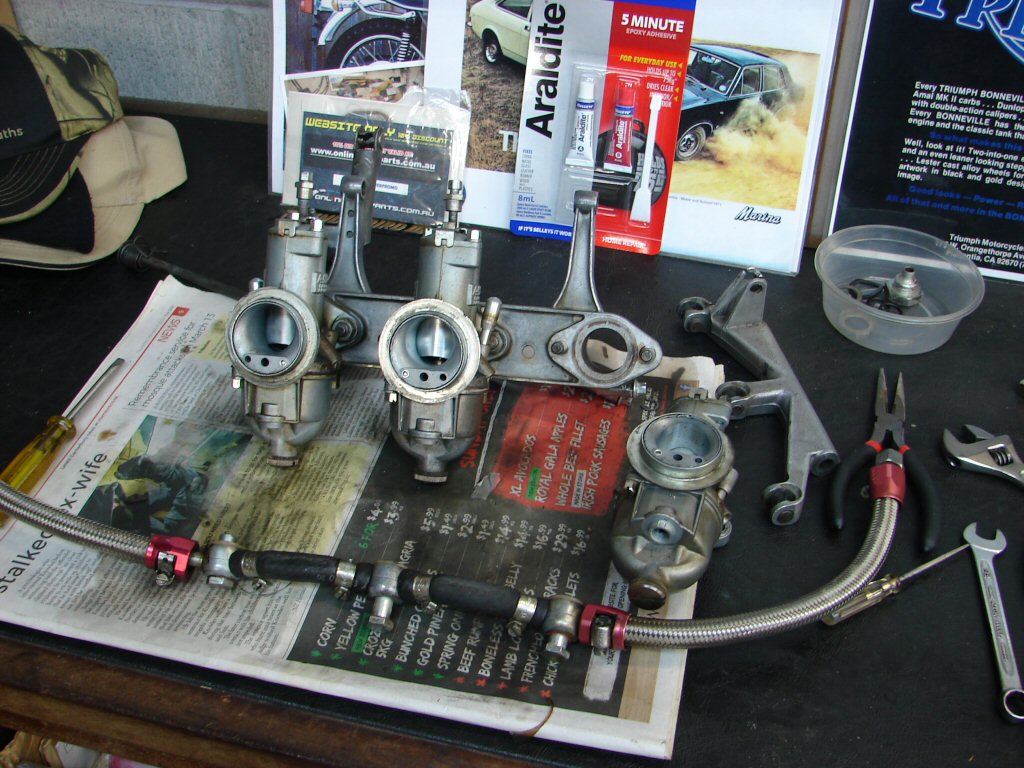

When the carbs are already removed, it is prudent to check their insides, as nothing is certain without looking.

The needle jets were already alloy, which was gratifying, but the floats were too high, so they got adjusted. The operating arm bushes were also slogged out, so a new set were pressed in. A quick synch of the slides using ball bearings and we were good to refit, along with the exhaust.

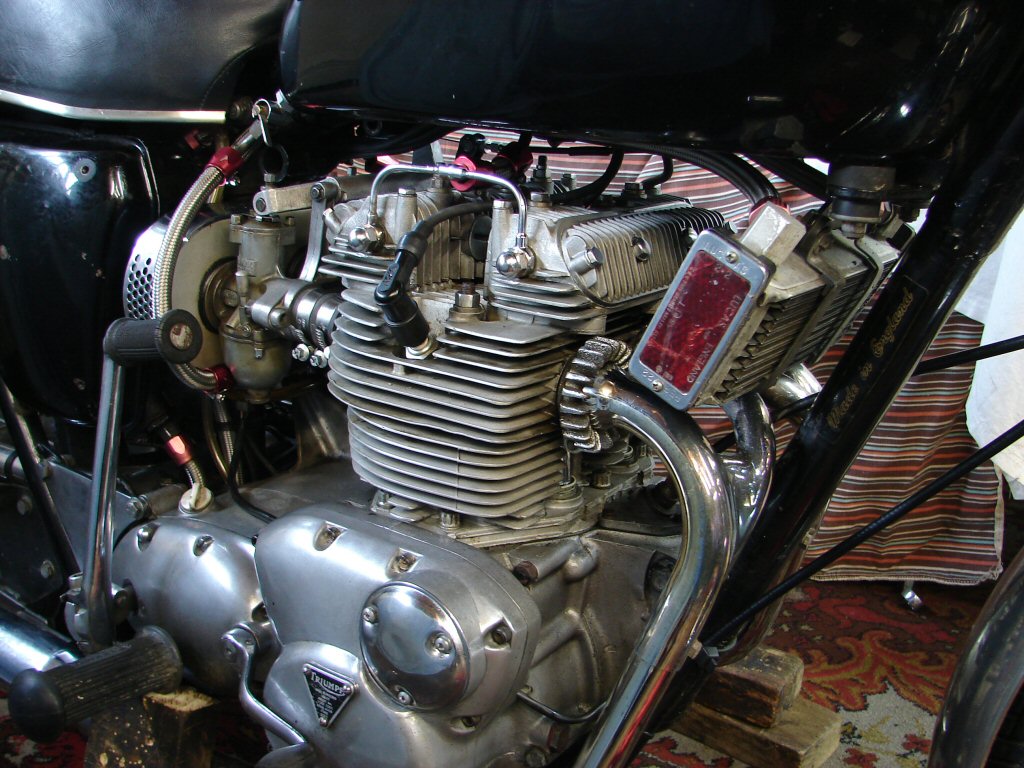

Seat and tank restored and we are looking good for a test run.

The engine started on the third kick and ran happily enough. After a fast idle for a few seconds I gave it a few trial revs, which elicited some escaping combustion gases on the right side. After shutdown an inspection revealed oil leaking from the same area, around the right rear head stud.

After it cooled I ran over the head tension again to see if the gasket might compress down. Second start and sure enough there were no more combustion leaks, but still some oil.

Off came the head again, and the copper gasket got removed. About now I suddenly remembered a special head gasket I had been sent by Triple Tech in Long Beach when I got some pistons from Charlie Barnes. It was a special type of stainless steel layered gasket, with the outer thin layers embossed where all the oil drains and the compustion chambers are, so they would effectively seal under head tension. Not sure if the name "Cometic" was the manufacturer or the type of gasket.

As it met the criteria of being a 'solid' gasket I fitted it and tightened everything back down again.

You can see the short valve adjusters have allowed plenty of clearance in the rocker box.

Third start was a total success, with no leaks of any sort, so we were finally up and running. As the bike came in to cure oil leaks, I did not intend it to have any when it left.

Next thing was to complete a brief test ride, about 3 miles around my usual test roads. The bike performed really well, although I did make some adjustments to the rear brake on my return.

Only other thing was a final tune with the vacuum gauge, and a run around the pilot air screws.

The final move would be to retighten the head and check valve clearances the following day when it was all cool again.

So that happened, and the head did not go down any further, so the valve clearances were just checked. Some extra attention to sealing the rocker box cap screws and it was done.

Outside for a photo then.

All good. I let Brian know it was ready, and he turned up a few days later and rode it home.

He let me know it had arrived home oil tight.

Sweet.!