February 2025

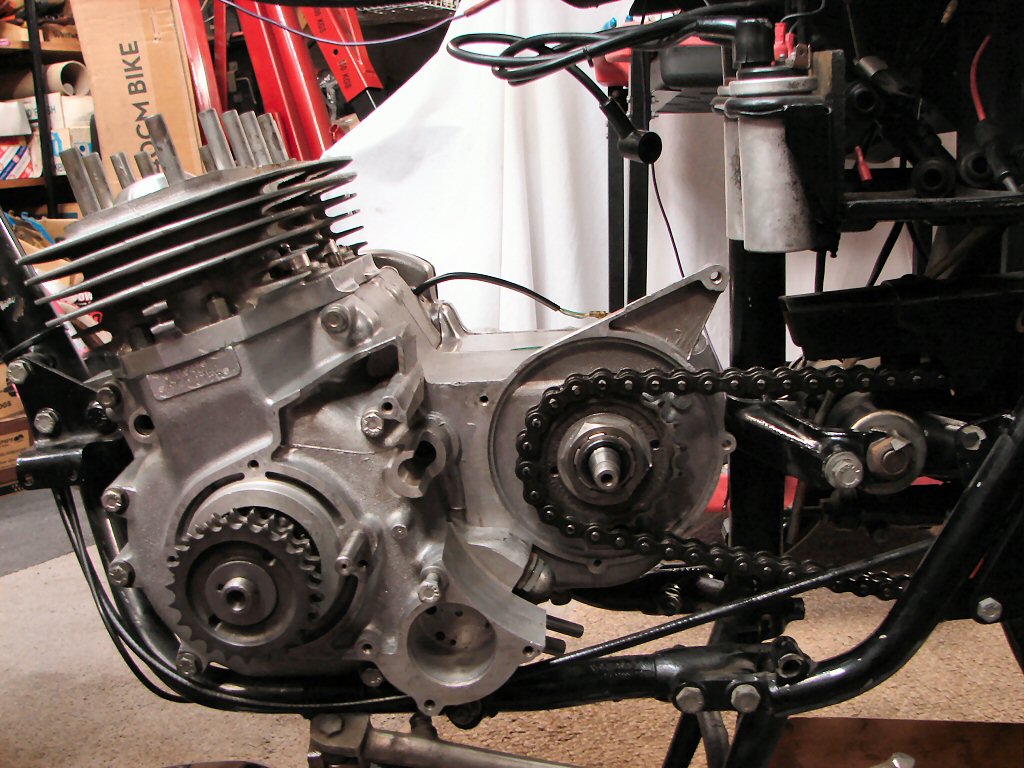

1975 Triumph T160 Trident 1000

The second bike on the transporter was this T160 with engine unit totally removed more than a decade ago, for reasons that are yet to be revealed. I am rather averse to assembling anything that I did not take apart, as that is part of the discovery process, so we will just hope that everything has survived in workable shape.

The fact that the bike has been stored for 15 odd years does not bode well for things like hydraulic brakes, so it is likely that there will be a bit of remedial work involved in restoring some healthy brake cylinders.

Apparently everything is contained within these two hefty storage devices, and from the weight of them I am pretty sure that at least all the major assemblies are there. I shall firstly need to uncover crankshaft, barrels, pistons and rods and the cylinder head and valves, so we can find out what ails the machine to the tune that a total strip was deemed necessary.

To add to the mix, this is a full Hyde 1000cc conversion, with a stroked crank rather than just my 830cc version relying on bigger bores containing pistons for which we might now neeed a set of new rings.

As matters in the shed are pretty diverse at this time I guess I am rather fortunate that at least one more bike is just a rolling frame, as these are far less space consuming than one with all its bits.

I am pretty happy to have such tasty machines visit of course, although I feared that I would not have enough room to work on them unless I moved a couple outside while work took place. Happily I was wrong, and can still operate indoors. albeit in a rather careful fashion.

Well - the contents of the bins is like aladdins cave, with everything carefully wrapped and super clean, so many of my concerns have evaporated. Brilliant work by the owner.!

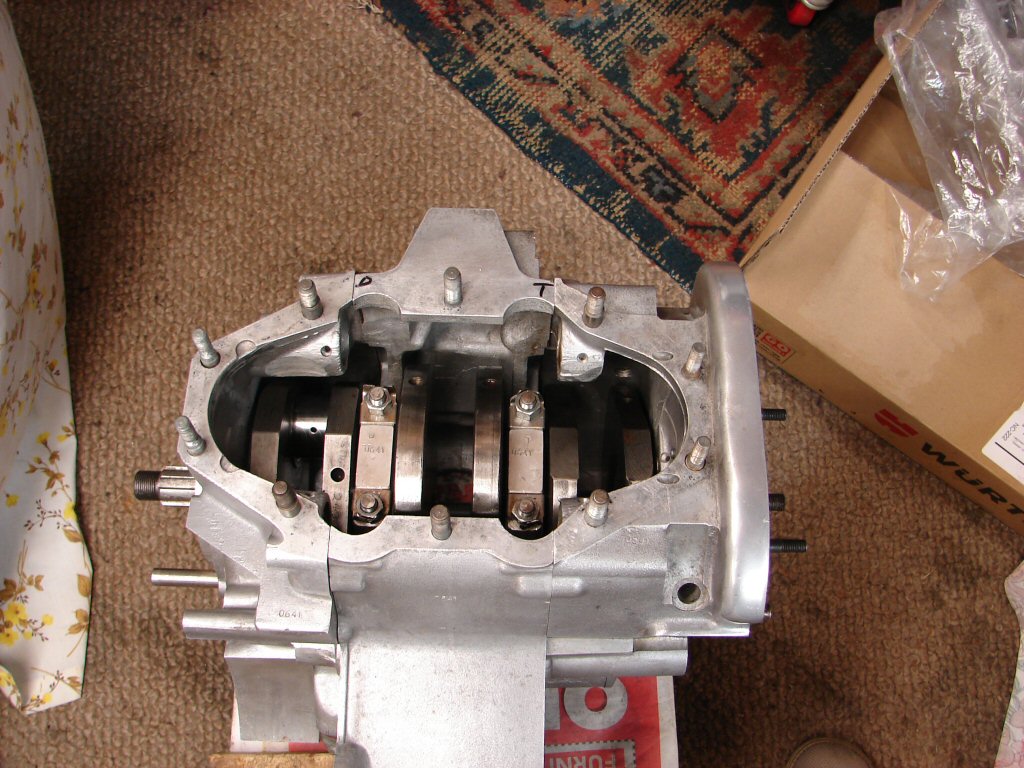

I found the crankshaft lurking in the bottom of the heaviest bin, and other than a few scratches on the journals it looks to be fairly intact. Hard to tell how much the big ends have been offset, but it all looks very nicely machined and may have even lost a little weight.

I doubt that there would be any reason why the journal sizes would differ from stock, so there should not be any trouble sourcing new bearings for it, but we will have to ascertain whether or not the crank needs grinding to undersize or will respond to just a thorough polish.

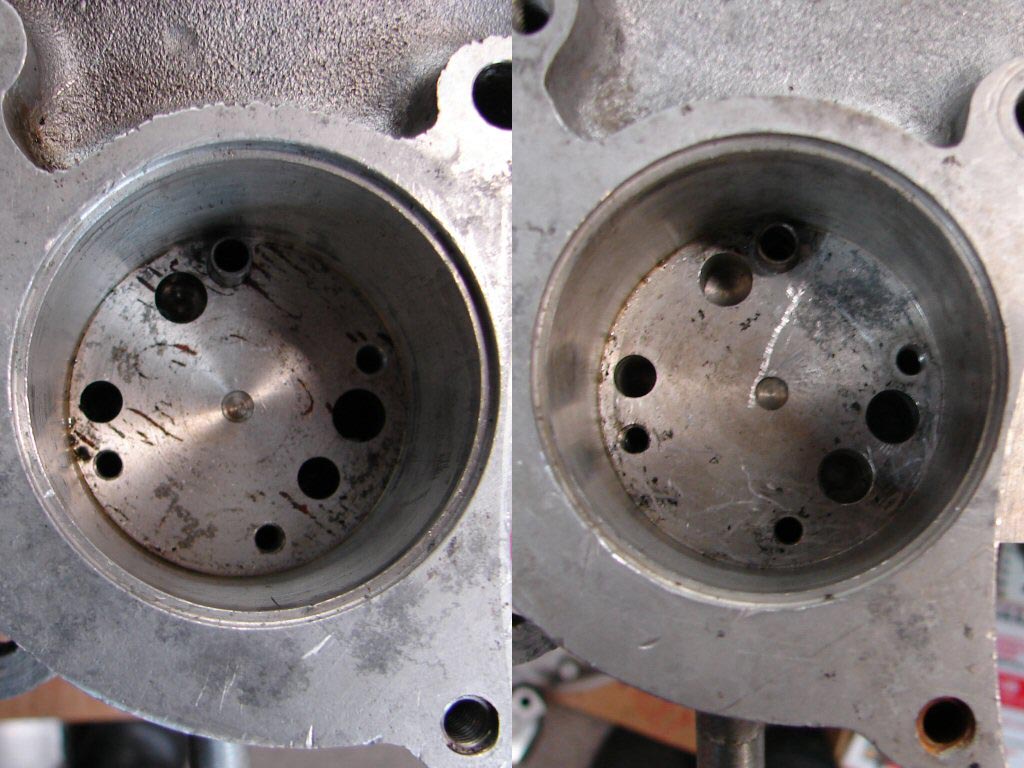

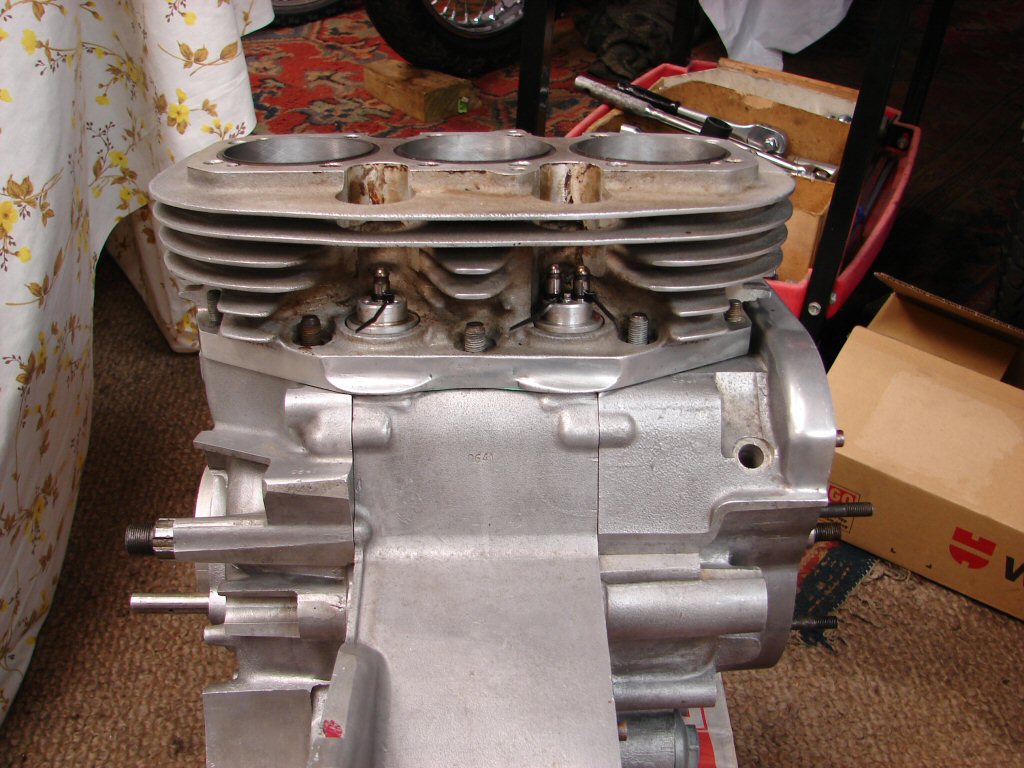

The barrels look to be in very good condition also, perhaps a bit of a glaze in the bore needing a hone, but what we can find in the way of rings that will nullify the triples potential for an unhealthy oil appetite remains to be seen - or found.

The cam followers have seen some miles, but are good enough for another tour of duty with a good clean up. Camshafts are yet to be sighted but will hopefully be in similar condition.

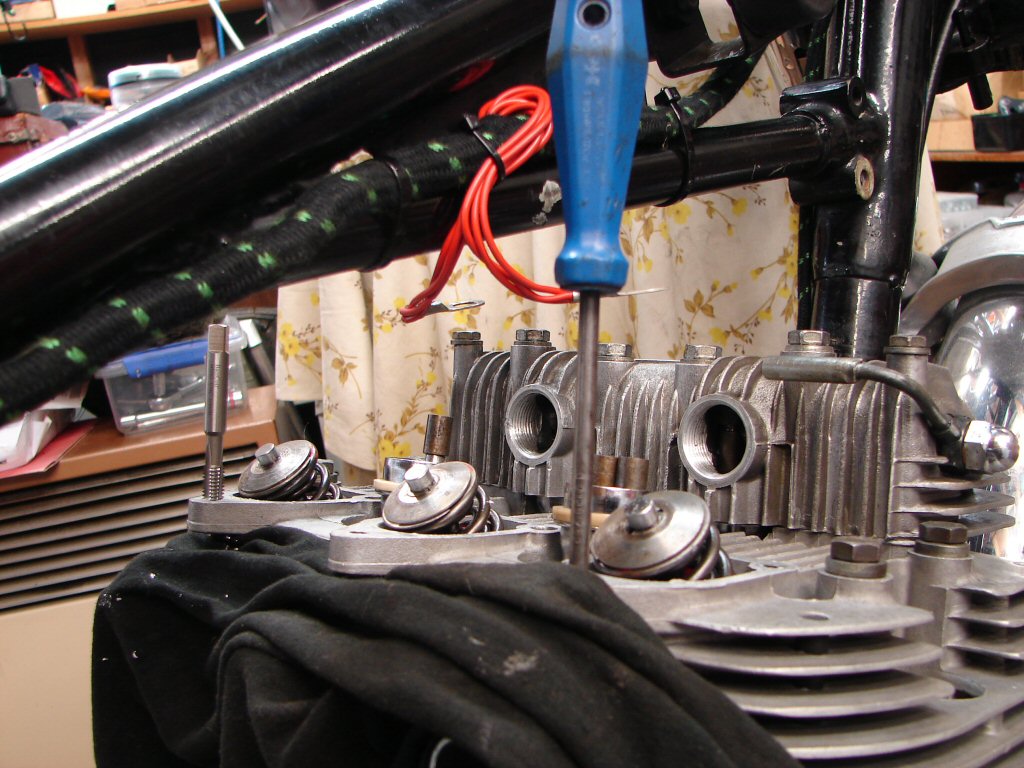

And then the head.

I virtually never find a head with valves and guides this good. Usually they are obviously worn to their limit, and guilty of causing most of the problems that the bike has come in to have repaired.

The inlet guides are non-original and designed to have seals fitted, although there are none present. I prefer to use standard type guides like the exhaust valves feature here, as they at least allow enough oil down the stems to avoid rapid wear. I guess the bike is hardly likely to see the sort of mileage in future that would warrant changing them if they don't need it, but it would be prudent to find some seals rather than leave it to chance.

Pretty big holes down them inlet tracts, and I believe there are Mikuni carbs attached to them, so it should be quite a serious performer when going as it should.

While I have yet to sight pistons, rods and camshafts, I have not found any reason why this engine needed to be torn down as of yet. That bodes well for a fairly hassle-free rebuild as long as we can source whatever parts are Hyde specific.

After a fair bit of unwrapping I found the next important parts of the puzzle. I also found a reason for at least a top end strip, although I am not sure that the problem would have been apparent until it was in pieces.

Checking the newly uncovered camshafts I found one rather badly chewed lobe on the exhaust cam, and then found the offending cam follower which echoed the problem.

While cam followers are available locally, camshafts are pretty scarce worldwide, especially T160. As it happens, I have a pair of new old stock T160 camshafts that Les Williams supplied when I built my Hyde 830 back in 1991. My original cams were in such good condition that I left them in place, so these were just valuable spares.

I guess it means we are covered, but my first course of action will be to see if Kelfords are able to build the lobe up and re-profile it. I shall follow that up tomorrow after dropping the crank and barrels off for Glen to give his advice on our best course of action.

The pistons also came to light, and look to be in good enough shape at a glance. They are also a very firm fit in the bores, so as I had hoped, a hone and a new set of rings could be a lasting fix. Sourcing the rings will now be the tricky bit, as T120 Bonnevilles were a lot easier on oil rings, but Glen may have some input on the matter.

Those pistons are 71mm and I likely have the very same in my bike, which is probably well on the way to also needing a set of rings after 25000 miles of my fun, so we shall see what some of the owners forums have to say on the subject.

Finally, at the bottom of the bin, I found the conrods.!

Well well. From the profile I am picking that these steel rods are carillos, so we need lose no sleep over their life expectancy. They also contained some fairly good bearing shells, so I now know the journals are -10 on the bigends. The mains I cannot tell as they have markings that do not show up in any search results. No doubt Glen's micrometer will provide the answers we need in quick time.

I will also need to research the torque figures for the big end caps, as from memory they use at least double the tension of the original alloy rods. Thats two wins and one lose today.

I think thats a major win overall. I have even ordered a new cam follower and some main bearings - get 'em while they're hot.!

Well - the game can turn around quickly.

There was a bad score in the centre bore, which was explained by the failure of the piston. On both sides above the gudgeon pin the alloy had broken away beneath the oil ring, and no doubt the resulting debris was responsible for various scratch marks on the bearings and journals. A little bit of grit goes a long way.

We now have two puzzles to solve. Will the bore clean up within the max oversize pistons we can acquire, and what pistons may they be. While Norman Hyde do stock oversize pistons for the 1000cc engine, I am reeling at the 600 pounds asking price for what are basically T120/TR6 pistons available locally for $270 a pair. Problem is - will their oil rings satisfy a Triple.

They would also need their skirts machined to match the current items as I figure that is a necessary crankshaft clearance requisite.

On another front, the oil feed to the crankcase is still the early 5/16" pipe, rather than the later 3/8" version, and when you are this far into the engine it would be foolish not to uprate it. We do have some signs of premature wear after all, so more lube is a sensible move.

But there is a win. On Glen's advice I dropped into a camshaft shop nearby his workshop, and am very pleased that they are indeed able to rebuild the one damaged lobe within a few weeks. I was also impressed with the two chaps who run the place, as they were both pleasant to deal with and knew their stuff.

So many of these skilled people have thrown in the towel of recent years that it is a rare thing to find some more experienced people still supplying these services. Long may it last.

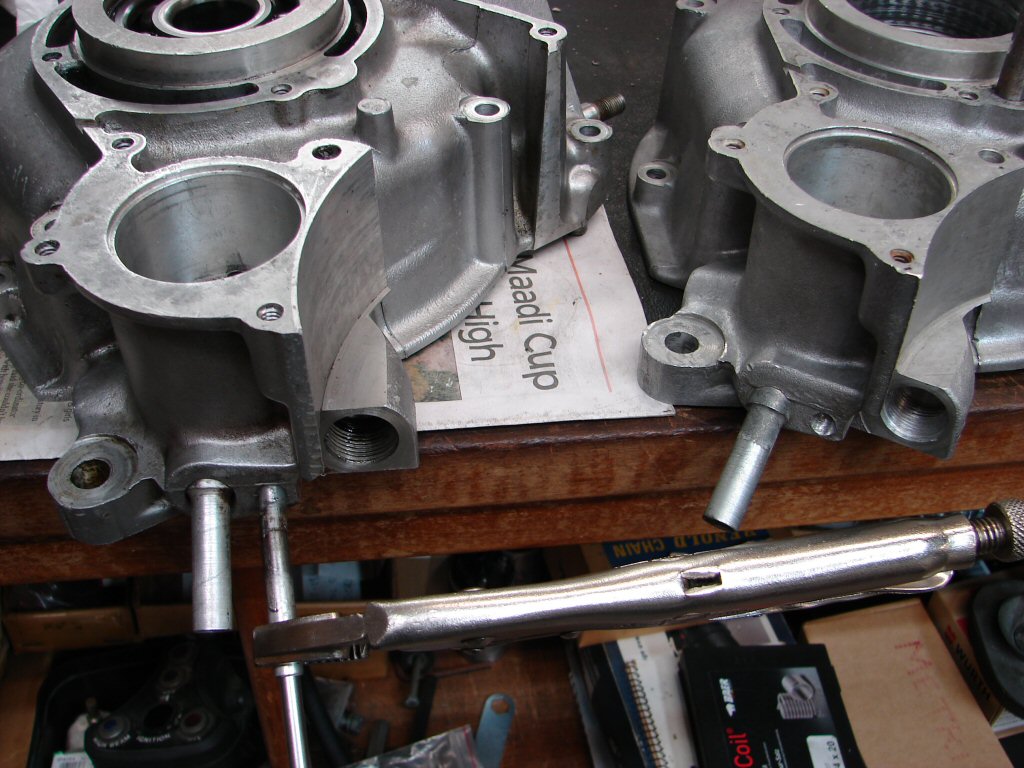

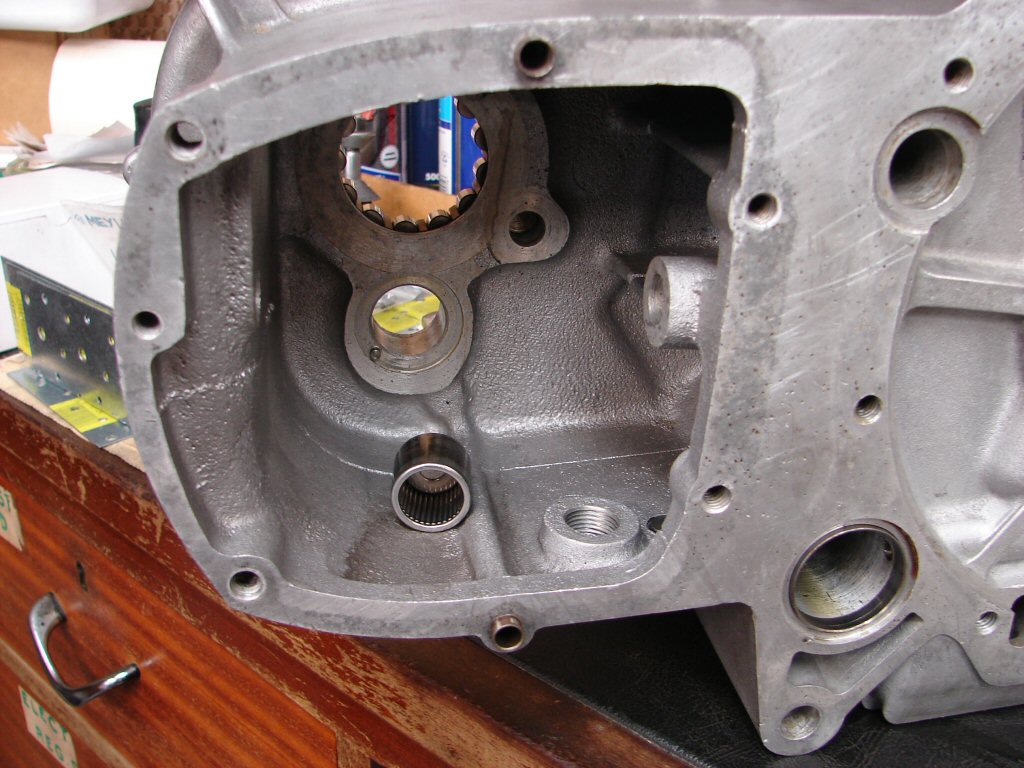

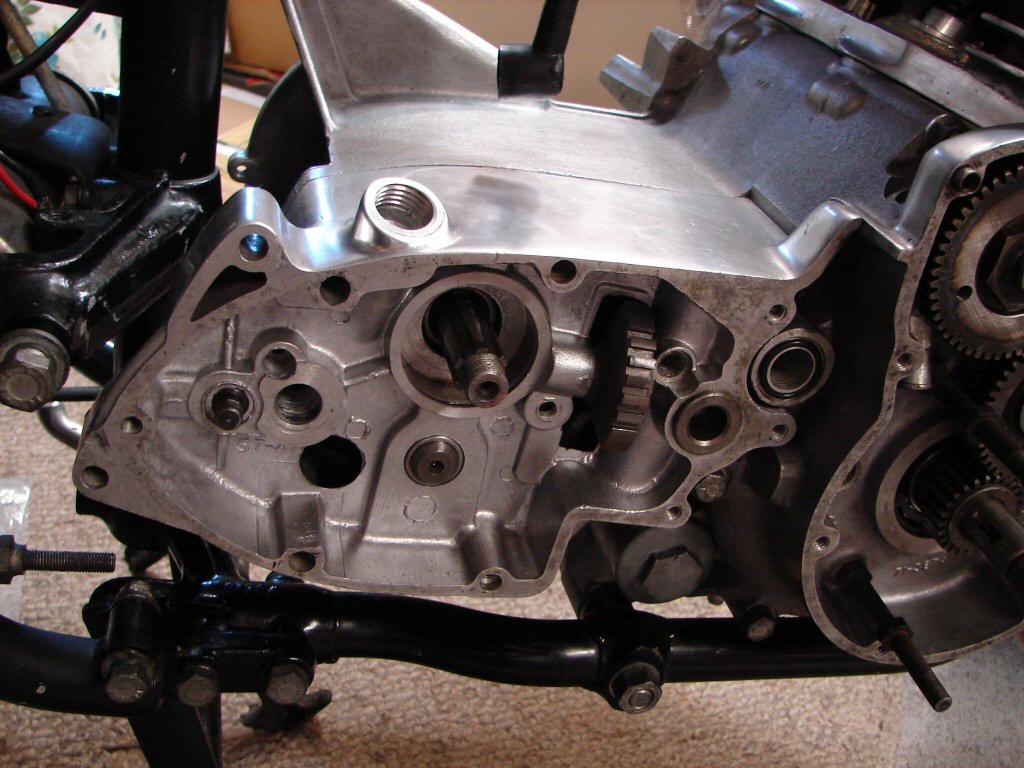

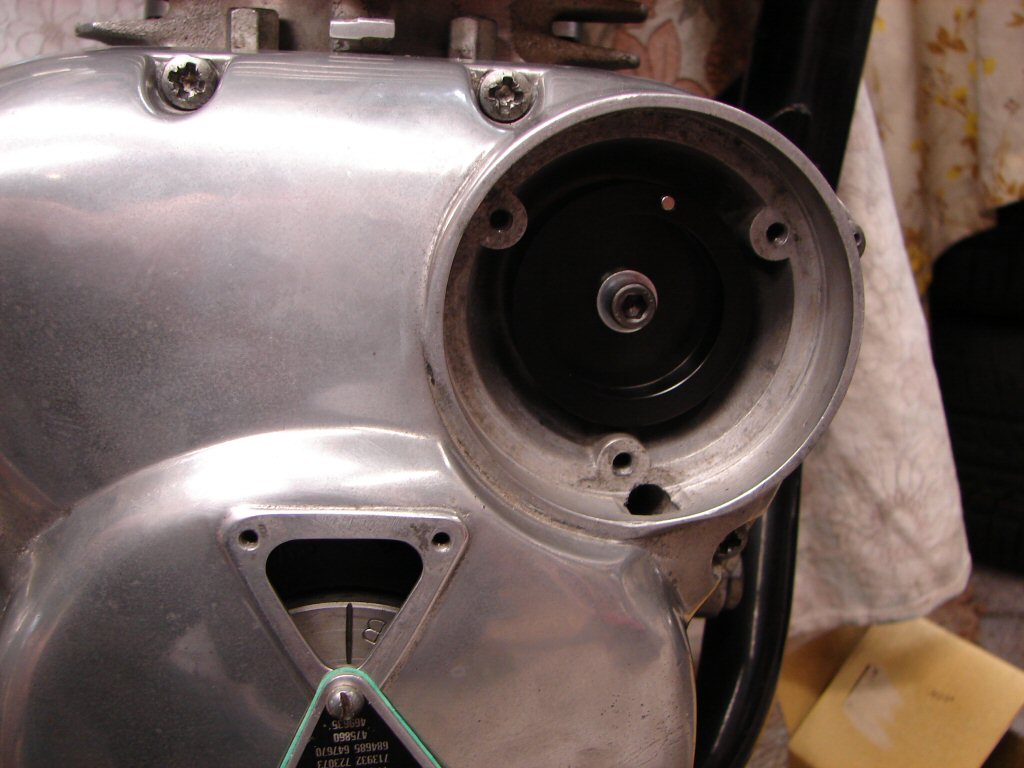

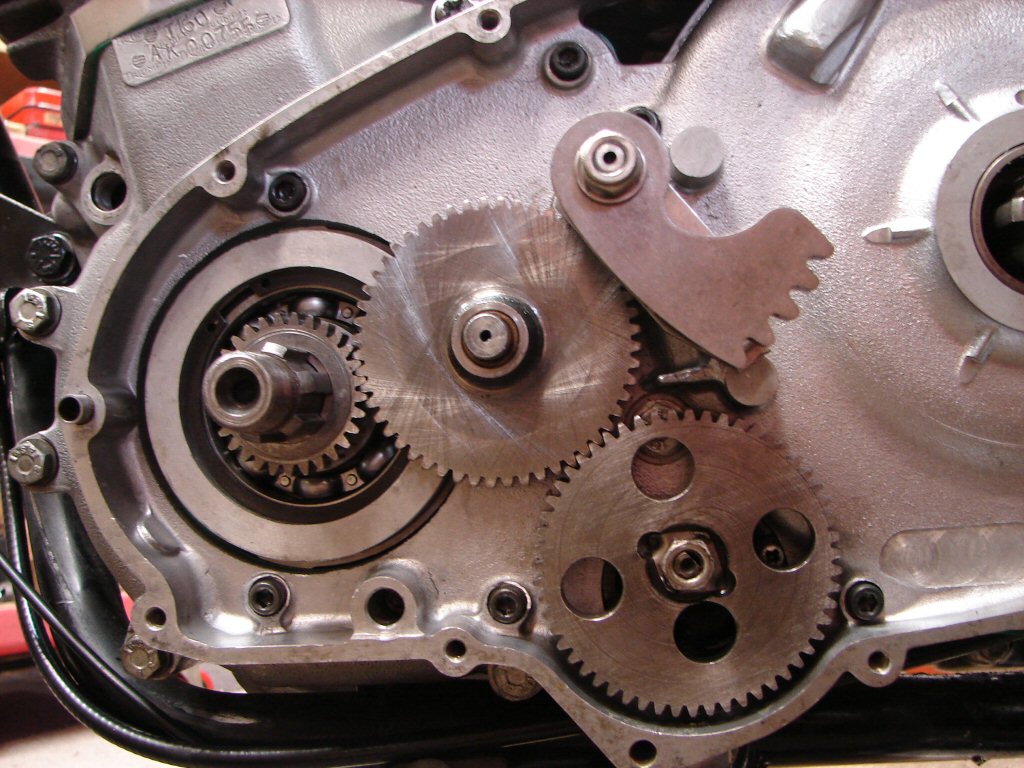

As I was preparing another oil feed uprate I did them both together, removing the pipe and drilling the oil passages out to 5/16" which is the inside diameter of the new 3/8" pipe. This involves drilling in two directions - one where the new pipe will fit and the other into the back of the oil pump cavity. This one is on the right, all ready to go.

The hole at about 4 o clock is the one that leads to the oil tank, and yet the two larger holes are those whose job it is to handle the outputs from both sides of the pump - one to feed the engine and the other to return all the used oil back to the tank. You would have thought that they might have spotted the crease in the plans a bit earlier in production, that enough oil has to come through that smaller hole to be delivered to the vital parts of the engine through a larger one, no.?

While it is not earth shattering, it is easy to spot the obvious increase of diameter in the second pic. Once you have been here you would never leave this setup as-is if the engine was being stripped this far. I have another T160 in the shed whose engine is not being stripped, and yet I am tempted to do so just for the benefit this mod provides.

It goes without saying that the corresponding hole in the oil pump backplate will get the same treatment.

With all the major bits away for attention it has been time to find all the small bits that are equally important in the grand scheme of things. Like handlebar controls.

The brake master cylinder is hopefully ready to move fluid when commissioned, and the other parts are finding their best locations. I am not sure if the left side handgrip is partially off or if the clutch lever needs to move outboard a little, but as it seems a mirror image of how the right side is set up it may have been deliberate placement to get the levers positioned to best suit the rider so I shall leave it like that.

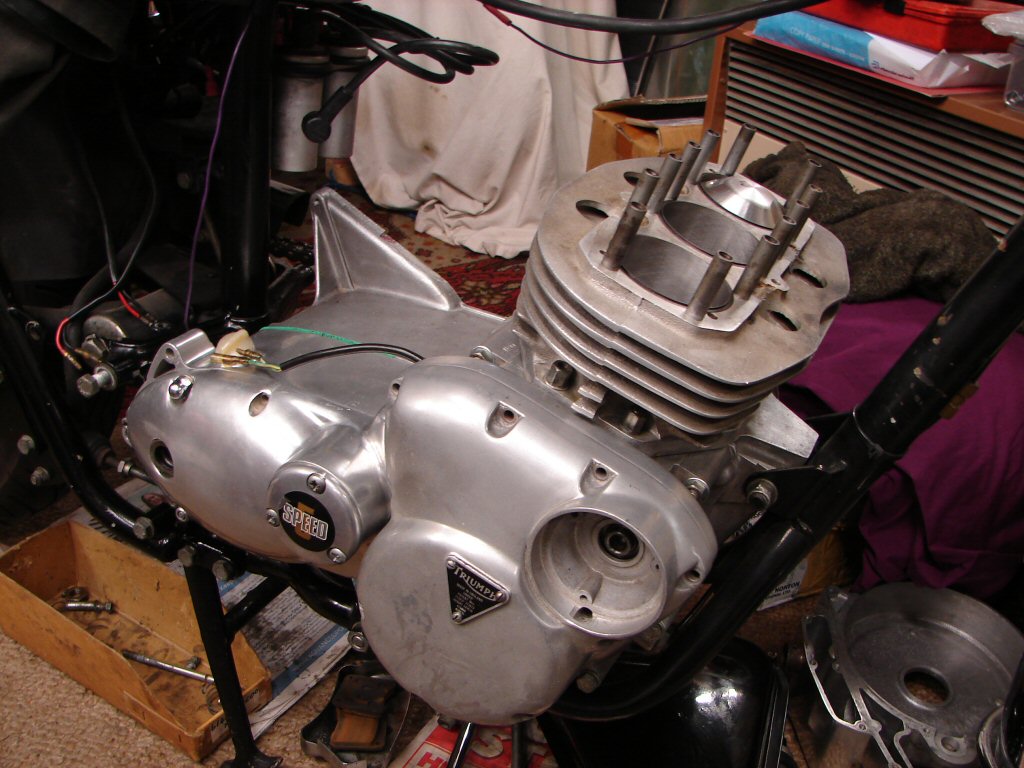

Finally - something has returned from one of the outsources over whose timetable we have no control. I hope this marks the end of the drought.

The exhaust camshaft is back and they were pleased with the overall result. Apparently the cams were originally nitrided which makes the building up process more difficult, but these guys are used to such obstacles so they were only informing me of info I am not familiar with.

At less than half the cost of a replacement camshaft and with zero freight this was a real bonus as far as overall costs go. Soon to be united with its new follower.

Many moons passed while Glen was suffering staff shortages, so I set about finding as many anticipated parts as I could to fill the time. There had been some odd main bearing shells in place which certainly needed replacement, but these were unlike any I had previously encountered. I had wondered if the size of the journals had been uprated during the Hyde conversion, although the big ends were of standard dimensions and already .010 undersize. Glen finally identified the main shells as being from a crossflow Ford, and they had been fitted due to the crankcases having been line bored. I would see that as being a very wise move due to the average quality control of the time, and the added need for accuracy with becoming a 1000cc powerplant and the expected extra loading this would produce.

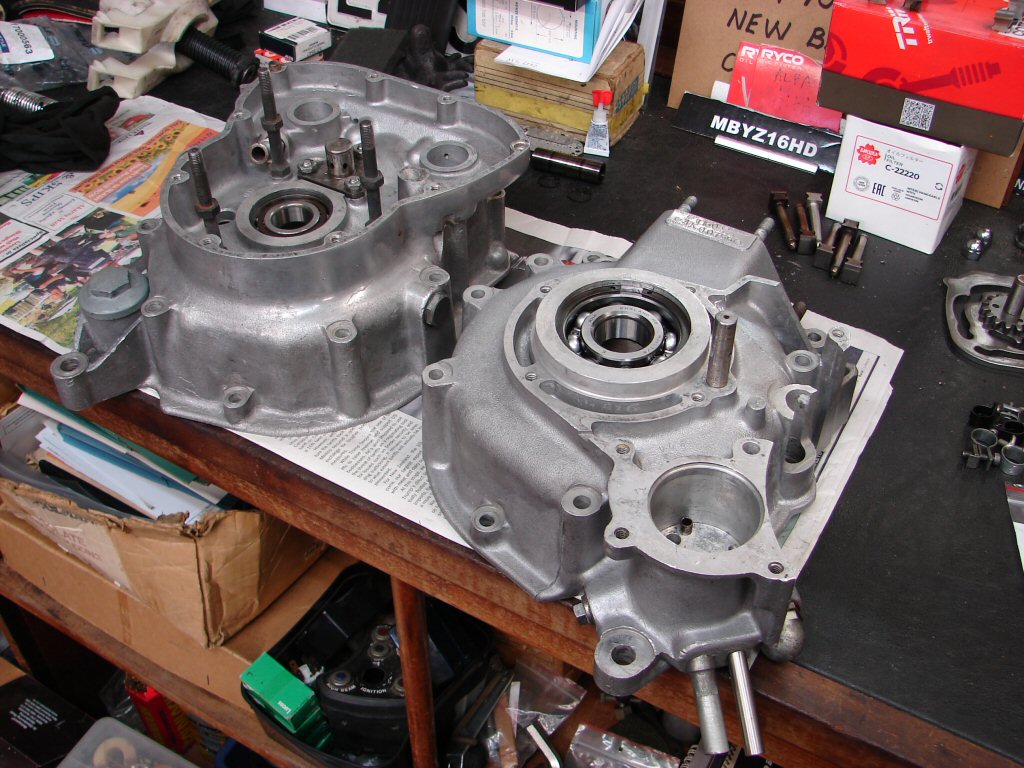

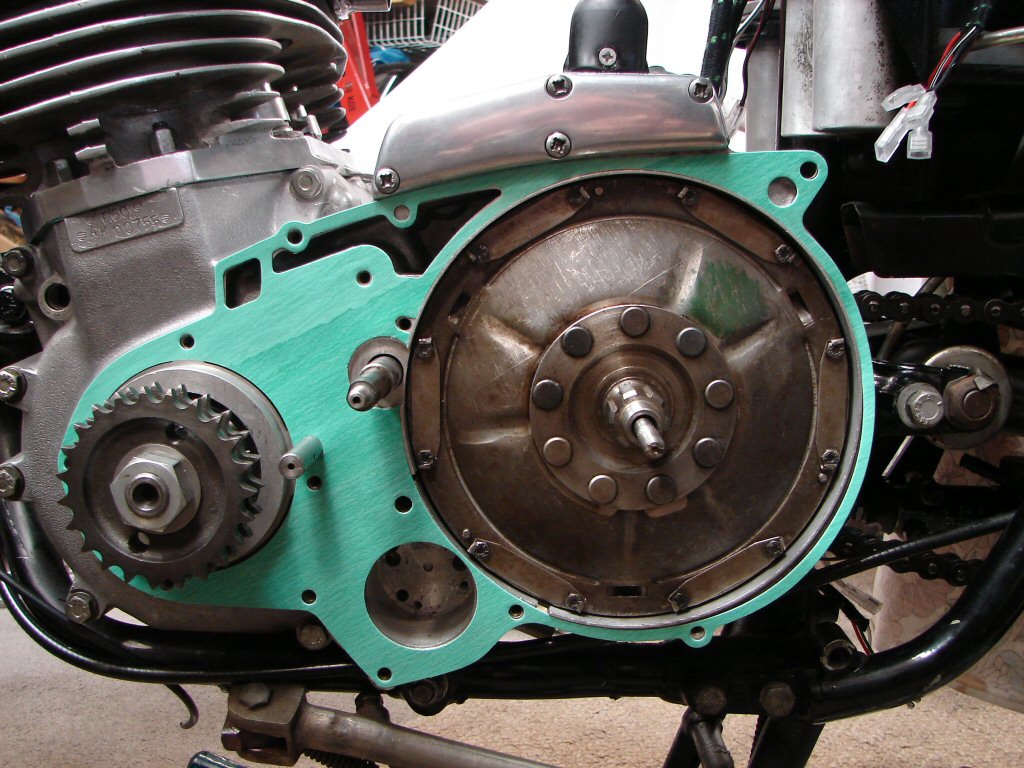

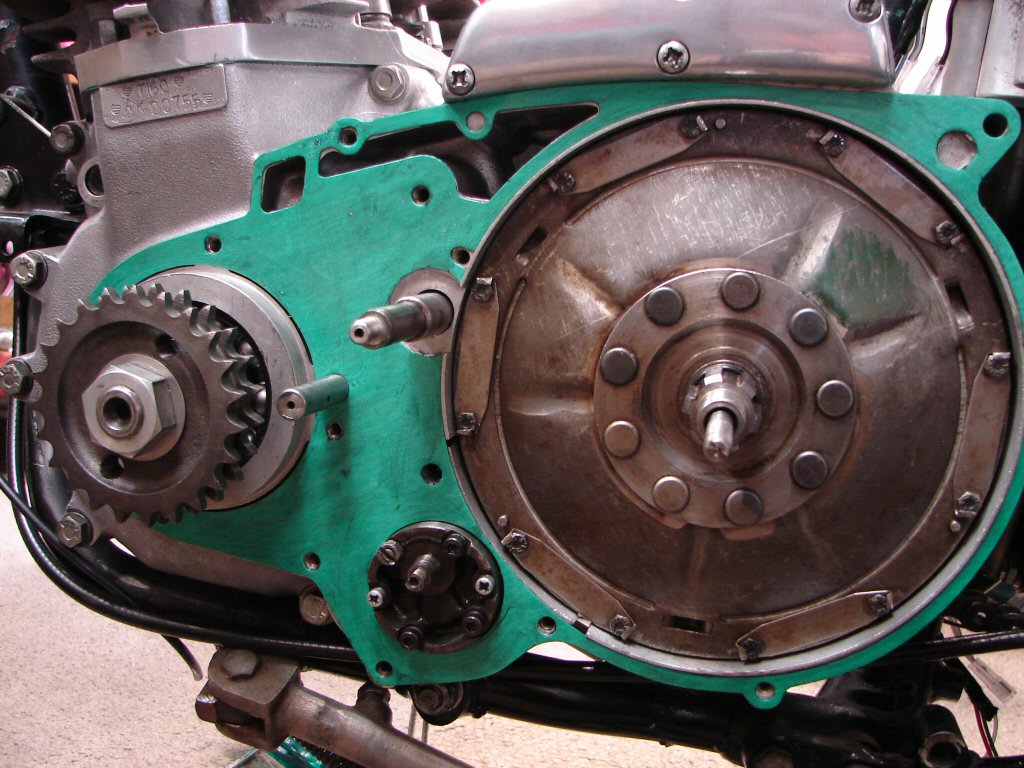

Glen thinks he is able to obtain new shells for the mains and I have some NOS copper/lead big ends, so we are back in the game. The first major piece to come home was the drive side outer crankcase, complete with its uprated oil feed pipe, so both outers got cleaned up, threads cleaned and new outer main bearings installed.

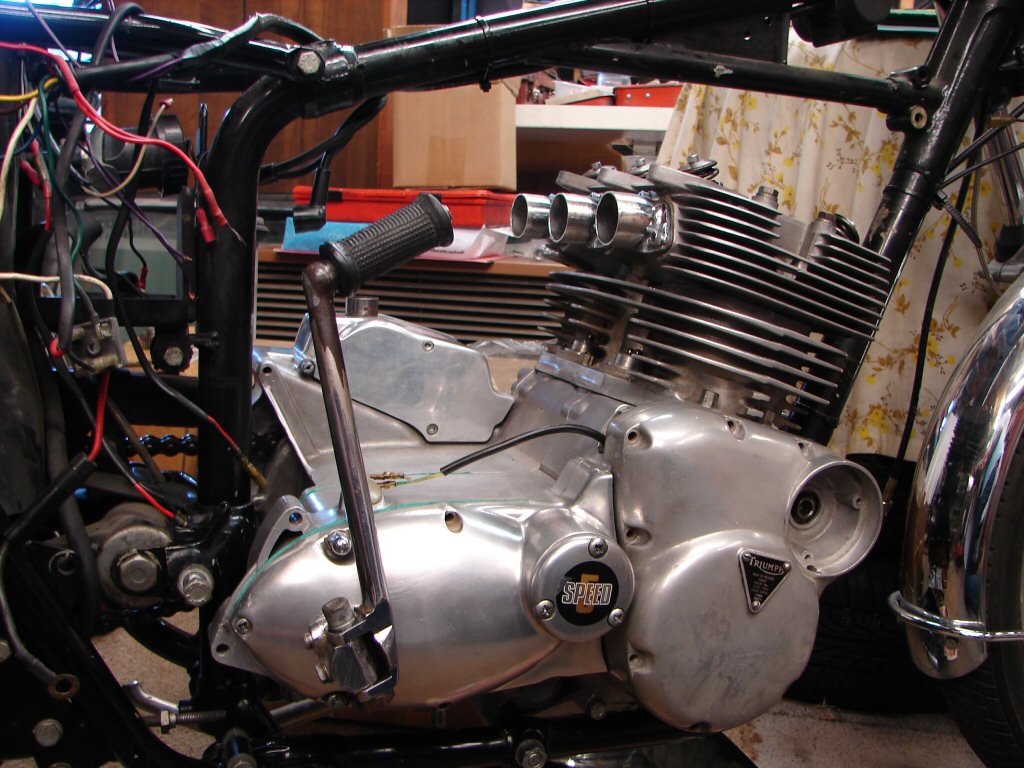

I am over the moon to be assembling this engine at last.

Next will be the centre case, crank and rods, which after cleaning can be bolted together and the reassembly of the complete bottom end begins.

The new pistons have arrived in the form of two sets of two, as they are T120 type and sold in pairs. These are for 71mm bore and are thus probably the same as my Hyde which is 830cc using the standard stroke.

These pistons will need their skirts machined to create enough clearance to clear the crankshaft webs when at BDC.

I was suspicious of the failure of the original Hyde piston in this engine, as it seemed very thin below the oil ring where it collapsed. It appeared to have been machined to accept the 3 piece oil rings that were in use.

These pistons look definitely beefier below the oil ring groove and I am confident that the cast oil rings they supply actually do their job well thanks to the expander which fits inside them.

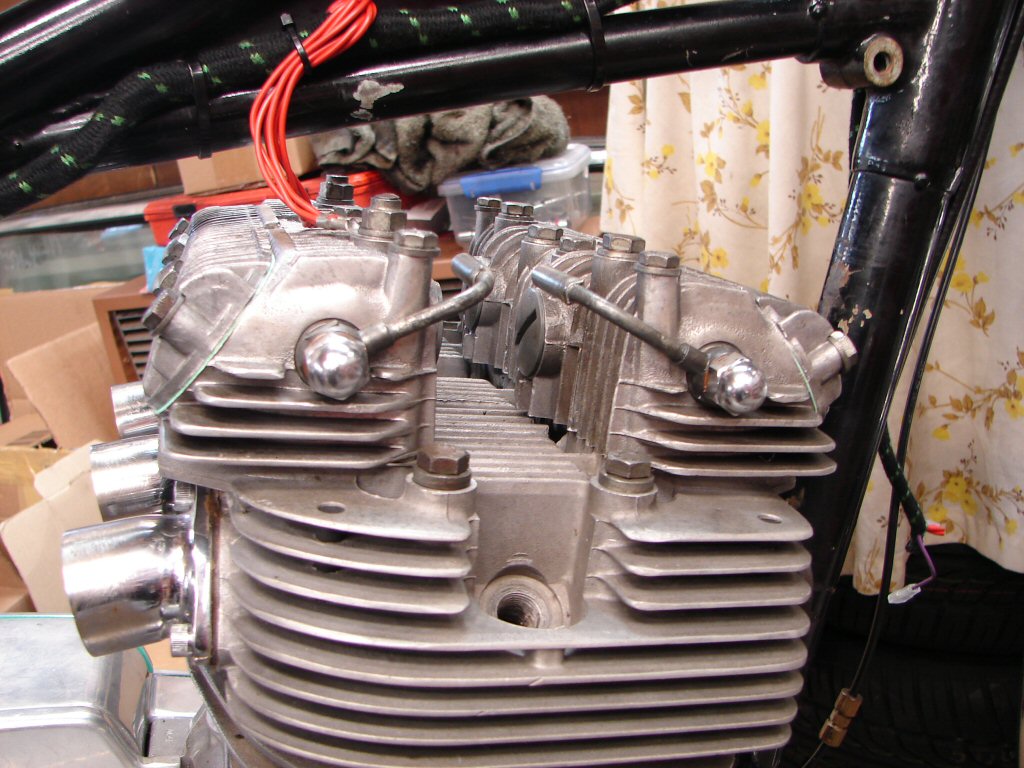

And today - it all came home.

Whoopee.!

Time to start moving this thing along.

Glen made a nice job of imitating the skirt profile needed to give clearance to the crankshaft web. We also have 1 spare which will hopefully never be needed, but would save huge effort if ever it was.

Pleasing to note that even the skirt thickness is beefier on the Hepolite items, and there is approx twice the distance between the oil ring groove and the gudgeon pin recess. I would have to suspect that the original pistons were always going to fail in the way one did, it was only a matter of when.

Having to now troll through all the boxes and bags full of parts the engine arrived in, finding certain small bits is going to dictate which things get assembled first, such as the head.

Apart from the centre exhaust manifold, here it is complete along with its new red inlet stem seals. Glen does a brilliant job of valve and seat prep and they are a joy to put together.

Because the inlets are 35mm for some matching Mikunis there are no gaskets with which to replace those in place between inlet stubs and head, but I shall inspect them for integrity and possibly add a smear of silicone if necessary.

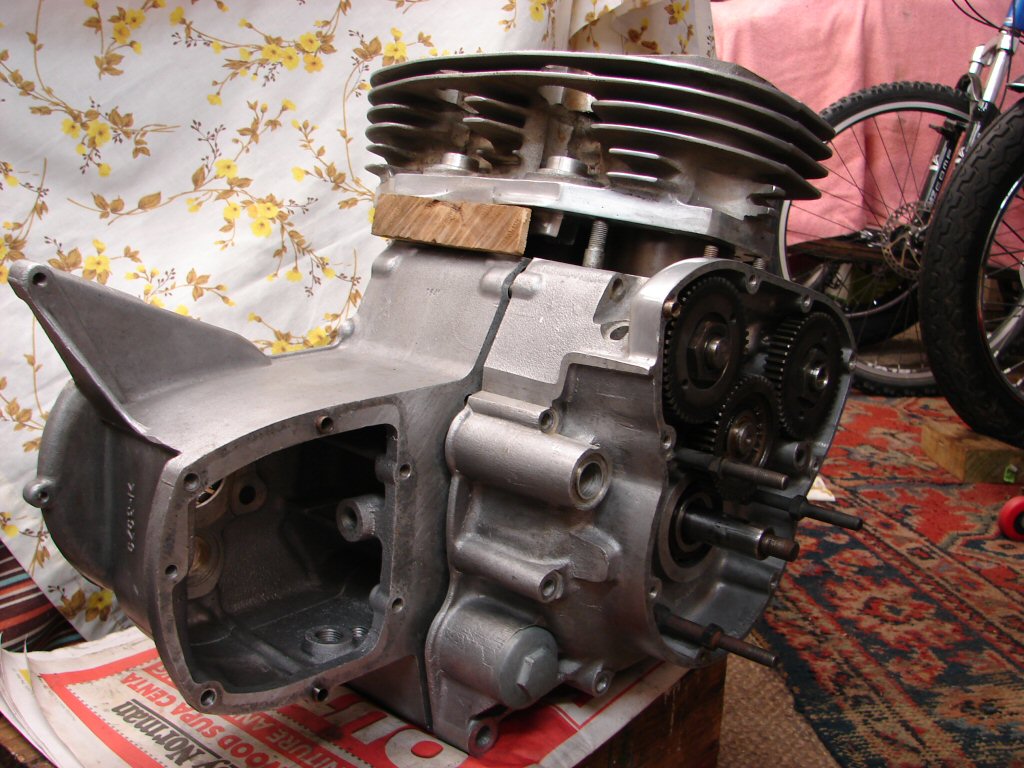

Next step is to trial fit crank and block to ensure that it is possible to assemble the engine in my preferred fashion due to the liners being of greater dimension. Especially considering the degree of extra effort needed to compress the current style of oil rings, this method makes everything very controllable and as stress-free as it could possibly be, which is a necessary consideration for those who work alone as I do.

It allows the pistons to all be fitted from the top of the bores, meaning ring compressors can be used easily. As the extra conrod travel of the stroked crank requires cutouts in the bottom of the liners it would be very difficult to try dropping the barrels over the pistons, and far more likely to result in fracturing these brittle rings.

The good news is - it works - the camshafts are able to pass through the centre case with no clearance issues, so we can proceed as planned.

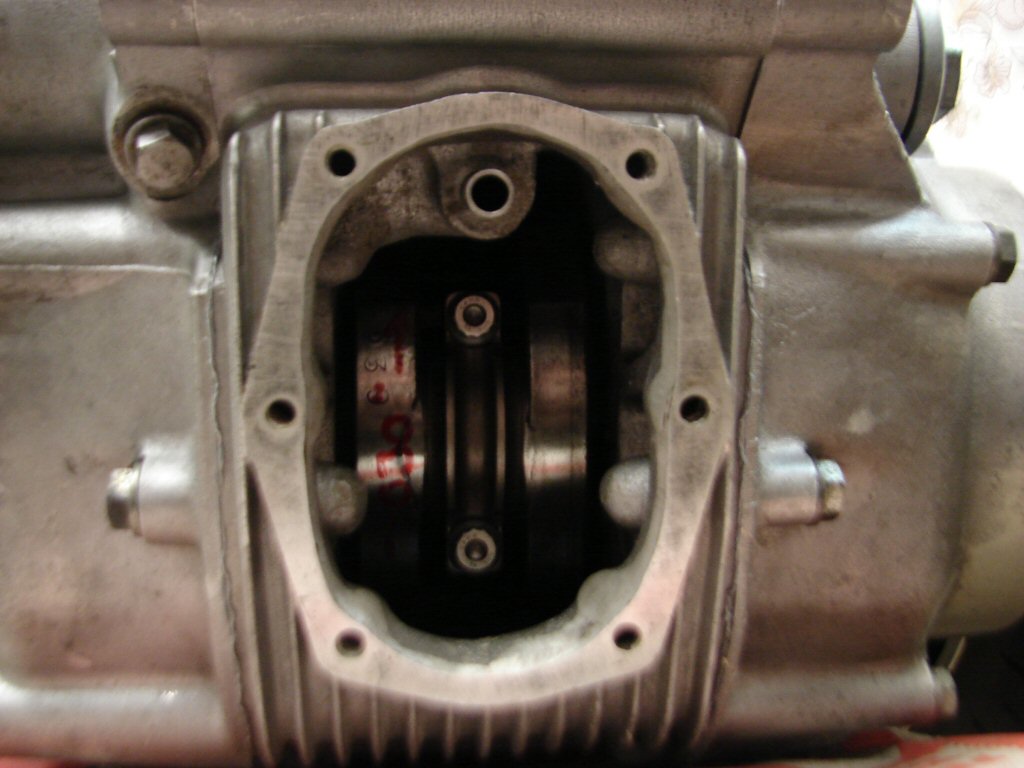

Usually having got to this stage I would continue finalising the torquing of main bearing caps as the crank would not be needing to come out again. Unfortunately whoever stripped the bike 15+ years ago had decided in their infinite wisdom to remove the gearbox layshaft blind needle roller bearing from the left side of the centre crankcase. I realised after I actually found the old bearing that the case would have to be heated in order to get a bearing back in there, and this would entail pouring boiling water inside the gearbox housing, so working with a crank sticking out the sides was not an option.

I inspected the end of the layshaft which had been running in the old bearing, and it is perfectly unmarked. Why pull it out then methinks.? I have inspected it carefully and there is no reason why I would not put it back in. It is definitely tight enough in the case that it will need heating to coax it in, so there is no obvious problem that I can see which justified its removal. Needle roller bearings in gearbox and primary drive of these bikes do serious miles without complaint, especially when they have adequate oil supplied, which these obviously do, considering how low down the case its home is. This is also why it is a blind bearing - so oil does not leak through it - and yet despite being a press fit the workshop manual also advises filling the slight recess on the outer side with serious sealant after fitment is complete, to be sure to be sure.

Today did not lend itself to setting up outside to heat cases and bash things, so instead I gapped all the rings and fitted them to the pistons, and then fitted pistons to rods, so now they sit as you see them here. These pistons do not have a 'front', as the valve cutaways are identical and the pistons are symmetrical, so I just fitted them with their part numbers all facing the same way.

The cam followers are all carefully fitted where they came from, except the new one which has only just joined the team. I retain them with cable ties, and these can be slid far enough to allow good oiling of everything before the block goes on the cases. I will also need to use sealant to hold the base gasket in place while the cunning plan proceeds, so that will get done soon and left overnight.

The pillar stud holes on the cylinder needed a lot of cleaning and a bit of remedial countersinking, as alloy had pulled upwards around the threads on a few, and you can't afford not to have everything working to best advantage either side of the head gaskets on these engines. As this one has a special copper gasket to clear the larger bores, it got annealed and will be cleaned up and reused with copper gasket spray coatings both sides when assembled. This is standard format for me, and only one engine has ever failed disgracefully to stop leaking oil until a special 'Cometic' composite gasket was used. There had been some damage done to the mating surfaces, and I was not prepared to pull the barrels off just for surfacing when this other gasket could do the job. Otherwise, always copper for me.

Weather was permitting so the outdoor op proceeded with all caution. I seldom find that boiling water is not enough heat for these bearing insertion/removal jobs, and thankfully today was no exception. Not that it just slid in, but with a neat fitting socket and extension it only took a minimum of persuasion to make it comply. I was also lucky to find amongst a bin of useful things that I had a suitable sized plug to prevent water going into the gearbox output roller bearing.

The finesse here is that the bearing should end up being between .073" and .078" proud of the housing when finished, so I opted for .075" and was able to get exactly that. The thrust washer sits around the outer edge of the bearing and slghtly proud of it, and all that worked out in fine style. Not sure why I give these operations a lot more focus than some of the seemingly more critical areas, but these can be the small things that end up causing a lot of grief when things refuse to assemble neatly.

Most pleased with the outcome.

Having dried it all off I was now able to fit the cranshaft into the centre case as a final fit. The centre mains only tighten to 18ft.lb which seems rather modest, but even though the caps are quite substantial they are only alloy, so there is the reason.

Last part is to fold the locking tabs against the flats of the nuts, wherever they came to rest, which gives one confidence that nothing can make a break for freedom somewhere down the track.

All sweet.

The plan from here was going to be to trial fit the outer cases to the centre, so that the cylinder base gasket could be fitted and trimmed as necessary before adhering it to the block and leaving it perched for 12 hours or so, but for no apparent reason I could not get the two outer cases to mate up. It seemed that there was a problem with the camshafts not wanting to fit within their confined limits, so I decided to remove them from the equation as they were not needed yet.

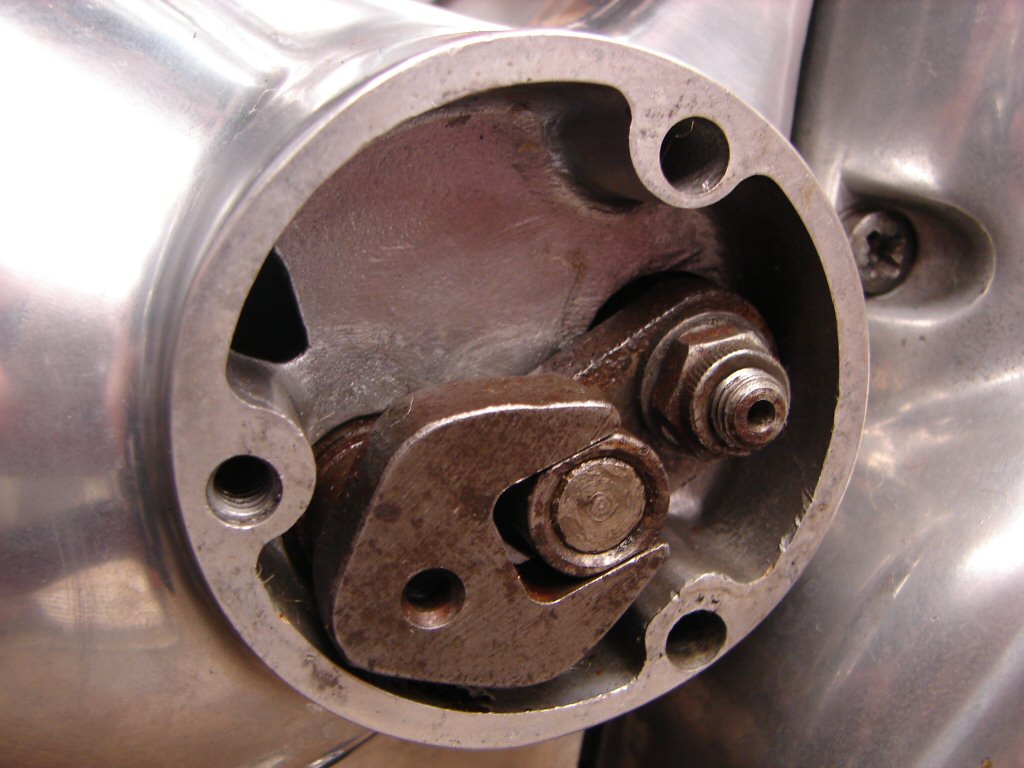

That led to the discovery of an issue with the threaded insert on the far end of the exhaust cam whose purpose is to mesh with the tacho drive gearbox input. It had been damaged in some way and was not threading far enough inside the cam. I screwed it out most of its length to see what ailed it.

This did...

Hard to imagine what had disagreed with it, but something had. I inspected the tacho drive, but it was seemingly uneffected and turned freely enough. I wondered if this threaded insert may be a separate part number, or if it was supplied as an integral part of the exhaust camshaft. The parts manual does not show it at all, but it is a T160 specific part as all earlier triples had the tacho drive in the front of the centre case.

I figured the answer in this instance would be some careful repair of what we had, but meantime I wanted to carry on with the base gasket, so the cases got mated up easily on second attempt.

I am always careful to ensure everything passes the acid test before committing to an assembly, but as this engine arrived in parts I am being 1 step more cautious so that I don't get caught out by some issue I have not yet identified, having missed the disassembly process.

One such issue was of course the base gasket itself. We are using a standard T160 gasket set, but barrels with bigger bores and odd replacement studs do not accept the standard base gasket, so some quite careful trimming and opening up of holes was necessary before the gasket would sit easily on the crankcases and the barrels. Once it did I applied a thin even smear of silicone to the top side and fitted it to the barrels. The resulting mix was then dropped onto the crankcases and all convinced to sit down and behave.

Which it did.

So that halts play until tomorrow as far as the crankcases go, so to make use of the time I turned my attention to the damaged camshaft insert. It took quite a bit of filing to achieve a result I was happy with, but as it seems there will be no replacement part available, then this is the only course of action that will get us to where we want to be.

I had never really thought about it, but the camshaft is hollow, and with the insert removed you can see right through the centre to where the ignition taper is at the far end. After some trial fits I got to the point where the insert would enter the cam thread either way around, so I figured it would probably accept the whole thing now, and screwed it as far in as it would go.

Which appears to be exactly where it should be.

Having allowed adequate time the barrels were lifted off the cases and the gasket is firmly affixed which is great. The next step was to fit all the pistons to their respective bores, which is simplicity itself with everything firmly planted on the bench.

Then the barrels are placed on spacers which hold them above the crankcases while the two outer conrods get tightened to their crank journals. They are currently just nipped up and will be torqued to 10 ft.lb, then to 40 ft.lb on the next sortie.

The centre conrod is just dangling between the crank webs for now, but once the cases are together and the barrels are fastened down, the centre rod gets torqued up via the hole where the sump plate fits.

You can see that there is adequate clearance to slide the right side outer case in using the main bearing on the crank to keep it aligned, plus there will be two studs at the top of the opening which engage while there is still about 3 inches of airgap between the joint faces. The camshafts pass easily through to the left side while keeping their lobes inboard.

Obviously both joint faces need to have been coated with sealant before getting mated together, and all the various O rings which seal the oil filter cavity and the gearchange cross shaft also have to be in place. Not that it is difficult to pull the case away again if necessary, but 'planning' should mean you don't have to.

The left outer case is the last manoeuvre, and it slides over the ends of the camshafts and the other main bearing tracks along the crank. It is all extremely controllable, whereas supporting the barrels in mid-air with one hand while you try to coax three unwilling pistons up their bores with the other is nobody's favourite magic trick, and one that can rapidly come unstuck.

In preparation for the right case going back on I fitted the camshafts back into their gears with the factory timing marks all lined up. One of the first jobs once the engine is back in the frame will be to check the cam timing to see if they were factory set as close as possible to spec, and if not, I shall correct that.

After a prolonged period of locating and cleaning the crankcase studs, bolts and allen bolts, I completed the first stage by torquing the big end bearings up in two stages, as called for by Carrillo. First step 10ft.lb, then up to 40ft.lb in a single sweep. It all performed as intended, so next step was to apply a thin coat of my silver silicone sealant to both mating faces. After that I fitted the two studs at the top, and gave all the cam lobes a good coat of assembly lube, and O rings got fitted to oil filter cavity and cross shaft joint areas.

The case was then introduced to the crankshaft as the cams were guided through beneath the block, until it also engaged with the two studs, after which it was a doddle to tap gently around the periphery with a light mallett and the whole thing slid home. A very rewarding process and totally free of any stress to any parts whatsoever.

The cylinder block is of course steadied by the fact that two conrods are bolted up, but the two wooden blocks keep it just high enough to clear the studs on the outer case which the cylinder will get dropped down onto once the left outer is in place. It is the simpler of the two to fit, so a nice downhill run from here.

I only nip the fastening bolts up immediately after the case is fitted, to give the sealant a better go at curing a bit before giving them the full treatment, which I did several hours later. You can see the tiniest bead that has oozed from the joint down the rear edge, but as the outer case has a small protruding lip around its inner edge, nothing can find its way to the inside of the crankcase.

Another day - another case. Despite being late November it is another crap day with minimal daylight entering the shed, so I change glasses a lot in order to see fiddly stuff. No real tricks on the drive side case, other than remembering the O ring seals, and there are less obstructions to applying the silicone sealant. It went together easily enough and the barrels dropped down smoothly.

As I now intended to torque up the final big end, I pinched the two centre barrel retaining nuts but left it at that. If anything should somehow fail to behave I might have to lift the barrels or even remove one of the cases, so I will nail it all down after the big end is happy.

Carrillo are quite concise about how they want you to approach torqueing up the caps on their steel rods, to the extent that they describe what sort of oil they would like to be applied to the bolt heads and threads.

As it happens I have just the thing, even though it was not for this purpose that I acquired it. Clear Mechanical Oil is actually the perfect stuff for fixing noisy controls on stereo amplifiers and the like, as it not only lubricates the shafts but also addresses the oxidization which causes crackles for mostly the rest of the life of the control in question. So I guess it is more versatile than I anticipated. So the whizzo bolts got a light dose of it.

After that, and with more mass holding the crankcases from moving about, the final tighten to 40ft.lb was a cinch and we were complete inside the cases. I am not entirely sure where the sump plate actually is yet, but it will be one of the carefully bundled bubble-wrap packages stowed about the place currently. I will do a final fit of it when it comes to light, as one of the first things I will do once the engine is back in the frame is to complete the oil circuit and manually pump some oil around the engine. Such is the plan.

I bolted the barrels down and fitted the crankshaft timing pinion to its key. I then set No.3 cylinder to TDC and timed the camshafts, with the inlet timed to the dash rather than the dot. This returns T160's to the more advanced timing of the inlet cam, most of which were retarded when assembled to meet more stringent emission controls in the USA. I have no idea whether this bike had already received this benefit as it was all dismantled before I saw it. On my own from new T160 this process still did not advance the cam to the optimum timing, so I changed keyways and got another third of a tooth. Same options are available here, so that gets done early in the piece.

Unfortunately the sump plate turned into a non-event, as in it is nowhere to be found. No plate, no filter, no old gaskets, no studs. I am sure the owner will be as disappointed as I am, and while you could understand if a piece went missing, an entire sub-assembly doesn't make much sense. I have a repaired filter we can use and have found a new original plate which I have ordered, so I guess we will concentrate on getting the engine back in the frame until these bits arrive.

Before fitting the engine I decided to investigate the oil tank filter, as it has to be modified to match the uprated feed line. As soon as the filter came out I knew that the oil tank would have to be removed as well - sparkly stuff everywhere.

This gives an indication of how much of the broken piston and worn cam and follower had travelled around the oil system, so the lines and cooler are going to be treated with utmost suspicion rather than allow contamination anywhere near the engine from places it could be lurking. I also spent a bit of time repairing the main stand which was planning to migrate, despite having had some copper wire wrapped around the offending bolt. When you get the chance to access places where things are not in a good state, you gotta use the moment.

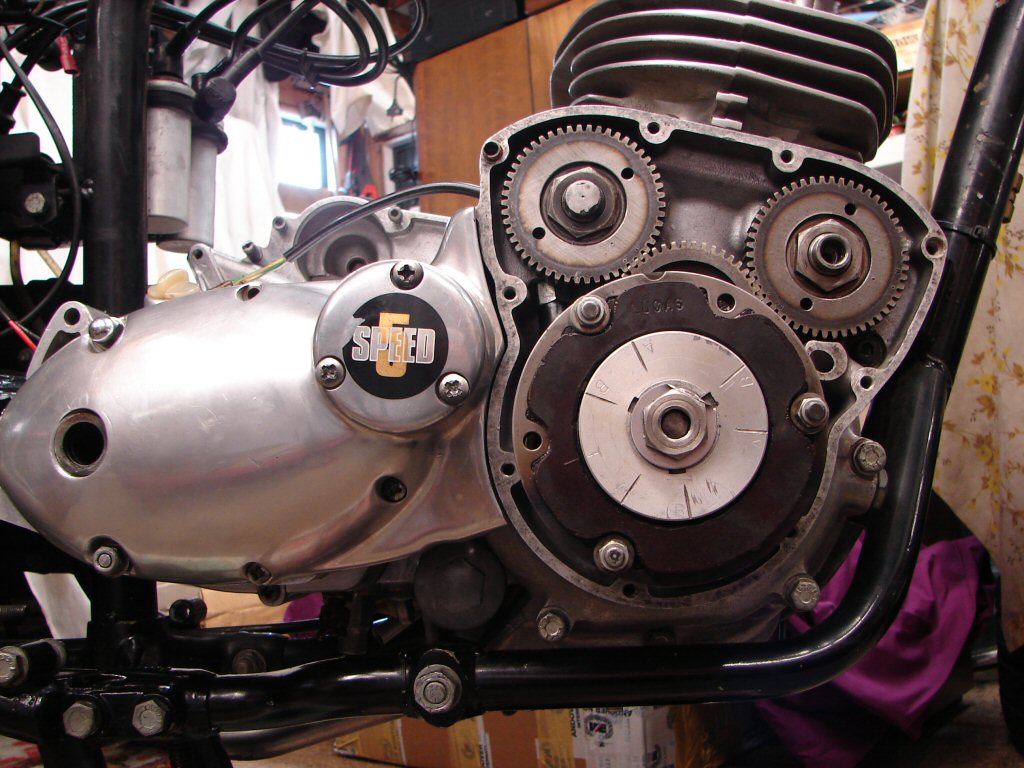

At least I did also manage to restore the engine into the frame, and have begun to assemble the gearbox, beginning with the final drive oil seal housing on the left side, after which the camplate and mainshaft and clusters can start their journey into place.

I will also begin the camshaft timing as soon as another missing part arrives, being the nut that retains the alternator rotor. I will need that to hold my whizzo timing disc.

In other news, I bust my camera, which is a major pita. For 20 years it has done sterling service, and I shall find a used one of the same model if I can. Meanwhile the photo quality may be a bit naff...

Have spent a few days on a bike instead of under one, thanks to a mate visiting from Perth who was eager to get aboard the 955 Tiger I had sorted for him, so progress has slowed a bit. Prior to that I had reasembled the gearbox internals but the outer cover refused to fit back in place. I pulled a few gears out again but they were all as they should be. It seemed that the outer ball bearing was too tight a fit on the mainshaft, and I am not one to force things if they resist. Said bearing was not a very tight fit in the outer case so I plucked it out, and sure enough the cover now fits up snugly.

It is not a problem to fit the bearing after the cover is in place but I needed to know why it was tight. The answer seems to be that the spline which the kickstart pinion fits on has developed a few ridges on the outer edges of the spline. Presumably this engine is a bit harder to kickstart than a 750 and the shaft has complained a bit. Perhaps the ratchet assembly had been a bit loose, as they require over 40 ft.lb when tightening. I shall smooth the spline before the bearing goes in on final fit.

The suppliers who had an original sump plate discovered after I ordered one that they didn't have them at all. However, and much to their credit they emailed me and said that they had a good used one if that would do. Indeed it would, and it arrived a few days later.

After some suitable cleaning the sump plate assembly got fitted back on the engine with no problems. I chose to use allen screws rather than the original stud assemblies, partly because there are no longer any bare threaded ends to get damaged by rocks and the like, but also because the original arrangement gets to be quite expensive once all the parts are added to the mix, whereas these are the same stainless allen screws I use to hold the inlet stubs to the head, so I have plenty and they are cheap. Good combination that..

It is also my experience that these sump plates are seldom removed as often as the factory recommended they should be, due to the complexity of removing the exhaust collector, so I doubt it will prove to be in any way less effective, and does in fact give a little more clearance above the collector.

A battle ensued with the gearbox. The inner cover ball bearing continued to be a tighter fit to the mainshaft than felt healthy, especially as the two are bolted up really tight by the kickstart ratchet assembly, so I had to keep tapping the bearing along the mainshaft each time I trialled the gear selection after fitting the inner cover. Because of the tapping the thrust washer at the other end of the layshaft came off its locating peg, so it all worked, but seized up when I tightened the cover. The grease intended to retain it was being overcome by the oil applied to the gear clusters, so as a last resort I used assembly lube instead, which sticks like the proverbial to a blanket, and that got us a result.

So with the gasket in place the inner cover got its final fit, after which the kickstart ratchet was torqued to 42 ft.lb using the gearbox sprocket nut tightening in the opposite direction as the counter force. All that is left now is to fold the sprocket locking washer over a flat before the clutch hub and cover can go on.

As a final touch today I trial fitted the outer cover which will keep things clean inside, and the quadrant which can be seen in the opening for the cross shaft was easily able to select all gears. That was the acid test.

I had noticed that the hose which feeds brake fluid down from the reservoir to the rear master cylinder is totally perished, so I shall replace that before the engine mounting plate goes back on. Much easier both with that and the oil tank missing - still to be flushed out.

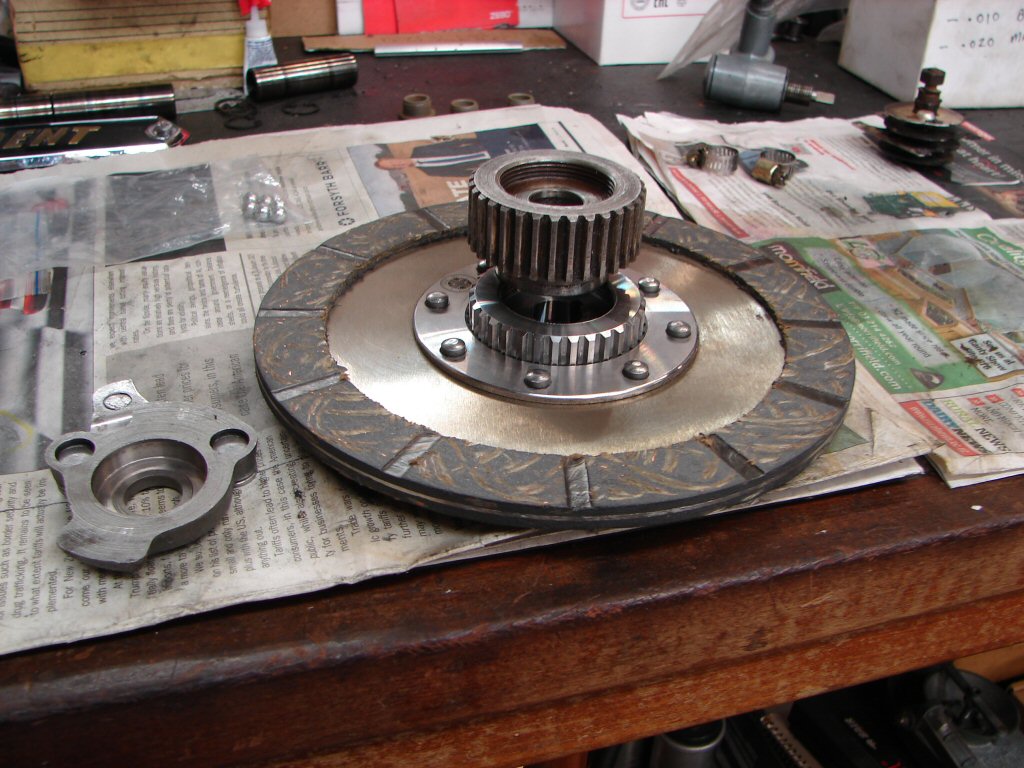

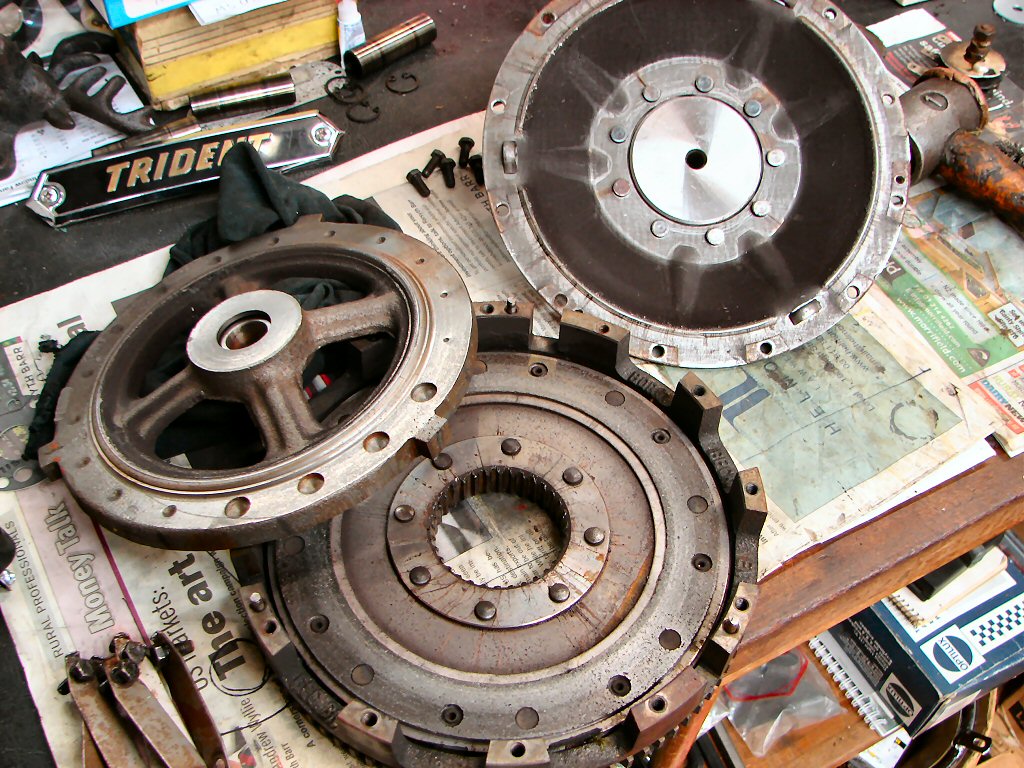

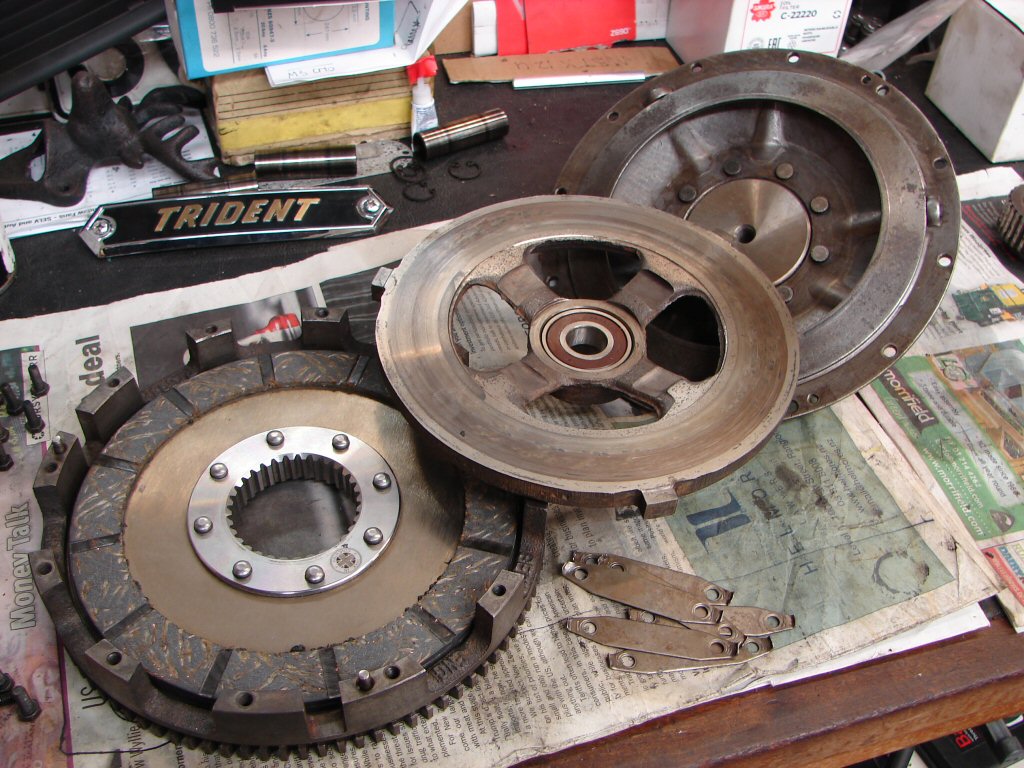

The next logical step would be to fit the clutch hub and housing, but I had already noticed that the hub splines are not up for another term of service without risking a total failure, and as expected the clutch plate splines are in the same boat. I have personally experienced several failures of these splines on my T160 in the past, but pleasingly the current parts available are of better quality and construction. The plate in particular is one of a batch made by Clive Blake in the UK and features a thicker lining which allows the clutch spring to go over-centre when fully disengaged and thus lightens the clutch action. I have yet to experience one, but as it is the only type available here I guess we are going to.

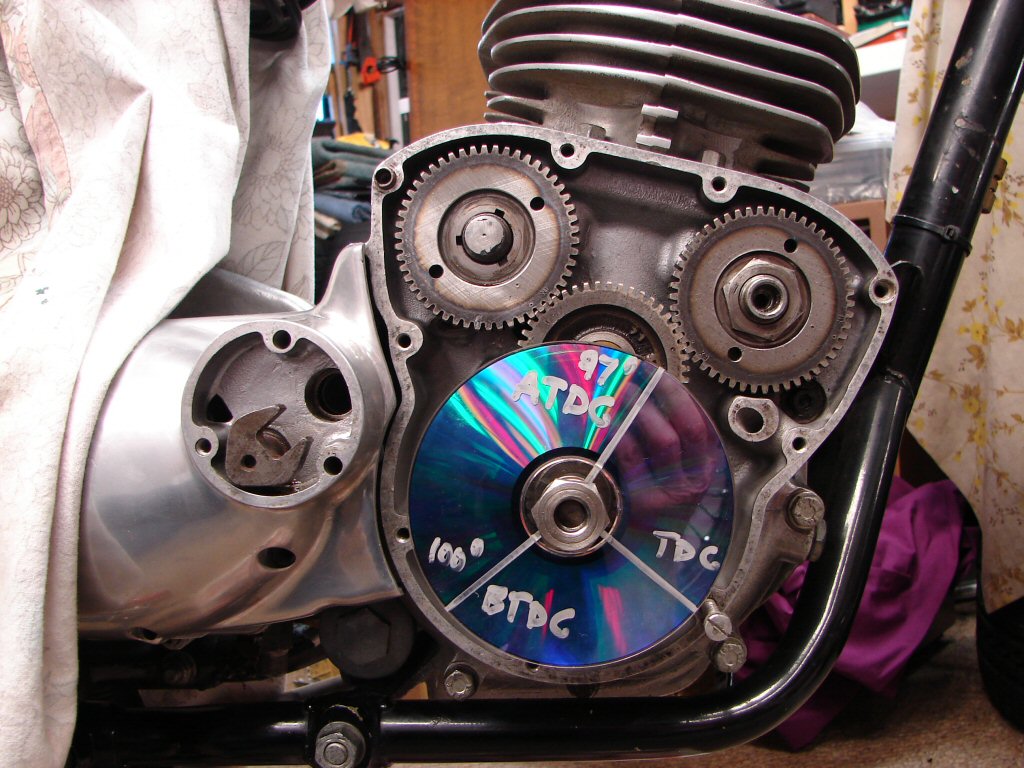

While we await those parts I decided it was time to deal with the cam timing. This entailed first removing the alternator mounting studs which in turn requires removing the seal nut that the alternator wires enter the timing case through. For a first time it turned out to have been loctited in, which made matters quite difficult as you can't really get a spanner on it, let alone apply much pressure. By removing two timing gears I managed that bit and the rest of the process went smoothly using my non-factory method of centre-lobe timing which has given brilliant results since I began using it. The real bonus is that it is far simpler and requires no fancy kit to undertake. For anyone interested I describe the process here

Any old DVD is used to make the timing disc and only three marks are required. The two critical points are the max cam follower lift for inlet and exhaust, while the TDC mark is the reference point and much care must be taken to establish it beyond any doubt - which I do by repeating the setting several times in a row. To be sure to be sure...

Pleasingly both inlet and exhaust were exactly where I wanted them to be, having already advanced the inlet cam by one tooth from where the factory assembled it. As often as not they can still be a bit off and need a 1/3 tooth adjustment, but these are fine. I don't know where they may have been set before the strip, but they are right now at least.

Now I have to refit the cam gears properly after which the alternator goes back in and the timing case can get buttoned up.

Two cool things happened during this period. First the alternator retaining nut showed up inside the the Boyer ignition pickup box, and second, I managed to buy another camera exactly the same old model as the one I broke, so normal transmission has been resumed.

Yay.!

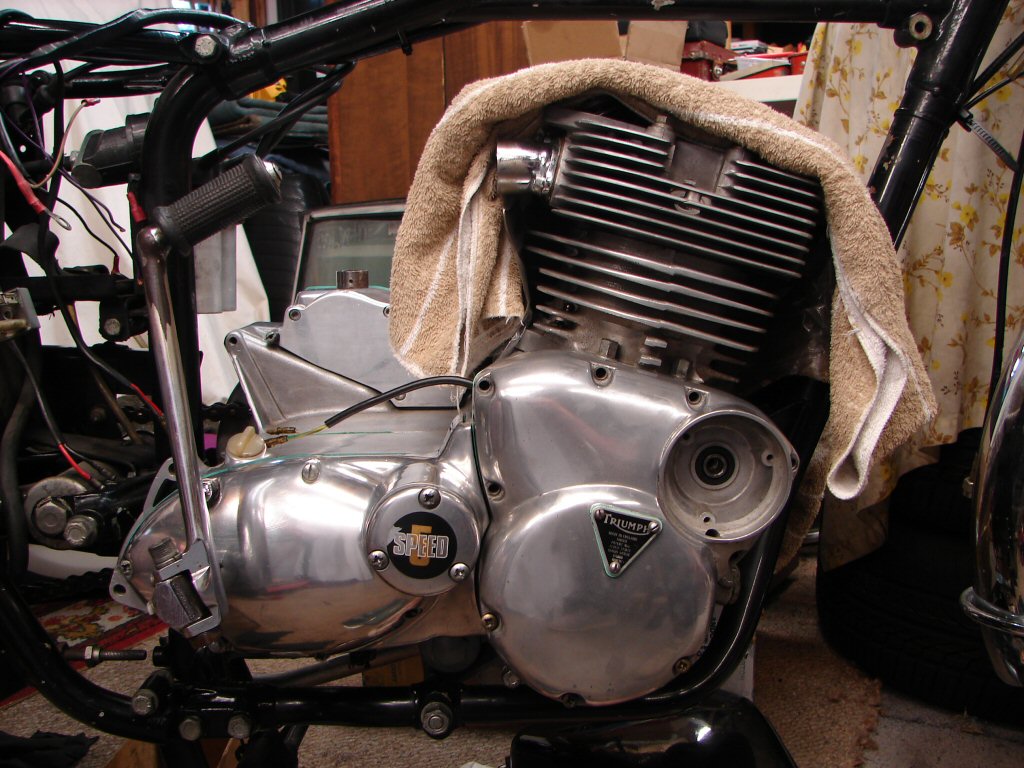

So here we have the timing case pretty much sewn up, although I need to fit a new camshaft oil seal before the cover goes back on.

Due to a few parts having shown up missing I have begun trial fitting covers before assembling their internals completely, so that I don't have to do something twice.

Also I had already decided that the kickstart return spring, still fitted to the kickstart shaft, was past its best-by date and would likely not last very long before its inevitable failure, so best we do it now. As the new one arrived yesterday I would be able to complete the assembly of the gearbox outer cover next.

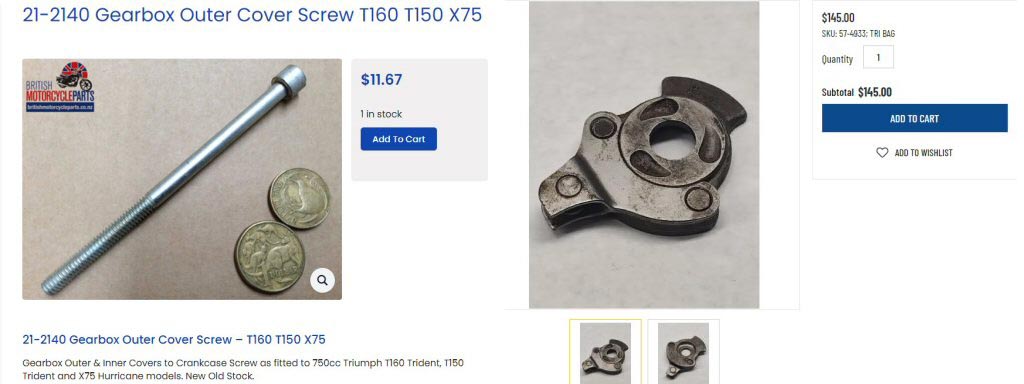

As it happened there was a part missing from the gearbox outer cover, being the very long top screw that holds outer and inner covers to the centre crankcase. At over 4 inches long and with an elongated head its a pretty significant screw this one, so once again, strange it got lost.

And - the search for the missing screw led me to tipping out all the remaining fixing screws which were jumbled up together along with the clutch adjusting bits from inside the outer primary cover, and they were also missing a significant part, and one that is now very hard to get.

None less than the clutch operating lever itself.

As luck would have it the screw was readily available, and I have already ordered it from the source shown, along with a grommet for the alternator leads where they exit the crankcase, probably being the world's most expensive grommet at nearly $20, but I guess that is what you pay to get a batch of such things from the UK.

The new-old-stock clutch operating lever pictured as available from Baxter Cycles in the USA converts to NZ$250 not including freight, but as it is one of few left in the world it may be our only hope. Unfortunately it sometimes turns out that when you attempt to order some of these rare parts they suddenly discover that they actually have none left.

There are now too many of these bits missing for me to consider that they were somehow accidentally overlooked.

That is not a happy observation for me or the bike's owner.

Perhaps it was a corresponding lowering of my vibration at this point, but I then spent a good part of an hour trying to convince the rear chain to fit, as despite a week soaking in old engine oil the joining link needed something nearly nuclear to get it apart, after which some remedial treatment was needed for the link itself, so that was a bitch.

While I did win I am still unable to assemble the clutch housing as the new clutch hub has not arrived.

Oops. I see they are closed for xmas, so we are on hold with the drive side until after 12th Jan. Oh well, I can still fit the clutch housing I guess.

This thing is getting a bit gritty.!

I finished today's effort by cleaning the pillar studs inside and out and fitting them to the barrels, albeit not yet tightened. The majority of the studs had quite tight internal threads, probably down to baked oil which had found its way into the threads. That in itself suggests that either the cylinder head or rocker box gaskets may have compressed enough for oil to leak down the head studs at some previous stage. Quite common before solid gaskets caught on.

The extra resistance in these threads can interfere with the ability to get a good head tighten, seeing as how they only go down to 20 ft.lb anyway, so they all got a good run through with a tap, although I never touch the external threads on the pillar studs as they have a "rolled" thread so a standard dye nut removes valuable thread. These are the most critical threads on a triple cylinder as the alloy tends to lose strength as a function of heat cycling and once the threads strip it takes a serious engineering approach to cure the problem.

I will temp fit the oil drain dowels next and do whatever it takes to make the original Hyde copper head gasket a nice sliding fit over studs and dowels, which they virtually never are, so a used gasket is most often a better starting point than a new one.

Next step the clutch housing got fitted, wiring harness tidied up back to the seat area, pillar studs tightened and head gasket dressed around the studs but not the drain dowels yet, and head trial fitted to ensure it is all sitting as flat as it should be.

Seems like it is, but if not, leaving it overnight with 10 ft.lb on just the outer bolts will begin the settling process of the gasket. There will be a coat of copper gasket spray given to both sides of the gasket when the final fit happens, so a bit of "training" will ensure it has the best chance to do its job.

The gearbox cover then came off and the kickstart oil seal got driven out. The new spring was fitted to the kickstart shaft in the correct position - there is one - and after oiling all the bits in the cover the shaft went in and the new seal and housing were driven back in place. The kickstart lever then got fitted as the spring has to be preloaded before the cover goes on and the leverage provided by the lever is necessary. Grease was applied to all the gear quadrant and kickstart ratchet teeth, and also to the new gasket before sliding the cover back on while the gasket held itself where it should.

Happily it all behaved as described so the cover was fully tightened apart from the still missing screw which is on its way. I had sliced the protruding excess gasket off the top of the inner cover gasket, and now see that this one is sticking up more than it should too. It may just be the shape of the gaskets, but I will loosen the outer cover again when the new screw is being fitted to see if the gasket wants to drop a little, otherwise it will get trimmed too.

Bloody green gaskets...

The gearbox screw turned up so I loosened the cover and managed to settle the gasket a bit lower before tightening the whole thing. Although the neutral light switch is not seemingly connected to the idiot light it still obviously has a hole to plug, so I will set it to have minimal contact with the camplate. When that is done I can fill the gearbox with oil.

I treated the gearbox and timing covers to a mild polish while trial fitting continues. There was only one of the nine timing cover screws present, but I was able to find a set of the three long screws at the bottom, and may also have some old screws to fit the top six, but if their heads are too far gone to grace this cover I will resort to allen screws which are a fraction of the price of genuine phillips head replacements.

Next step will be to fit and time the Boyer ignition pickup and run its wiring back to where the unit is located by the battery. The bike features an industrial type bridge rectifier - seen to the left of the kickstart lever - instead of the original finned Lucas job. This one had been suspended from the spring which once held the flasher unit, which I shall change. I had no less than three of these industrial types fail in relatively quick succession, despite adding a heat sink to the last two. They melt easily, and without being bolted to a reasonable piece of steel frame I can only imagine this one would be headed for the same fate. I refitted the old Lucas job to mine and have not had to visit it since. I put this particular popular modification into the "they say..." category, as the modern version is far less capable than the factory fitment, so once again - I think the factory got it right.

Having found a full set of screws for the timing cover I oiled all the gears within and also checked the airgap around the alternator rotor which was as it should be, and the cover went on with its new greased gasket. I managed to oil the end of the camshaft as well, so it would happily pass through the new oil seal.

The pickup wiring loom then got threaded through to the aperture, and with the engine set to firing position on the nearest cylinder the magnetic rotor went into its taper. The pickup plate was then fitted so that the screw head holding one of the magnets was visible through the provided hole. Pretty simple setup for the Boyer seeing it fires everything all the time. Next job will be to run the pickup wiring all the way back to the Boyer unit.

After waiting some days for the 'summer' rains to slow down a bit I was bracing myself for a pair of jobs I have a major aversion to. Cleaning a glittery oil tank and filter, plus modifying the oil tank feed to uprate the line size from 1/4" I.D. to 5/16". Because the T160 oil filter is unobtainium currently the existing T150 item has to have its delivery drilled out, and the retaining nut for the feed pipe - which is available - also drilled out to accept the larger pipe. While it is not too hard to drill the hole in the nut, the new feed pipe now has to have its flared end filed down in order to fit inside the threads of the nut. Its about the same fun level as gnawing your own arm off.

I began the tank with lawnmower petrol - its cheapest - then degreasing fluid, then water pressure, and when it has dried it will get the air gun as a final insult. I was not prepared for just how much metallic stuff came out, but then remembered that this engine had attempted to digest its own camlobe and follower, so I guess this is it here..

The tank oil filter had already had its outside cleaned before the drilling process began, then had another internal cleanup after four drill bits had passed through the boss in moderately quick succession. I then use another four drill bits to open up the nut, stepping up by 1/64" at a time, in order that things do not drift off centre, as there is absolutely no room left for errors.

The final tedium is hand filing the flare down until it will fit inside the threads, we are about halfway here. This is when you find that these things are not concentric at all, so you have to address that in the process.

It better be worth it...

Another session with a coarser file sped progress up considerably, then after smoothing and contouring the edges the pipe was able to be coaxed through the nut. The pipe was not keen to rotate inside the nut, but by trial and error I will be able to locate the outlet at the best angle to allow the feed line to sneak into alignment with this fitting.

The air compressor was now brought into play to dislodge any more debris from inside the oil tank, but nothing came out despite a pretty thorough attack from every possible direction. It pays to be as sure as you can be. Many rebuilds have suffered the ten years accelerated wear test when some fine grit got circulated through the new bearings on the first start.

Filter and pipe union got added to the tank and it was ready to be installed.

Checking the bike end of the equation reminded me that I had to replace the brake fluid line from the underseat reservoir to the rear brake cylinder before the oil tank got in the way, so I removed reservoir and line which was badly cracked at both ends. That might explain why there was no fluid in sight.

The new lines are larger in diameter than the originals, so the two P clips that support the line, one either side, need to be a size larger. As it turned out, the left one had split in half and the right hand was absent, so it will all be better after than before. The Japanese proved that making things well supported made sure that everything remained where it should for long periods of reliable service, so I place some importance in such detail work.

Cleaned out reservoir with new fluid line and retainer clip.

It is much easier to work on the rear cylinder after removing the rear footrest and muffler mounting plate, so that came off, revealing that the master cylinder pushrod had been put together incorrectly. It may be because of this that I find the cylinder also seems to be locked solid, as a locknut was at the wrong end which had allowed the large shaped nut that fits through the rubber boot on the front end of the cylinder to wind itself against the rear of the cylinder body, so it all has to come out to see what gives. The cylinder body has either been chromed or is an aftermarket type - perhaps stainless - which could influence things either way.

What we are doing here, besides an engine rebuild, is 16 years of delayed maintenance, so other problems are bound to come to light, but we can only deal with them as they do.

It does make some days feel more like going in the wrong direction, but thats just how it is.

For a bit of mojo restoration I fitted the oil tank and positioned the feed pipe to sit at about the only angle where the line can be fitted without interacting badly with other things. Because the T160 has the entire engine unit rotated slightly forward, which allowed the lower frame rails to be raised by an inch - a racing benefit - things around the oil filter outlet are quite restricted, so they put an angle in the outlet pipe itself to make things workable. Pretty much means that you can't remove the filter easily/at all without pulling the tank out.

I gave the tank the briefest polish and a new pair of screws in the badge to make it look bright and shiny.

Raises my spirits to see it there.

Assembling of the cylinder head continues with alloy rocker box gaskets in place and the Hyde pushrod tubes figured out. Quite a bit of compression of the seals so we hope not to encounter any leaks. I am averse to using silicone sealant on the pushrod tubes, and so far they have complied, but these use one joint which is the base of the tube against a fibre washer, which may need more convincing.

The rocker boxes would have responded to a soak in an engine bath, but are mostly invisible once the engine is complete and the tank is on, so we shan't sweat. I will leave the oil cooler off until the valves are all adjusted as access is far easier.

The inlet rocker box was well behaved so now we have everything where it needs to be and the head bolts are all torqued down to 20 ft.lb. This would normally be the time to set all the valve clearances, but without our clutch hub there is no connection between the kickstart and the engine, although I guess I could turn the engine backwards by using a monster spanner on the crankshaft sprocket nut which would otherwise just wind itself off.

Actually - that is a bloody good idea. I have been mindful of keeping the engine at firing position on No.1 while the ignition timing was being finalised, in case I needed to alter something, but it now seems that the Boyer may get the heave-ho in favour of a new Tri-spark, so that has all gone out the window. As has the wiring work, as there looks like being a new wiring loom also on the cards.

I'm thinking that progress will be going backwards again.

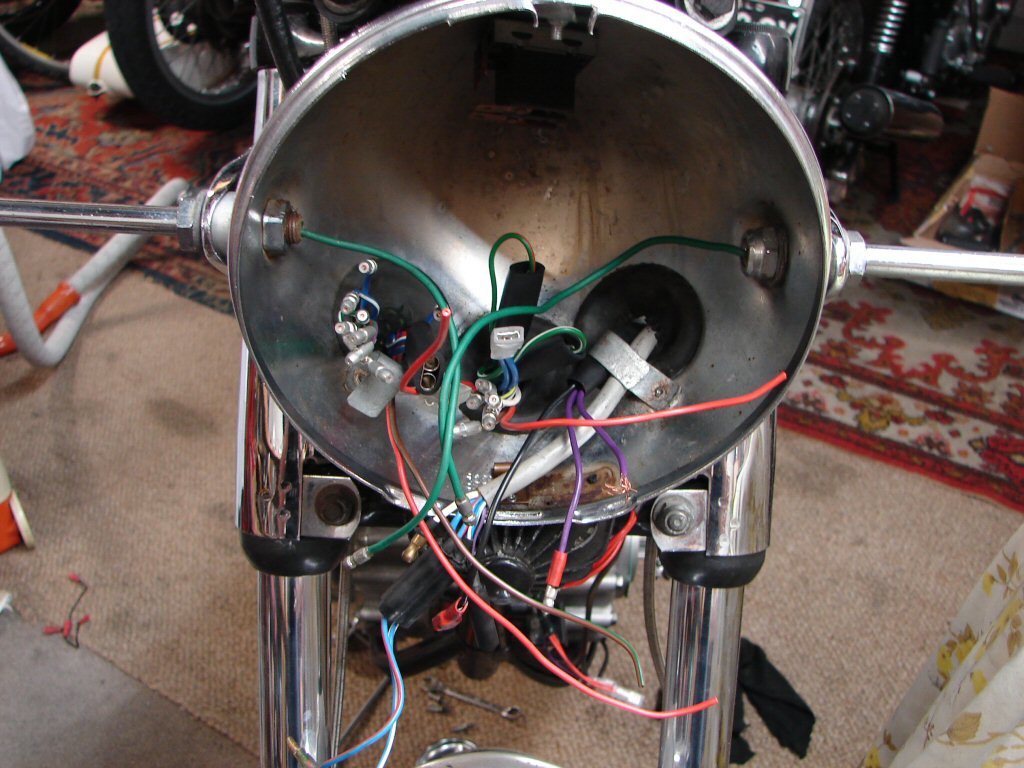

In preparation for the wiring rehash I have removed all the instrument cluster and exposed the ignition switch, which will be replaced as the keys were lost. This also revealed that all the idiot lights are just empty lenses, and the "wiring loom" was a piece of 5 core flex. Electrics were minimalistic on this bike. In the interests of perhaps fitting or refitting an electric starter the wiring loom has become the easiest route to reinventing all the other wires, so perhaps the oil light and neutral light may return as well.

Meanwhile things are looking kinda sad up the pointy end and I will have to identify what the wiring colours mean in the non-standard switchgear.

The problem with the rear brake being inoperative turned out to be the last thing you always suspect - the flexible hose is totally blocked.

Having removed it I was able to pump the cylinder enough to get rid of most of the old fluid, the rest will get bled out as soon as the system is restored. Locknut is now applied where it should be and the cylinder can be refitted to the bike where the rest of the process will be completed.

It is pleasing to note that the length of the new fluid hose supplied is significantly longer than it needs to be, so it can be cut to exactly what is required. This is a practice which used to be a lot more common than it is today, but is very welcome when one installation proves to be very different to another.

I tend to leave a fair bit of extra length tucked under the oil tank with these, in case the ends crack - but the golden rule is that the entire length should be a downhill slope so that it can be successfully drained just by releasing the lower end without having to disturb any other stuff.

The xmas break is over and parts are beginning to arrive again. Am having to source from several suppliers as nobody has everything any more, and some parts will not be easily restocked - if possible at all.

The new clutch plate is a Clive Blake item, with thicker lining material which allows the clutch spring to go over-centre and thus makes for a lighter lever action. We will see. The amount of wear on the teeth of the old clutch hub spline is immediately apparent when compared to the new one.

Also in the pic - a New Old Stock clutch operating lever which was a real find and close to home, so the absence of the original has ceased being a potentially large problem, as they are in scarce supply world wide.

And then the major order of parts including a number of items I was not initially intending to be fitting to the bike under the original brief, but one has led to another and so it goes. A repair becomes a restore in very few steps.

Having an electric start would make the finished article much easier to manage for the owner, and I do have access to a complete and new T160 starter - the original from this bike is long gone - but I had reservations about the Lucas versus 1000cc's of reluctant British gubbings. Considering the estimated price of the new original it seemed no more expensive to instead fit a Madigan unit, with a motor designed to prod a four cylinder Ford Ranger into life, and therefore pretty much guaranteed to do the job in all weathers.

The absence of any wiring left at all relating to an electric start dictated the need for a new wiring loom, so we might as well revert to a few more stock electrical arrangements. Much of all of the above is to be seen in this modest carton of parts hot off the press, whose combined value is pushing 3 grand.

The budget just took a big hit...

The game is back on, and the first thing to go was the Boyer. From here on the wiring becomes a critical issue, as we have to make the wires on the new harness all reach to where they are needed, so anything with wires will be in place first.

I fitted the Trispark rotor as prescribed with a 22mm gap between the top right threaded hole and the steel pin in the rotor, as it is here. First issue was that the supplied fixing allen screw bottomed out in the camshaft thread before the rotor tightened, but as the old Boyer screw had a pronounced taper at its inner end I tried that instead and we have a match.

As it happens, the crankshaft is still at firing position on No.3 cylinder where it was for the camshaft timing, and now needs to be moved to the timing mark for No.1 cylinder, but as the primary drive is about to begin its assembly process I shall wait until the kickstart is operating to do this and the valve clearance adjustments. This is a trial fit.

On the other hand - or side - this is a final fit. The new clutch hub has passed quality control and been bolted up using top gear and a block of wood under the rear wheel. I only use silicone sealant as a thread locker on both the hub nut and the three screws which hold the clutch cover, as silicone handles vibration better and the hub being both on a taper and with a keyway is hardly going to attempt to move, unless I have to remove it again for any reason, in which case that too will be a more agreeable situation than with loctite.

The black marker visible on the top rear edge of one tooth of the spline lines up with the keyway, making that easier to find when fitting, but it also marks the optimum position for the two splines to mate up together when the clutch assmbly goes on, and the clutch plate has a matching mark. Not all teeth are created equal...

We then ripped the clutch assembly apart, which has been lurking in a carton until this moment arrived. The only oil contamination had come through from the primary along the spline on the clutch cover shaft, and I fit an O ring to dissuade this from happening in future. Other than a good clean up the only parts which will be replaced are the plate and release bearing.

The plate that was fitted is a sintered iron type, as was developed for drag racing, though I find that their action is not as pleasing on take-up as conventional linings such as the new one has. I find that the splines between hub and plate are the fastest wearing parts in the clutch, so the lining material is academic in my opinion. I can understand that with a big bore engine and the intention of racing it one would think the sintered job a better option, but it would never have been my choice.

For similar reasons to the above I was concerned that a heavier duty clutch spring may have also been adopted, but having cleaned and measured its thickness I am more than happy that it is a stock item. Heavy springs are a bitch for road use, and with the thicker linings the new plate has it should prove to be a pleasure to use.

The clutch appears to have had some post factory balancing done, so care will be taken that it goes back together in exactly the same orientation it came apart.

Once I got into it there was a lot more oil residue than it looked, but mostly inside the assembly, meaning it had come in via the pullrod seal. Thanks to the sintered plate it seems it kept working, as it would have taken some miles to do this. Took some time to clean it all, and despite the oil there was a fair amount of rust to wire brush off, presumably from the time in storage.

I replaced the bearing in the pressure plate and then made a series of number punch marks so that I could align everything as it got assembled, including being able to fit it on the exact tooth of the hub as it went into place. The original locking tabs wire brushed up and were in good enough shape to do a second tour of duty.

With the pullrod fitted it slid into place like a happy thing and will now wait while a number of other preparatory things are done. First will be to strip the oil pump to make sure it has not suffered from the sparkly oil, and once I am happy with that it will get fitted before the inner cover as that is the easiest approach.

The inner gasket got a trial fit, as they have been a bit less accurately made of late, but this one will do the job ok. I also fitted the gearchange cross shaft as that will enter its new oil seal in the inner cover easiest in that order. I cannot time the cross shaft until the primary chain and sprockets go on, before which I will complete the oil system and pump some oil through the bearings while I have easy access to the drive gear.

Meantime I slung the wiring loom along the frame to see where things were going to end up. For $500 it is not a very good loom, with old bullet type connectors in the headlight area, but more annoying still a few of the wire exits are placed badly and will not reach to where they should. It is a sad observation, but I doubt I will be able to continue doing this sort of work in the not-too-distant future, simply due to the increasing shortage of decent quality parts. Too many of the quality manufacturers are gone and the current level of quality control does not even begin to reach the level of the price increases that my suppliers have no control over.

There will need to be a bit of nutting out of the wiring as regards the switches the bike has. The left side has a T150 switch which is used for high/low beam, but the horn and indicators have been moved to a small aftermarket switch also on the left side. I am hoping that the unused horn button can be repurposed as a starter button, but first I have to unravel the wiring colours.

Never a dull moment...

Well, as it turns out there is no working button on the indicator switch, so the original horn button is still in use for the horn. Not sure if the extra button on the LH switch unit can be wired up to actually do something - I believe it was intended to be used as a headlight flasher but have never known any to do such. Shall investigate in due course.

The oil pump got primed with oil then flushed with CO contact cleaner, but no signs of any sparkly bits. When opened up the pressure side was clean as, and despite a few more flushes nothing came out of the scavenge side either. Hard to imagine that so much got into the oil tank without there being any residue in the pump. I guess it just remains in suspension until the oil stops flowing and it settles out.

The end plate got its oil supply hole opened up to match the larger feed pipes, then got surfaced to remove any excess wear. Quite happy with the result.

The oil pump now got fitted to the crankcase and the first big O ring settled into its recess. The non-factory O ring is fitted to the clutch cover shaft at the rear of the spline, and will get compressed between there and the end of the cush drive spider, so no more oil into the clutch housing. It is a stock T160 part as it happens - for the gearchange cross shaft sealing between the crankcase sections.

The new gasket is greased both sides and the cross shaft is fitted so that the oil seal will be easier to coax over it without the risk of any tears in its feathered edge. While the new seal fitted easily into the inner case, it seems to be a very tight fit when presented to the 5/8" shaft, and it is of a different construction than what used to be supplied, which had a steel backing. It is however of the same slim nature that this seal must be to fit into the shallow recess next to the needle roller bearing.

I had the cleaned up inner primary case ready to go, with its two new oil seals and the second big O ring for the oil pump sitting in its groove. Neither of the two needle roller bearings needed replacement, and were an excellent choice to have been a part of the original design brief. They do tremendous mileages with little wear, so long as they get their oil needs met.

When the inner case was slid into place, carefully guiding the oil pump O ring so it didn't get its edges nipped, I paused the assembly so that the gearbox end of the cross shaft could be fitted to the spline at that end. This requires the shaft to be drawn toward the primary side just far enough to allow the link to slide into place, but it came out just a fraction too far and popped out of the oil seal. It was such a tight fit that I could not push the shaft back through the seal, so I took the inner case off again, to find the the oil seal had pushed right out of the case.

Hmmm - this seal was way too tight, and now it was captive in the middle of the cross shaft and would not fit over either bearing surface at the two ends. I had to cut the seal off with sidecutters. I had a look through my stocks of seals and found two cross shaft part numbered items, one the same as this and one of the original type. Some careful measurement showed that the original seals are designed for a 5/8" shaft, while the new ones are only big enough I.D. to fit 9/16". I shall use the original one and hope that I can source some more for my stock.

This photo was taken before the first fit, so it has the wrong oil seal still in place, but it got chopped off the shaft a few minutes later. With the proper seal in place I tried fitting the inner case for a second time. The shaft went through the seal much easier, but I am still not wanting to risk it coming right over the bearing surface and off the seat, so I halted progress for the night as other matters were requiringing my attention. I do not recall having the slightest trouble with this seal when I rebuilt my T160 in 1991, and everything is still in there and doing its job. I'm guessing it is just that the wrong seal was supplied, but being the newer design I chose to use it.

Here are the two types of seal I have been supplied with under the same part number, so it is worthy of note that parts can look seemingly correct at a glance, but not owe any real connection to the original part number. Both have the same O.D. so were a good fit in the cover, although the steel-backed one was firmest with nothing to compress on its outer edges.

I may have had these seals for some years, as they are not often required unless addressing a total strip. I think I have found some original type still available so I will restock while I can. No idea what the other seal might be from, but it does not seem to be any T160 part I can identify.

During the fitting of the inner cover for the second time I was easily able to guide the cross shaft into the spline at the far end, but only did so a mm or two while I lined up the 'foot' for the gearlever to mate with in the primary case. The idea is to align the lowest tooth of the foot with an alloy boss which is conveniently placed below it, although I doubt that was its only reason for being.

Once I was happy that it was all exactly where I wanted it to be I lightly tightened the spline retaining nut. I never tighten things up completely on the first try, as there is always a chance that something you missed may prompt you to take it off again, so no point in making life harder until everything has been considered.

For the same reasons as above, the inner case got nipped up without final tightening while I fitted the oil pump drive gears to ensure it all meshed as it should. After that the outrigger bush which supports this end of the cross shaft went on so that there were no surprises when it gets its final tighten.

While I always trial fit major assemblies, this engine is requiring an even more critical approach because I did not personally strip it down in the first place. That is when you find any signs of things in distress, or not mating up because of a bruise on their edge, blah blah.

Threads get tapped and hand tightened to make sure they are not binding, and if so - why. There is really only one proper way to repair things that are damaged, so that is what you do. We want whatever type of machine we are working on to be reliable and a pleasure to use, and doing it right is where the art is.

With the arrival of my preferred type of clamp for soft rubber hoses I was able to complete the assembly of the rear brake. I keep a range of sizes for use in those places where a jubilee just isn't the right choice. This is one and now it is finished, albeit not tested and bled yet.

I will dig out the Hyde rearset footrests and fit the right side with brake lever at the next opportunity so the bleeding process can proceed.

I keep changing the order of work as new priorities occur. I need to complete the oiling system so that I can pump oil into the crankshaft bearings, and this needs to be done before the assembly of the primary drive can continue.

There will be a new larger bore hose from the oil tank to the engine in keeping with the upgrade, but I had noticed that the existing scavenge line from crankcase to rocker feeds while being a 3/8" bore is very thin walled and has previously flattened out on a bend. I will fit a new hose of proper dimensions to prevent that, but find I only have 3/8" I.D. hose rather than 7/16" I.D. hose which is needed to fit over the steel pipes at both crankcase and rocker feed points. The steel pipes are 3/8" I.D. which means they are closer to 7/16" O.D. and my 3/8" hose is not going to play ball. I keep forgetting about this quaint old custom of British bikes, and often the required size lines are kinda scarce.

Not today though, so the order has been made and I shall have it in a day or two max. The two rocker feed lines are all cracked and throwaway but I have those covered.

Now that I was stymied for a day I figured I might use the pause to fit the brake lever and get the rear brake completed and off the unfinished list. I dragged the Hyde stuff out of its particular box and spread things out. There were a pair of large rubber bobbins whose purpose totally eludes me, but the rest looks pretty self-explanatory.

The footpeg rubbers are pretty much past their best-by and the brake lever could do with some paint, but otherwise everything on this side looks pretty workable. I had to pull it all off again after the first fit, as the peg was not tight enough and the head of its bolt is sandwiched between the Hyde setup and the original engine mounting plate.

All good now.

That would allow the bleeding of the rear brake, so I cleaned up the rear disc pads and refitted them, added some fluid and they bled up AOK. I used to lower the caliper so as to have the bleed nipple at the very top, but lately I am getting good results without needing that step.

I repaired the rear brake light switch and adjusted the actuating screw, then a bit of rust treatment and a squirt or two of satin black got the pedal climate proof, plus a cleanup of the rear footrest mounting plate and that job is complete.

However, I found another finishing touch. Amongst my assorted rubber parts I found a pair of BSA pillion peg rubbers, which proved to be a perfect fit on the folding footpegs. The BSA logo is hardly noticeable on the front and back edges, but I guess they can claim some right to be there seeing the T160 borrowed the Rocket 3's slanting cylinders.

Fair play and all...

It can be seen that the wires for the brake light switch are not long enough to reach it, nor would they have reached the original, so I shall need to make up a pair of extended wires to make that work. Otherwise the wiring is gradually assuming its place amongst the general scheme of things as progress dictates.

Next I chose to complete the cylinder head assembly, most of which was only to adjust the valve clearances. When in the first stages of this I fit the six allen screws along the front edges of the rocker boxes without their alloy washers. These are then fitted before the covers go on after valves are set.

To my mild annoyance the very last screw decided to strip its thread as the tension reached what is needed to squash the washers out and seal potential oil leaks. Luckily though, it was the last one, as that can be helicoiled without removing the cylinder head.

Phew.!

Here we are tapping the thread for the helicoil, having used a few smaller drill bits to clean the old thread out then reach tapping size, and I placed a small screwdriver in the near thread to give me a guide for keeping the tap perpendicular. You can handle doing this in one plane, but not two at right angles simultaneously. I got her indoors to be my eyes and keep me parallel to the screwdriver until things were far enough underway that it would continue thus, while I concentrated on keeping it vertical.

It worked perfectly, so after cleaning the alloy rocker box gasket and applying new silicone sealant the rocker box went back on. Then all the head bolts got torqued in the correct sequence again and I adjusted all the valves, refitted the round inspection caps, then fitted the covers with their new gaskets. I do not use any sealant on the first fit, and wait until the engine has run to decide if they need any or not. If not I then give them a smear of grease so they will come off again when needed without ripping.

The rocker oil feed pipes were then trial fitted with their original copper washers, as I will need them to be in place when the oil lines join the mix. The two small lines that carry the oil into these pipes are shagged and will need replacing. When that is all getting its final fit I will also add the new copper washers that were included in the gasket set.

As the new length of oil line arrived today I began the hideous job of attaching the feed and scavenge lines replete with their respective protective springs to the two pipes which exit beneath the crankcase and between the lower frame tubes. There is bugger all manoeuvring space down there so everything has to be managed carefully and has to want to fit before it will. Happily it did, and I am now at the point where the lower clamps are fully tightened, but the last job will be to add a sturdy cable tie behind the clamps as an insurance that neither hose will be able to slide off unless they both do at the same time. I figure the chances of that are as slim as anyone could make them.

I had been pondering how I would be able to flush the oil cooler to ensure that no sparkly bits would enter the oil tank again. This needs to be done in the reverse direction to normal flow, as the internals of the cooler are quite restricted, and it would be counter-productive to risk forcing any crap further into the cooler rather than out of it. The oil lines are too neat a fit to make swapping them end for end, then doing what I do with every oil change. After draining the tank and primary, I refill them both with new oil. The scavenge line is then disconnected from the top of the oil tank and placed in an ice cream container. The engine is then started and the remainder of the old oil from the crankcase sump and the cooler is bled off while it is still quite warm.

And there you have it - of course.!

I will fit this cooler to another bike's scavenge line when I am changing its oil, and bleed two coolers for the price of one.! Only about 2 litres of oil will be wasted, where one usually is anyway. Bonus is - the oil will still be hot, and there is no shortage of pumping pressure available from the triple oil pump. I have two T160s that would benefit from an oil change right now, but I will use the one with the cheapie Castrol GTX rather than blow a few litres of expensive synthetic away... lol.