May 2017

1972 Triumph T150 Trident 750

A new acquaintance via an old one got in touch. He had purchased a T150 and had some problems that he would like me to check out. I suggested he could bring it over on the weekend. He said "how about tonight..?" I concurred but knew that at this time of year I would hardly be able to see it let alone diagnose it.

Around the appointed time I heard a triple nearby and went out to signal that he was at the right address. It had a nasty rattle as it approached and was running on less than 3 cylinders. I told him that he obviously had some serious problems with his valve gear and should not ride it any further than he had to. Although I was reaching a critical point in another rebuild I offered to accept it over the coming weekend.

It was duly delivered and while the owner was present I removed the fuel tank and the exhaust rocker box cover. It was quickly evident that the valve adjusters which were of the ball-in-socket type had begun to disintegrate, and in some instances had succeeded. There was 1/4" clearance on one adjuster. The valve stems were badly pitted and the exhaust valves at least would likely need replacing.

The head had been fitted last with copious quantities of red silicone sealant, and had some apparently replacement exhaust pushrods, so it would seem that there had been issues in here before.

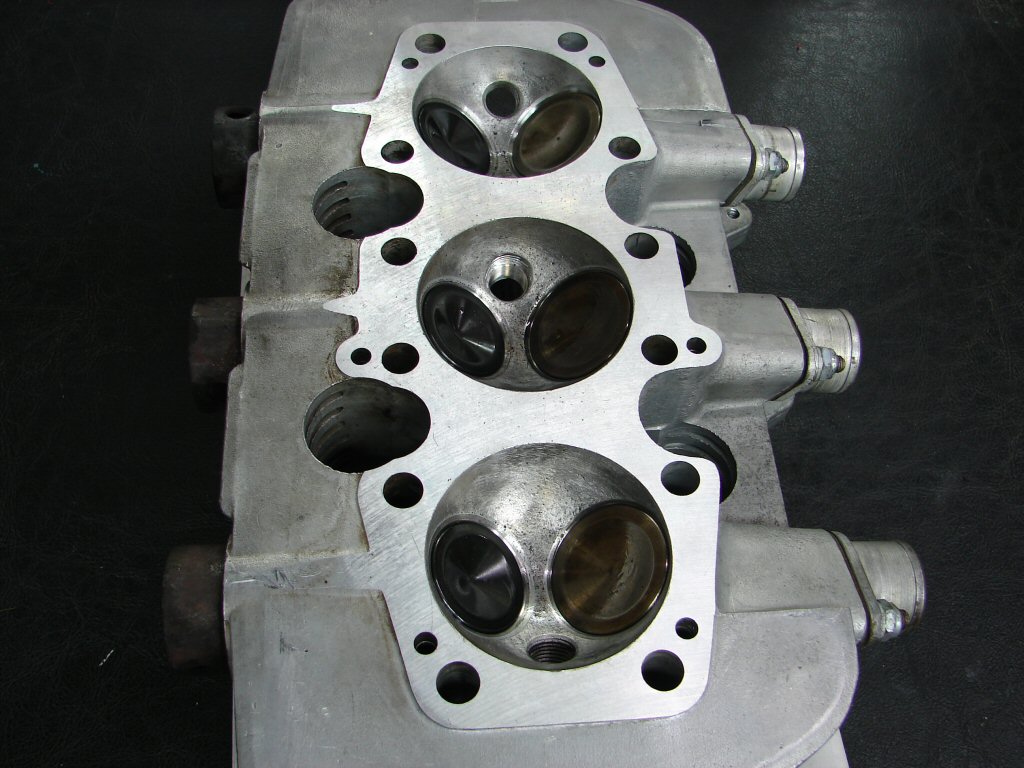

The head came off without drama and the bores seemed ok and the pistons a good fit. It looked that it would clean up rather well. The head had received some porting work at some stage, which was a bonus. The engine number was a later model than the frame, and it had a 5 speed gearbox, so perhaps the valve adjusters had been original fitments in this engine.

The head went off to receive new exhaust valves and guides, the inlets would do another tour although the valve stems would need to be ground. Meanwhile I cleaned everything up and satisfied myself that the head gasket would be fine to reuse with an anneal.

While waiting for the head work to be completed I decided to pull the sump plate off to see what condition the bottom end might be in. I began to find lockwire in various strategic places. The bike had obviously been raced. Looking inside the crankcase revealed that there had been a recent bottom end as there were new locking nuts on the big end bolts, and as racers would not risk bottom end failures I figured that this bike might prove to have been a very good find.

The head came back with new exhaust valves and guides as anticipated, and the inlets deemed fit for further service. The inlets were rather low in their seats which appeared to be a legacy of previous head jobs, but with the stems having been ground to address the damage caused by the failed adjusters we should be back in a good geometric match between valves and rockers. The head had also received a mild surface grind to get it entirely flat again.

The head went back on with its annealed copper gasket coated with copper spray to aid sealing. New valve adjusters were fitted prior to also adding the rocker boxes using aluminium gaskets with similar copper spray.

I had discovered that the exhaust manifold was actually one from a BSA Rocket 3, and as such it had the wrong angle to the downpipes, but the previous builders had simply pushed the headers into the manifold then bent them back to fit. As I currently had a very high quality low mileage manifold on hand it was decided to fit that instead. It improved both fit and looks tremendously. Enthused by that I also added a new set of finned clamps.

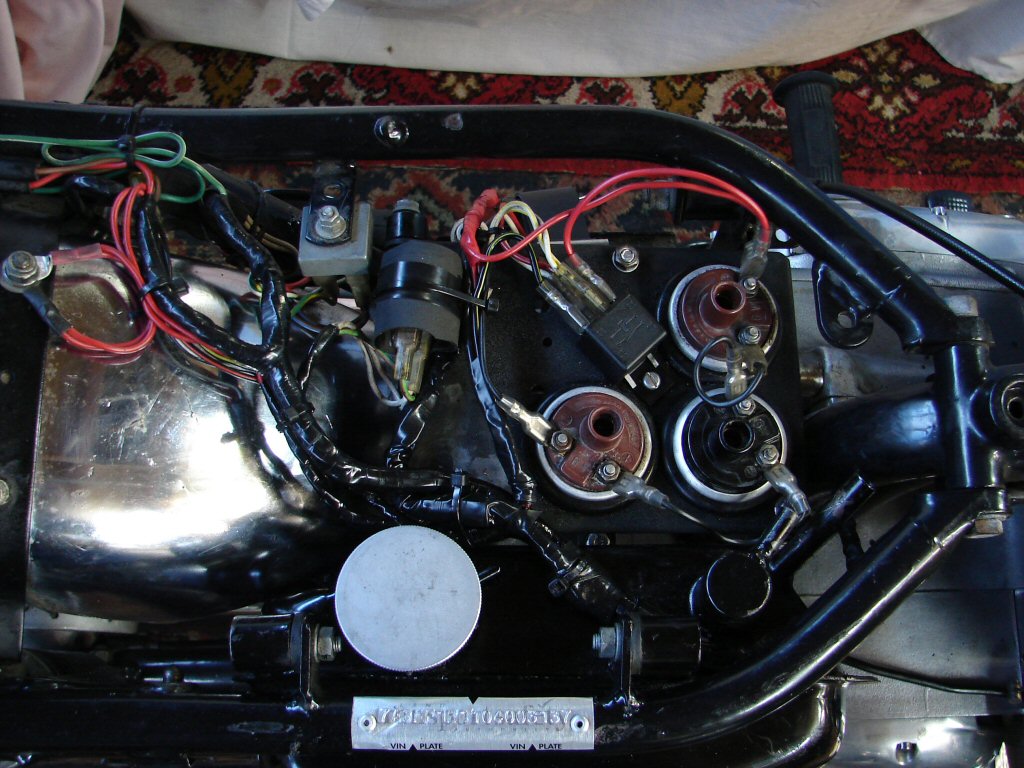

There had been some reported electrical issues as well, so I checked the current status and found a fair bit of voltage going missing in the wiring loom. As the bike had a Boyer electronic ignition which does not enjoy voltage drop I fitted a relay near the black box to make sure the Boyer got all that was available.

The carbs were tuned and received a few new jets and needles, then synchronised as well as possible before the first run. I then found that both fuel and oil lines were in a sorry state, so all were replaced rather than risk any untoward events in future.

First start was a trouble-free event, and all errant noises were gone and the bike idled happily on 3 cylinders. I fitted an oil pressure gauge and found we had over 100psi on cold start, and later 40psi on hot idle, so the bottom end was indeed very healthy.

Riding the bike was impressive. In a rare discovery, the conical front brake proved to be a good stopper, even more so after I adjusted it a little. The engine felt to have lots of power and was eager to rev, which was a good sign. After about 50 miles I torqued the head down and checked the valve clearances before handing it back to a happy owner.

What appeared to have been a bad buy turned out to be a very good find here. The bike was purchased with obvious problems so was cheap, but even including the money spent on bringing it up to scratch, it now seemed to be excellent value for money in light of its obvious performance and overall condition.

Not many times has this turned out to be the case. Most pleasing.