February 2018

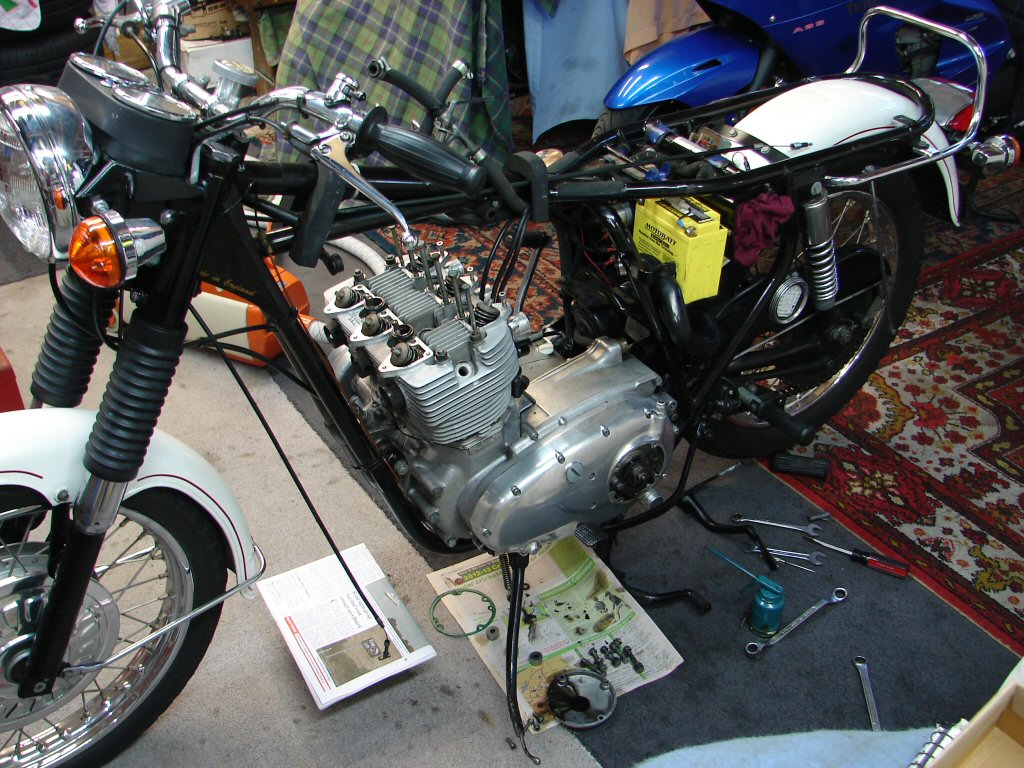

1969 BSA Rocket 3 750

Allan's hallmark white Rocket 3 came my way after the recent BSA rally. The front forks needed attention, as the gaiters were breaking up, and the seals were leaking. Also some small but annoying leaks from the rocker boxes were announcing that their gaskets were breaking up too.

I was not to know that it would be several years before the bike left.

Not that it is an unpleasant bike to have around, and I had storage for it at the time, but things go wrong with bikes even when they are doing nothing.

For now though, there was work to be done. The forks came apart as the first move, and everything got stripped and cleaned before the rebuild began.

All the parts were in great condition, and they went back together happily with new seals, gaiters and heavier oil, along with a pair of 'sidecar' springs, which are a bit beefier than standard. This was hoped to both firm things up, and to lift the front end a little which would in turn improve cornering clearance.

It certainly gained a little height.

The bike rode better than hoped, as all the changes worked well together. Work otherwise stopped there, and Allan rode it on the occasions when he was visiting.

It was in fact February 2019 before the leaks became too enthusiastic to ignore any further, so the rocker boxes came off to reveal exactly what I thought we would find.

Unfortunately it revealed a few other things as well, but I felt extremely pleased we had discovered them, as worse would have followed otherwise.

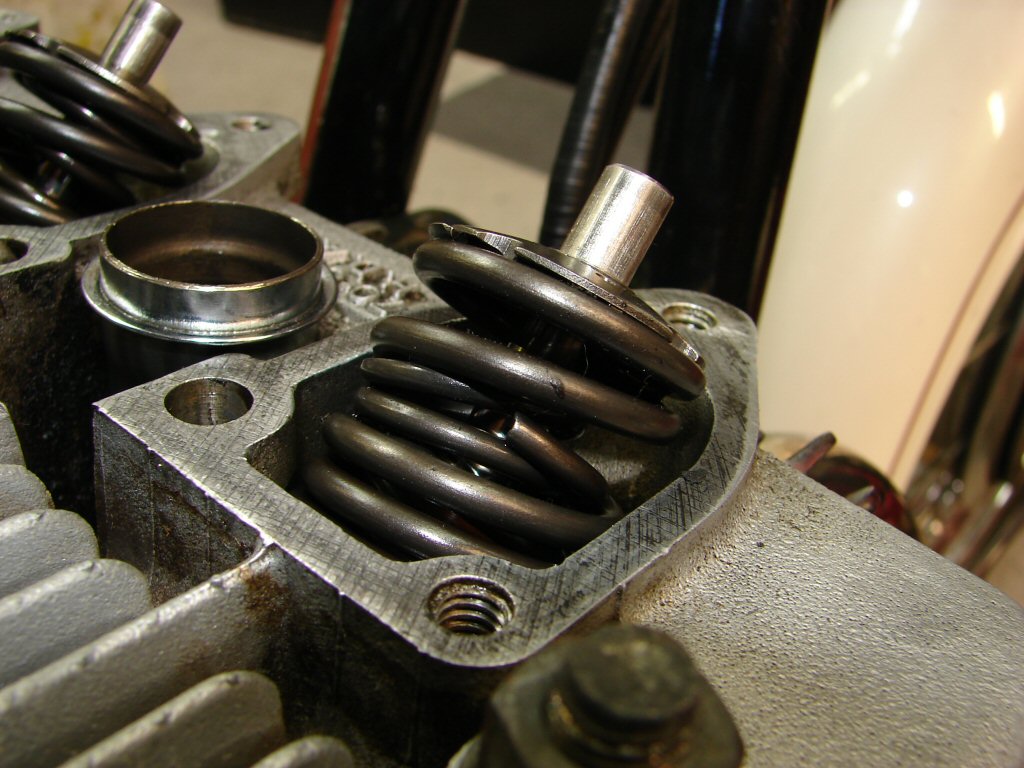

Along with some serious gasflowing of both head and ports, the inlet stubs and carbs had also been smoothed and opened out some. The problem though, was some lightweight valve spring retainers, which had broken at the bottom, allowing the inner and outer springs to get together, which they had not enjoyed.

Consequently the exhaust system and the head came off, and a new set of standard valve spring retainers were fitted, along with new springs.

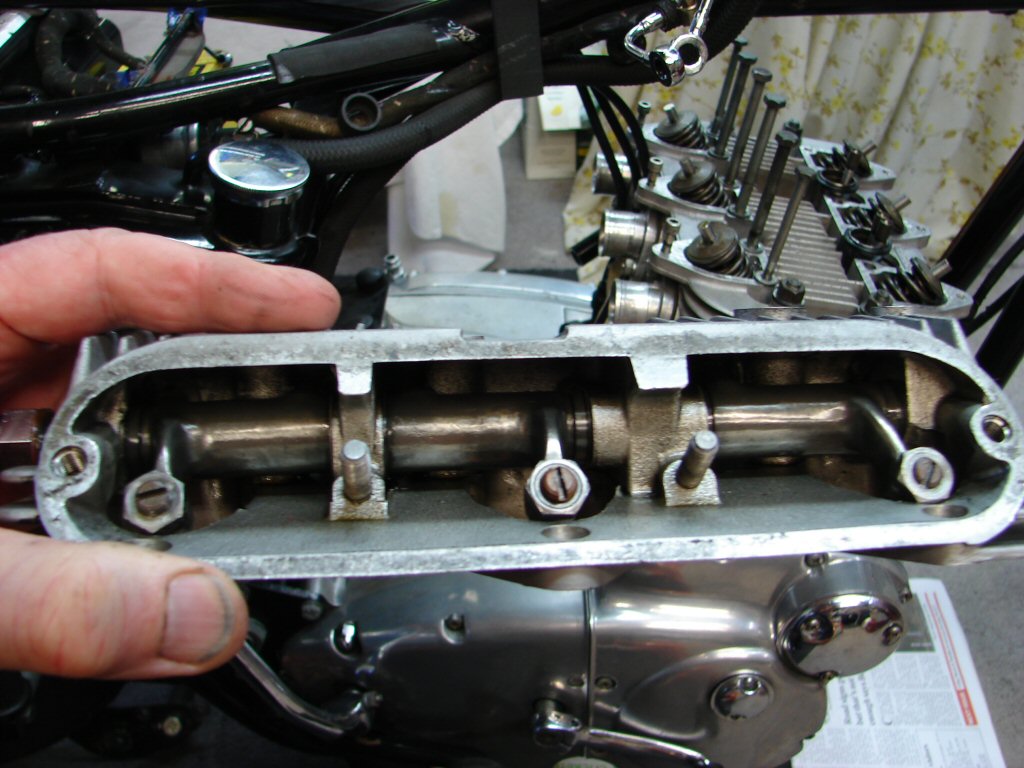

Stripping the head showed just how thorough the porting work had been, and to a very good standard.

While the pistons got decarbed and the rest of the bits got cleaned up, the head went off to the engine reconditioner to have valves and seats refaced and a light surface grind to ensure everything was going to come together nicely. I was tossing up between the original type pushrod tube seals and the later x-ring type. It turned out that there was not a lot of compression available for the seals so I opted for the x-rings as they seal with a bit less pressure.

At the same time some work was undertaken in the clutch adjustment area. The cable boot was well past its best-by date, plus the poorly fitting adjuster had allowed yet another oil leak to develop, this one dumping a fair amount of oil down the chaincase and over the footpeg and engine mounting plate - the latter which needed to be removed to get enough clearance to remove the clutch adjuster cover. What a bitch the engine plate is to deal with. Makes the T160 seem very simplistic in the same area.

Preparing the exhaust rocker box exposed some more trickery - smoothed rocker arms with spacers in place of the usual spring washers. This explained why they dropped under their own weight, but this did present a few new annoyances during assembly.

The rocker boxes then got exactly the same gasket treatment as the head gasket, with an even spray coating on annealed copper, and they were all immediately bolted down to settle in overnight.

Head steadies and oil cooler adornments would remain off until the first ride and head retension were complete.

Carbs and airfilter were refitted, then the fuel tank dropped on prior to first startup. Clutch ops were also completed and clutch statically adjusted to come free at roughly half lever travel.

Exhausts and mufflers were being cleaned and polished thoroughly before refitting began. Everything goes back on cleaner than it comes off..

With exhausts on the engine was coaxed into life. It took quite a few kicks, possibly due to old fuel, but once running seemed happy to idle and revved freely. For the first time I could remember in the knowing of this bike it sounded as though it had hot cams fitted, which would not be at all unusual considering the obvious performance work done.

First ride of about 5 miles was completed with no drama and no oil leaks anywhere. Engine felt to have more instant response than previously, and it is likely it now has more compression than before. After cooling the cylinder head tension and valve clearances were adjusted. Virtually no movement anywhere which is another bonus of using solid gaskets above and below the head.

The bike stayed on a bit longer, and on the last occasion that Allan came to ride it, he only made it to the nearest gas station whereupon it sprang the most hideous leak from the top end. Play was immediatelty cancelled and we limped home.

The previous owner who did all the tricky work had included the T160 style dual oil feeds to the rocker boxes. He had also gone to the bother of having them chromed. Whether that had anything to do with it, the banjo for the inlet feed had developed a tiny crack, but even with cold oil, the amount that escaped was astounding.

A new pair were obtained from the UK, so it was late September before they were reinstated.

From memory the bike stayed locally until the next BSA rally in February 2021, but it enjoyed a momentous lineup when I emptied my shed in late September 2020.

I love triples.!