April 2021

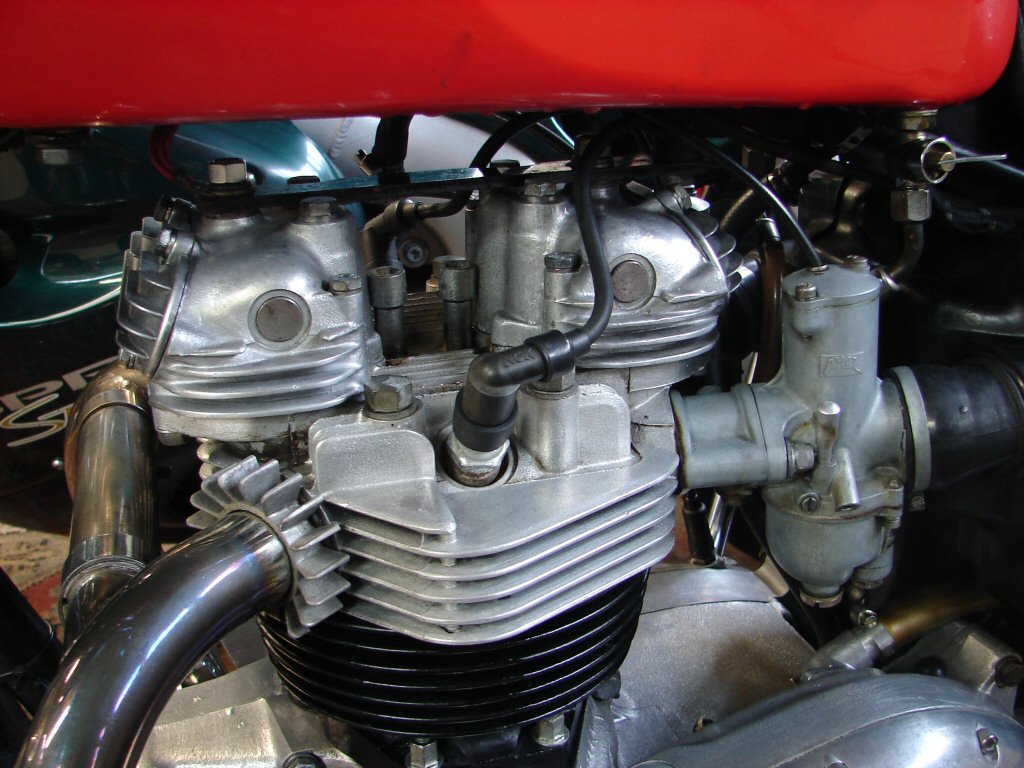

1973 Triumph T140 Bonneville 750

Tommy's Bonnie was still throwing problems despite an intensive engine rebuild in 2012. This time it came in due to persistent oil leaks from around the rockerbox area which had not responded to several head retightening procedures.

Careful inspection revealed that the O ring at the top of the exhaust pushrod tube had split, and oil coming from there was finding its way just about everywhere.

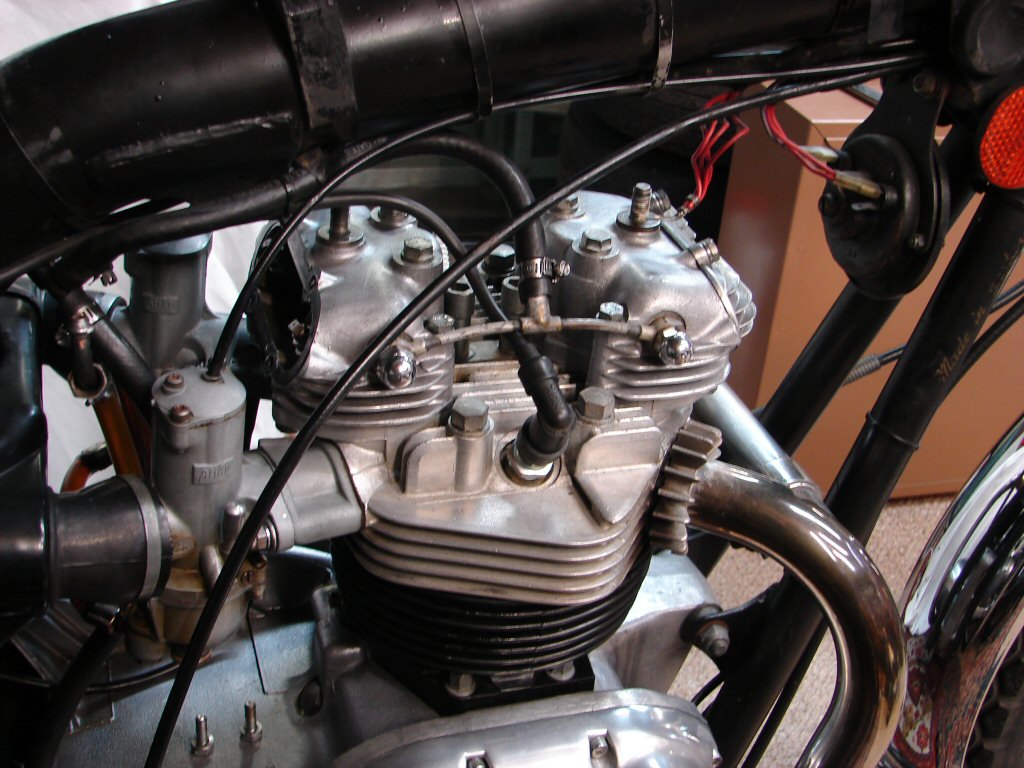

The bitch with the T140 compared to my triples is that the entire cylinder head needs to come off to free the pushrod tubes. So that needed to happen.

Removing the head resulted in the total destruction of the head gasket. The rebuilder had used a composite gasket, which explained why so many retightenings had been required. The resulting compression probably caused the failure of the O ring as it reached its own compression limit.

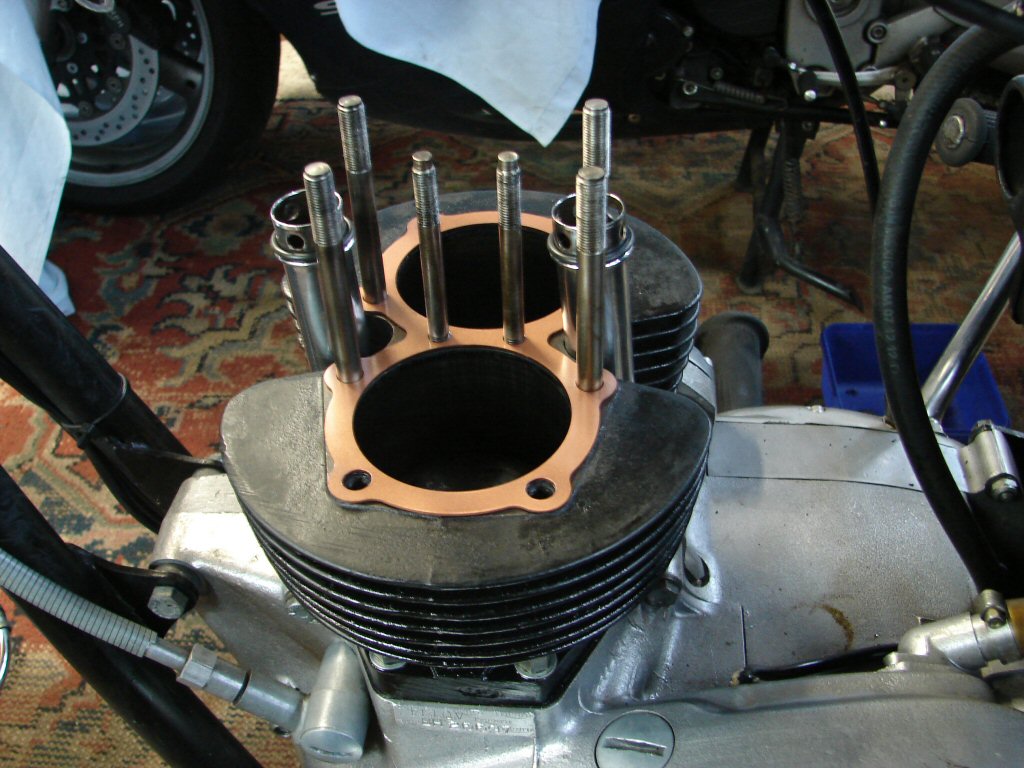

Cleaning the head and barrel surfaces up was a laborious task, as the gasket had firmly bonded itself to both, thus it disintegrated rather than pulling away. I chose to replace it with a copper gasket, which would give a more stable joint in future.

Before dropping the head back on, a coating of copper gasket spray was applied, as this would help seal any small irregularities in the surfaces should there be any.

During the reassembly a stripped stud on the rockerbox came to light. I doubt that this occurred during the rebuild, simply because it looked like a fairly old event - likely over several previous interventions.

The old stud put up one hell of a fight, which made me think others may have given up on it in the past. I gave it to my engine machinist and he got very serious with it. These things are the achilles heel of any reassembly, so they simply have to be addressed.

After that it all went back together happily, and started and ran without any trouble. It continues to do so.

One unexpected bonus is that the thicker copper gasket has reduced the compression very slightly, making kickstarting a less arduous procedure.

So thats nice...