May 2015

1975 Triumph T160 Trident 750

A friend in Blenheim had a rather nice T160 and I had looked at it a few times in the past. On one occasion we had discovered that it had a leaking head gasket, so I replaced it during a weekend visit, but it was in trouble again not long after, and as it had a few stripped head studs it was decided to bring it down to me for a more comprehensive approach.

I began stripping it pretty soon after it arrived.

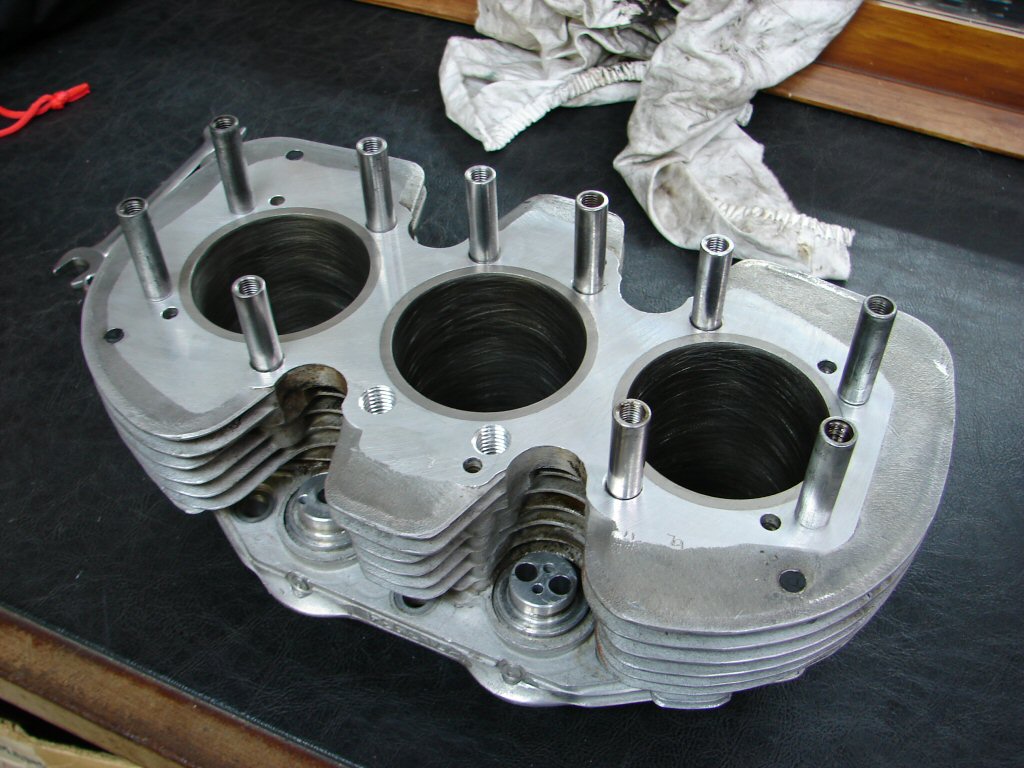

As is often the way, the real reasons are revealed once you begin pulling things apart. Not only were there a whole lot of stripped threads in the barrels, but the reason for that was self-evident. All the cylinder liners had dropped in the alloy barrel, so there was nothing for the head gasket to seal against closest to the cylinders. This would have caused a lot of head gasket problems, and that usually results in operators overtightening the cylinder head bolts to try and cure the problem. Of course without addressing the real cause things are bound to get worse.

My course of action would be to machine the top of the barrels completely flat, including the cylinder liners, then to fit 8 oversize pillar studs so that all the stripped threads would not only be dealt with, but would be stronger than ever before.

The head was in good shape so it ended up just getting a good cleanup and a modest valve/seat reface. Surface was checked and found to be only needing a clean. The obvious signs of combustion leakage were due to the cylinder problems and there was no need for a surface grind. I am never in a hurry to remove metal unless necessary.

Fitting the barrels over the piston rings is always the most interesting part of the reassembly. I use the word "interesting" because it is a job that requires a lot of concentration and usually more hands than are available, so you need to set aside some time that will not be disturbed before you start. This one went well.

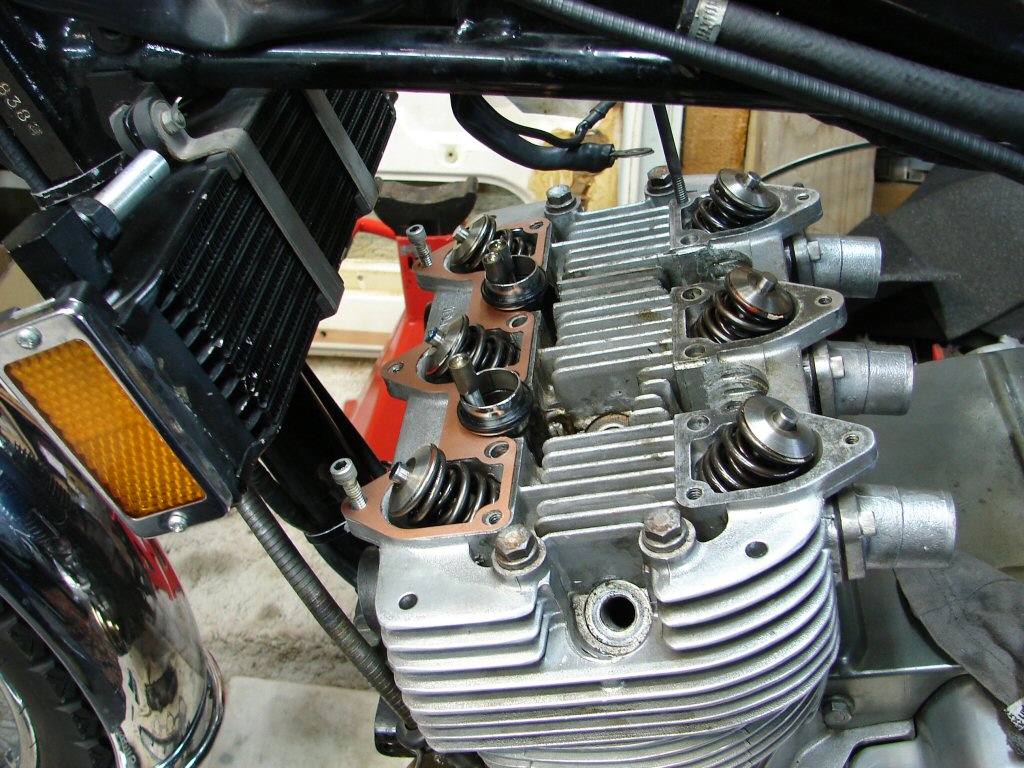

In accordance with current practice I anneal the copper head gasket, then coat both sides with a copper gasket spray. This seems to result in the most effective seal and yet it comes apart again ok when necessary, so I guess it is the best of both worlds.

Head goes on then the rocker box gaskets get the same approach. These are actually aluminium gaskets but once again with a copper coating. I believe this treatment also allows the best heat transfer between all the joined surfaces.

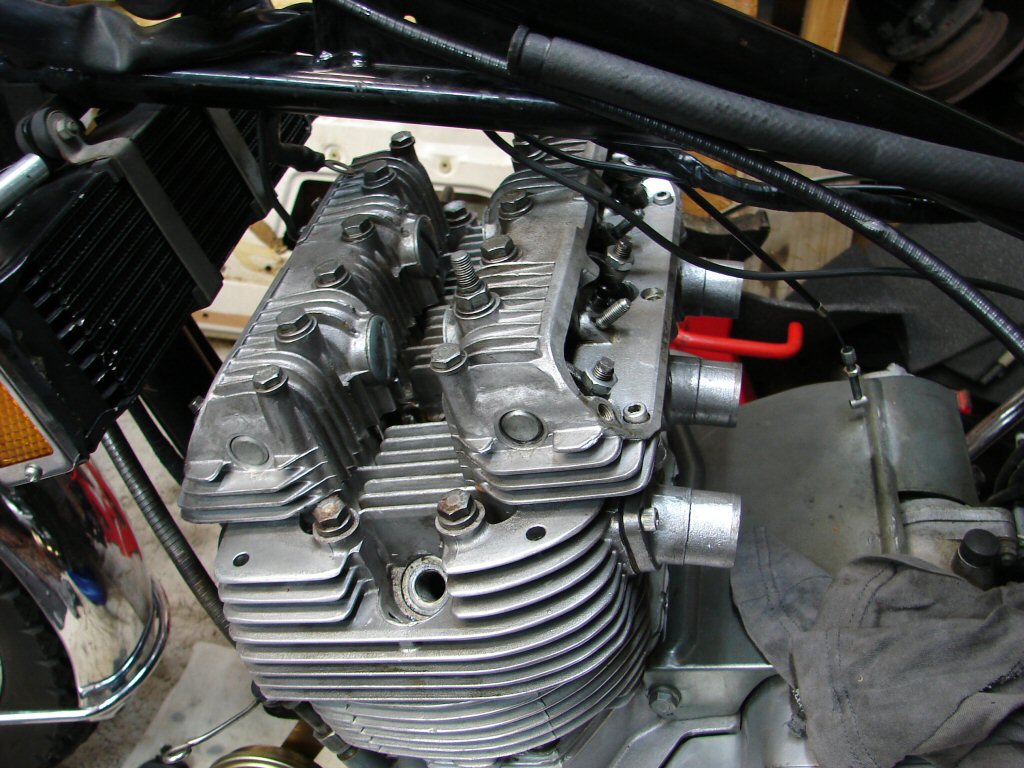

Before final fitting of the rocker boxes the amount of pushrod seal compression is checked by putting it together without the pushrods in place. If inadequate, more gaskets are added beneath the lower seal cups. After that the whole thing gets bolted together and torqued down.

First time I have ever been able to torque all these head studs down.!

Another required manoeuvre was to replace the rear tyre. In the process of doing so I found that when I tightened the rear axle nut, the wheel partially seized up. It took a while to find the culprit, but the nuts on the rear sprocket were fouling on the speedo drive, and appeared to have been doing so for some time. As there was also a slight gap between the wheel and its components and the inside of the swingarm it seemed that a spacer might be undersize.

As I needed the speedo drive to move slightly away from the wheel I removed the spacer underneath that. It appeared to be of the correct dimension, but I chose to fit a slim circlip over the inner end so that it was held between the spacer and the wheel bearing. This had the desired effect of both allowing clearance for the speedo drive, but also caused the wheel assembly to now become a neat fit inside the swingarm. I then spaced the brake caliper using washers under the mounting bosses to get the disc in the centre of the caliper.

End result perfect, but it always makes me wonder why nobody ever picked it up before.

The speedo on the bike had a cracked glass, so that went off for repair, but otherwise it was complete, ran happily, and passed all its obligatoy head tightenings and valve adjustments as well as receiving an oil and filter change before being collected by the owner.

The T160 is still running great in 2019 and has been trotting around the country to various rallies whilst displaying good manners and excellent reliability.

Rewarding from my perspective.