January 2020

1975 Triumph T160 Trident 750

This bike had been behaving very well since its previous work except for a fairly copious oil leak which was emanating from beneath the clutch cavity. It was engine oil so it seemed logical that one of the oil seals from the primary outer chaincase was not doing its job. This would either be the clutch pullrod seal or the clutch drive seal, and as that was far the larger of the two my money was on it as the culprit.

Otherwise the bike did everything rather well, although the spark plugs were still a bit sooty and it was hard to tell if it might be fuel or oil related. Or both. Looks nice though.

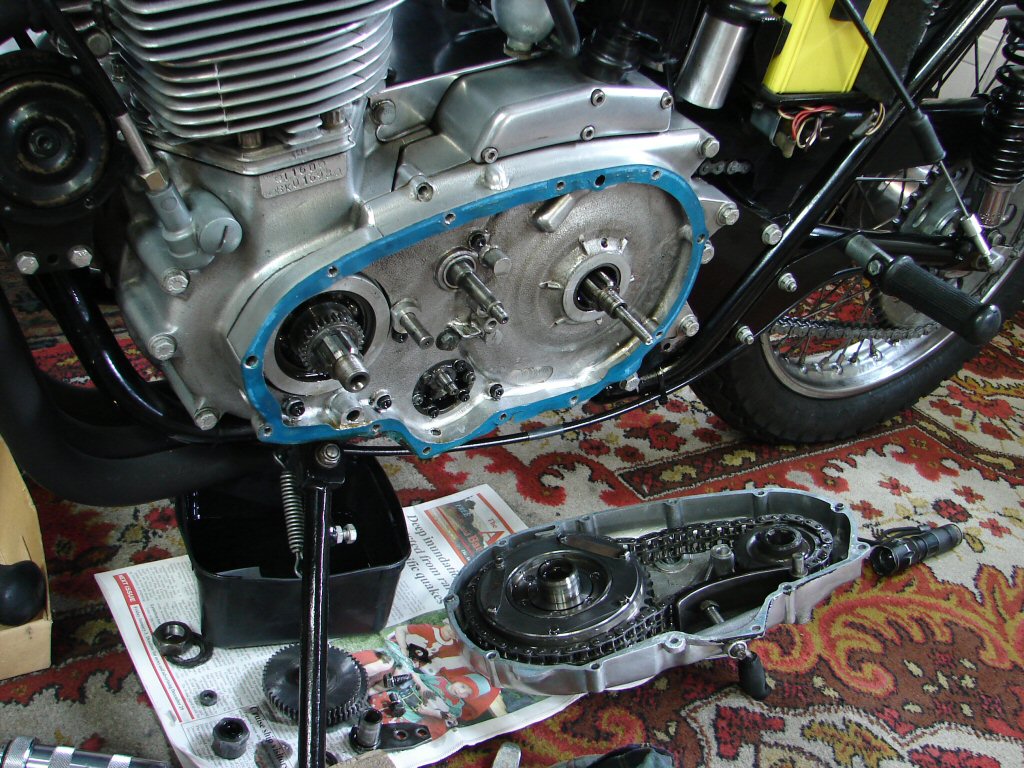

Primary oil drained. Footpeg removed. Clutch cover removed and cable and pullrod released, then outer cover off. Everything looked to be clean and in good shape. Primary sprocket and cush drive nuts were very tight, as you would want, but they came off ok and everything came apart in a most agreeable way. I'm liking it so far.

Inner cover now removed with no drama, and the clutch came out with a lot of oil apparent on the outside of the cover plate, so the oil was indeed coming in via the drive seal. On close inspection, the seal had moved out of its housing slightly, but was also a rather loose fit on the cush drive extension.

I spent a lot of time cleaning all the cases up and removing old gaskets, then after completely removing the seal I mounted the cush drive sprocket inside the two cases so that I could ascertain the condition of the two needle roller bearings that it spins between. They seemed ok and still fit for service. I just wanted to be sure that the seal had not been unable to cope with too much side play if the bearings were worn out.

Decision was made to replace both of the suspect oil seals anyway, along with the now disturbed gaskets, an oil pump o ring and a missing tab washer. The clutch hub would get a smear of grease as it was obviously dry and slightly rusty. I refitted the oil pump drive gear and whizzed it around to drain the sump, as oil was leaking out through one of the threaded holes in the crankcase. Did not take very long, and I was able to see that the oil light would go out in only one complete revolution of the pump. Nice.

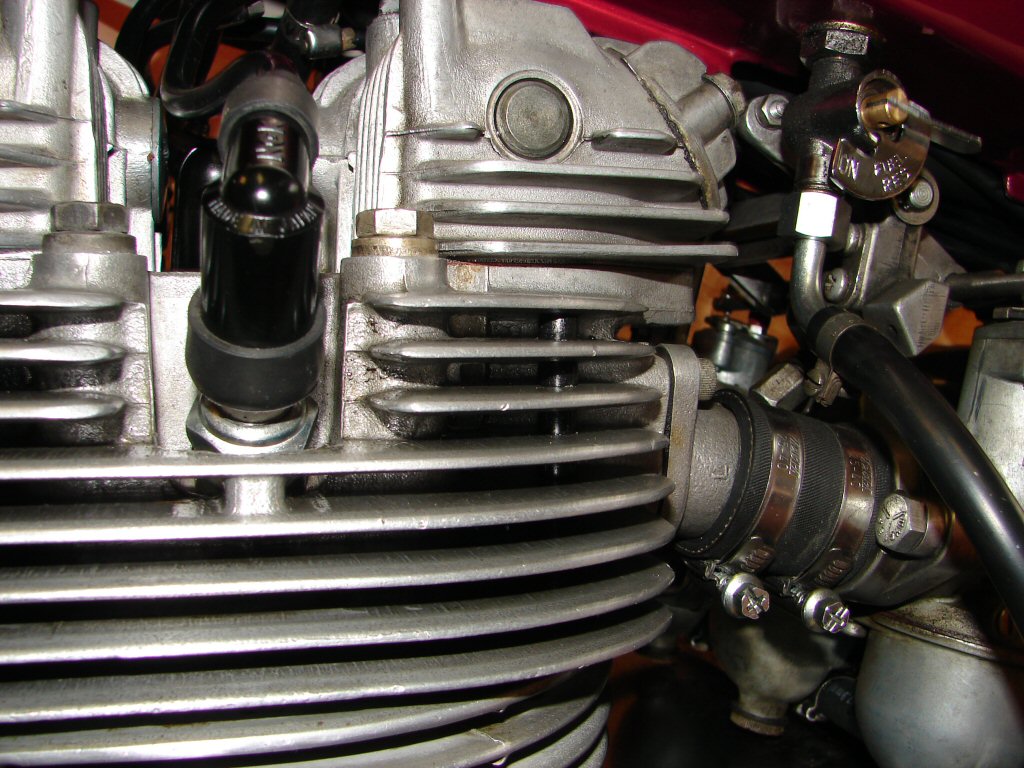

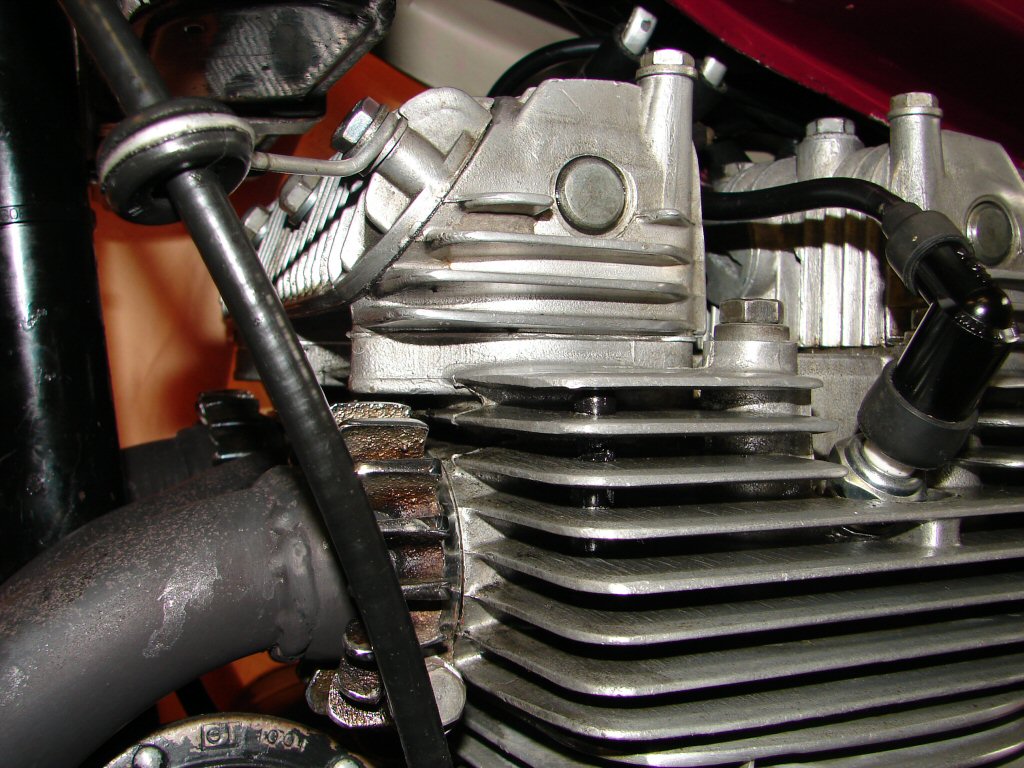

The primary drive reassembled in excellent fashion, and light use of sealants would ensure that oil did not travel along splines and nuts would not fall off. I refilled its oil and buttoned it all up. The next problem was some oil seepage from around the exhaust rocker box base gasket. This had appeared when the engine was first put together, and it transpired that the allen screws along the front inner edge were not completely tight, but attending to that had made no appreciable difference. When I opened it up this time the allen screws were loose again, so I removed them and inspected things. The threads were in good shape both on the screws and more importantly, in the head, and new alloy washers had been fitted, along with sealant down the threads as it went together. Hard to fault it but still there was a problem. I tried tightening it all down again firmly, but still the problem persisted, so it was decided to replace the thin copper gasket with a thicker alloy one. I prefer the alloy gaskets but they had been unavailable at the time we assembled this engine so the copper ones were used.

Although the inlet rocker box gasket seems to be doing its job, it can be seen that the copper gasket is very thin. Initially they were fitted with a coating of copper spray, but when the exhaust one was refitted the gasket was smeared with silicone sealant, but that did not provide a cure either. When the copper gasket was removed completely the reason was discovered. The holes in the gasket were far from accurately matching the positions of the holes in the rocker box, so the various studs and allen screws had been catching the edge of the holes in the copper and distorting them, picking up burrs which then prevented the box from pulling down flat on the head. What a nuisance.

Because the alloy gasket is at least twice the thickness, some of the compression of the pushrod tube seals is lost, so an extra fibre washer had to be added beneath the lower seal cups, and this supplied the correct 'squeeze' once again. The holes in the alloy gasket were perfectly matched to those in the rocker box, so on it went with a light smear of silicone. Everything went together sweetly and the studs and screws felt much freer in their threads. Easy to notice such things after the puzzle has been solved.!

A trial run proved that we were now indeed oiltight, so great relief. Probably should have replaced the inlet gasket as well, but time will tell if it had suffered the same fate.

Next job was to fit a relay in order to improve the electric starting. The Boyer electronic ignition has an achilles heel in the form of its sensitivity to voltage. Anything below 9 volts pretty well dooms it to damp squib status. While most batteries and wiring looms can provide more than enough to please it, the effect of cranking a hungry starter motor can change all that. For interest sake I attached a voltmeter to the Boyer connections and cranked the starter, and there we had a magnificent 8.75 volts doing its thing. Or not. I fitted a relay where the condensers used to reside behind the side panel, extended a few wires and tidied some of the existing wiring. A second attempt now elicited an improved 11.5 volts, and with a brief flooding of the carbs we had life. I tried several times and the starting was totally effective and seemingly reliable. Some restraint about riding with a high wattage headlight may be wise however. I do find the reassuring 'click' of the relay when the ignition switch is operated to be an easy faultfinding tool, so am much in favour of this mod. So is one's right leg...

Final move was to reroute the speedo cable where it had been run outside the swingarm mount, and while the cable was undone a new grommet was fitted beneath the speedo. Same was done for the tacho, as neither had been in place and they do prevent weather entering the inside of the gauges.

The bike was delivered back to its happy owner on 20 January 2020 and hopefully a few rides will take place over the next week so the head tension can be checked before we head for the Bert Munro in a few weeks.

So the head got checked again, but the tension did not alter - a benefit of using solid rocker box base gaskets. On the morning of our departure for the Burt Munro the bike arrived with a misfire which got worse over the first few miles to our first rendezvous point. One of the plugs looked a bit suss, and the owner had a spare set, so they were fitted and the bike was happy again.

The T160 was the only 70's bike in the group, but performed flawlessly through the pouring rain on our first day, and all the extra miles we did looking for a way past the flooded roads south. The rocker boxes remained oiltight and we began to relax in the reliability of this now slightly proven machine. The lineup in Riverton.

A thousand miles later, as we arrived in Hokitika, a rider commented that the T160 was smoking slightly, and we immediately discovered that the rear of the bike was covered in oil. I had seen this exact same thing before when the oil filter cap on a T160 popped a thread. Sure enough this had happened, simply a legacy of the very poor threads which were cast into the alloy cap.

We were able to refit it with some plumbing thread tape, and replace about 2 litres of oil that had gone missing. Could have been fatal if we had not stopped.

The bike got thoroughly cleaned and was serviceable for the final leg back to Christchurch next morning. We took a shortcut in the form of the old christchurch road just north of Hokitika, which turns to gravel a few miles before rejoining the main highway east of Kumara. As we stopped at the junction I noticed spots of oil in the dust beneath the bike, so we had another go at plugging the leak with even more thread tape.

From there we could not be sure if it would stay in place or not, so it seemed prudent to keep the revs down as that would reduce the amount of oil pressure behind the cap.

It worked ok, and the bike made it home without further mishap. Currently receiving a replacement cap.

A couple of lucky escapes there, as it is doubtful the rider would see the oil light come on in time to prevent damage if the cap popped right out.

Seems this bike has a charmed life.