September 2013

1975 Triumph T160 Trident 750

My friend Gary in Blenheim whose Rocket 3 I had worked on had expanded his British bike habit with the acquisition of a T160 Trident. I first set eyes on it during a visit up thataway in late 2010 when travelling with another mate who was visiting from Perth and had rented a bike locally.

We all rode together at that time and there were a few issues with the T160 that eventually resulted in the bike coming down to me to be sorted.

The bike had come at a fairly premium price as it had been a fairly comprehensive restoration. It looked to be mostly as you would want it, but as it turned out, there were a few issues that caused my first impression of it to lose its gloss as work progressed.

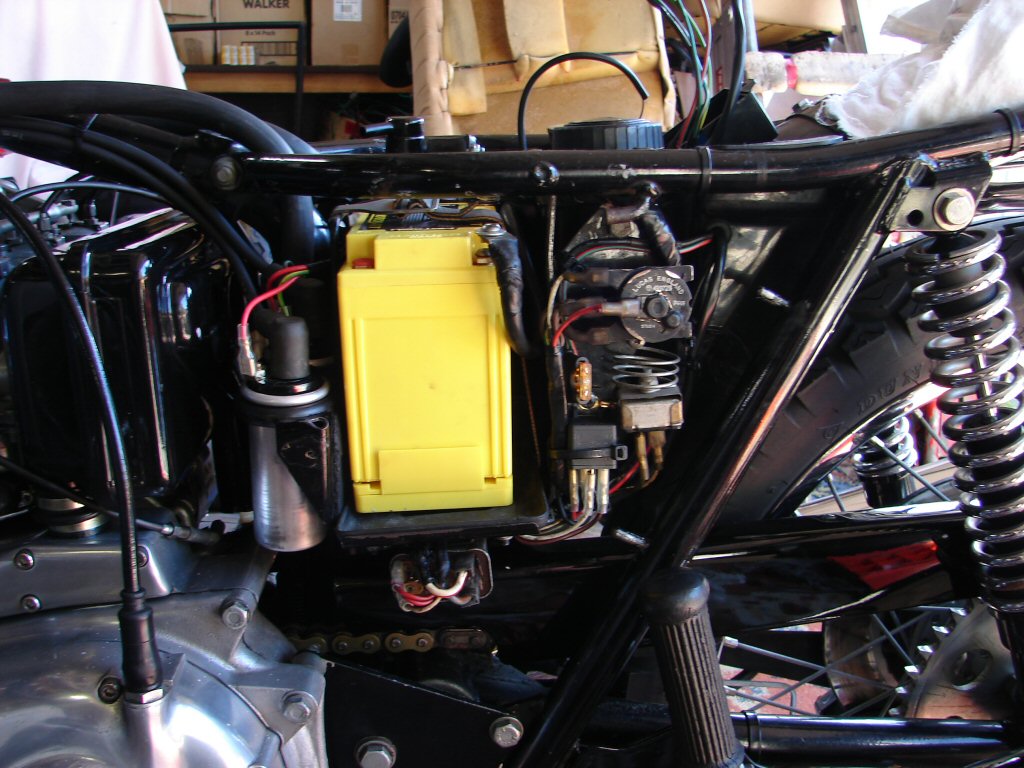

One involved the reluctance of the electric start to function well, as - if you have one - you would rather it worked as expected than not. The immediatey obvious thing I found was that the wiring was not anywhere as good as it should have been.

This bike featured a Boyer electronic ignition system, and they are known to be somewhat picky about how many volts they receive. Despite fitting a new battery, the bike had still refused to fire up on the electric start. I discovered that a number of volts were going missing inbetween the battery and the ignition unit. I found out where..

If you have any appreciation of wiring you will notice that there are a few wires soldered together here that do not look very happy. Or even to be the same colour. This makes troubleshooting rather difficult, and it is only after removing the insulation tape wrapping the loom that such deviant behaviour is revealed. And it was. So I made some changes.

Even with the best intentions, old wiring looms can have trouble conducting current all the way up the front, through various switches, and then down the back where the electronic ignition unit usually has to be mounted - because there are a few spaces back there. Such was the case, and the wiring harness had been unable to supply enough volts to the ignition unit for it to even be bothered performing. Even with a new battery. Mind you - the various weird soldered joints did leave something to be desired. Like sense.

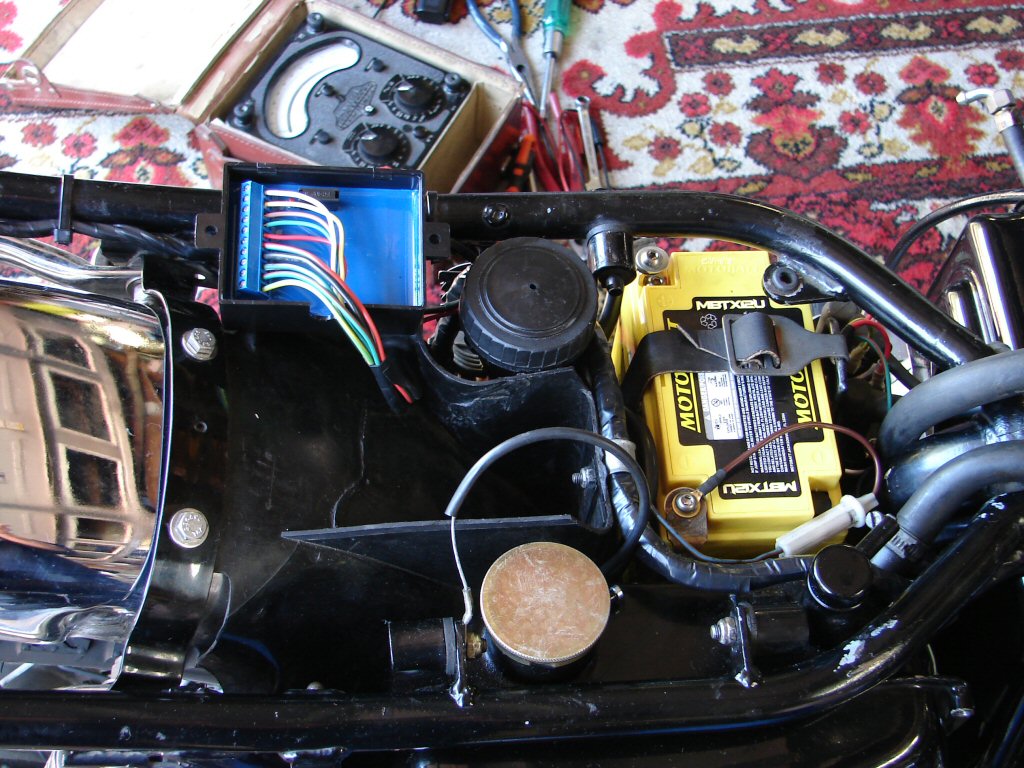

My standard response to this situation, regardless of how the wiring looks, is to fit a relay that allows full battery voltage to reach the ignition. As it happened, the owner had decided that the Boyer was not going to be his best solution, and had supplied a new Trispark electronic ignition system for me to fit. Which I did. With a relay. Mid picture.

Trispark unit was mounted in the original tool area under the seat - which would not require tools if I did this job properly. Here's hoping..

There were however a number of other issues that I had discovered during the work in progress. For example, the oil seal behind the ignition in the timing cover was leaking..

That required plucking the timing cover and fitting a new seal. Did that.

Also, the kickstart lever was resting in the wrong place..

This is simply because the cotter pin has been fitted from the wrong side. Remove, turn around, now looks like this..

Such issues may seem a trifle pedantic, but you must remember that this motorcycle has changed hands for a premium price because it has undergone a "comprehensive" restoration. I can only assume that it has been a comprehensive restoration by someone who has rather small knowledge of this model bike.

But then it got more complicated.

There was a problem with smoke from the exhaust, so that entailed removing the cylinder head to investigate. Turned out a valve stem seal had popped off the guide, so at least the remedy was simple. New head gasket was fitted, plus solid rockerbox gaskets to replace the original type which tend to disintegrate with time and inevitably cause more oil leaks.

Beyond here there was another issue that caught my attention. For some reason, someone had fitted some non-standard o rings in the fork top nuts. From the look it had been done a very long time ago. Age had caused the o rings to distort and swell outside their intended location, which had in turn prevented the fork stanchions from being located in their correct place. This effectively alters the steering head geometry and effects the steering of the bike. Not by a lot, but it simply should not be so.

I put all these things to rights until I was happy that - if it were my bike - I would be satisfied that it was the best it could be. Or so I thought.

When I went to start it up after all was done it took simply ages to flood the carbs. I decided to test the flow from the taps and found that there was bugger all, which is the easiest way to describe it. The answer was the cheap fuel taps whose rubber internals had swollen to the point that very little fuel could get to where it was needed. There have been a few holed pistons thanks to these type taps.

Once running I found that there were a few carb tuning issues and it turned out that there were some non-standard internals. There were richer slides fitted and I surmised that the better flowing Viking Exhaust mufflers may have altered tuning a bit, but trial fitting the correct slides made things worse, so I left them alone and turned my attention to carefully synching the slides and balancing everything to best effect. The results were pleasing.

I was lucky enough to undertake the delivery trip of 200 miles, and the smile did not leave my face for the whole thing. A very sweet example of a better sorted machine with a working electric start.

Whilst I lament the fact that often owners have received less for the purchase price than they should have, and I am most happy to have been an instrument in helping to rectify such a situation. This bike is now the best example of a T160 Trident that I can manage without getting too obsessive.

I consider it a privilege to be involved in such a process.